10 reasons why industrial robots are the future of manufacturing

Industrial robots are no longer just a concept from science fiction; they are a reality that helps companies boost efficiency and reduce costs. If you’ve considered using robots in your production processes, here are 10 reasons why they deserve your attention.

1. Increased efficiency and speed

Industrial robots can operate 24/7, reducing downtime and increasing production output. Additionally, robots maintain consistent speed and precision even with complex tasks, making them indispensable partners in large-scale manufacturing.

2. Cost savings

While initial investments may seem high, robots quickly pay for themselves. Fewer errors, lower labor costs, and higher productivity are exactly what every company needs. Robots’ ability to avoid mistakes also means less waste of resources such as materials and time during production.

3. Improved quality

Robots are designed for precision. They help improve product quality, reduce defects, and meet even the most demanding production process requirements. The consistent operation and reliability of robots enable standardized quality throughout the manufacturing process, enhancing the final product while reducing warranty issues and returns.

4. Production flexibility

Modern robots are highly adaptable. They can be quickly reprogrammed to perform new tasks, such as assembling products of various sizes. This makes production more flexible and allows businesses to respond faster to changing customer demands. Additionally, robots can simultaneously work on different products, ideal for companies requiring variability and rapid reconfiguration of production lines.

5. Workplace safety

Robots can perform hazardous tasks, keeping workers away from risky conditions. This reduces the number of workplace accidents and enhances overall safety. Robots can also work in challenging environments such as extreme temperatures or toxic areas, where human labor would be difficult or dangerous. This allows employees to focus on safer and more strategic tasks.

6. Lower energy consumption

New robots are designed with energy efficiency in mind. They reduce the environmental impact of production and help save on electricity costs. Automation minimizes wasted energy since robots only operate when needed and optimize processes with minimal energy usage. Efficient robots also help lower the carbon footprint, which is vital for environmentally friendly production.

7. Artificial Intelligence (AI) makes robots smarter

Robots equipped with AI can analyze large data sets and make real-time decisions. This means they become better and smarter with every working hour. AI enables robots to identify patterns in production processes and propose optimizations, further increasing efficiency. Additionally, AI-powered robots can predict failures and prevent downtime, ensuring greater reliability and lower maintenance costs.

8. Machine vision capabilities

Industrial robots with “sight” use cameras and sensors to detect colors, patterns, and defects. This makes quality control faster and more efficient. Vision systems also allow robots to perform complex tasks such as positioning products, visual inspection, and automatic error detection. This reduces the need for human oversight and enhances the accuracy of the entire production process.

9. An investment in the future

Using industrial robots demonstrates that your company is keeping pace with modern developments. This boosts your competitiveness and builds trust with your client base. Implementing robots helps businesses adapt quickly to changing market conditions and prepare for a future where automation is the norm. Additionally, adopting robots makes companies more attractive to potential investors and partners.

10. Endless possibilities

The capabilities of industrial robots are continually evolving, with new technological advancements emerging daily. The versatility of industrial robots allows them to be used in various fields, from manufacturing auto parts to assembling electronics. Investing in robots is not just about reducing costs but also unlocking new opportunities that take production efficiency and quality to entirely new levels.

How to use this information to your advantage?

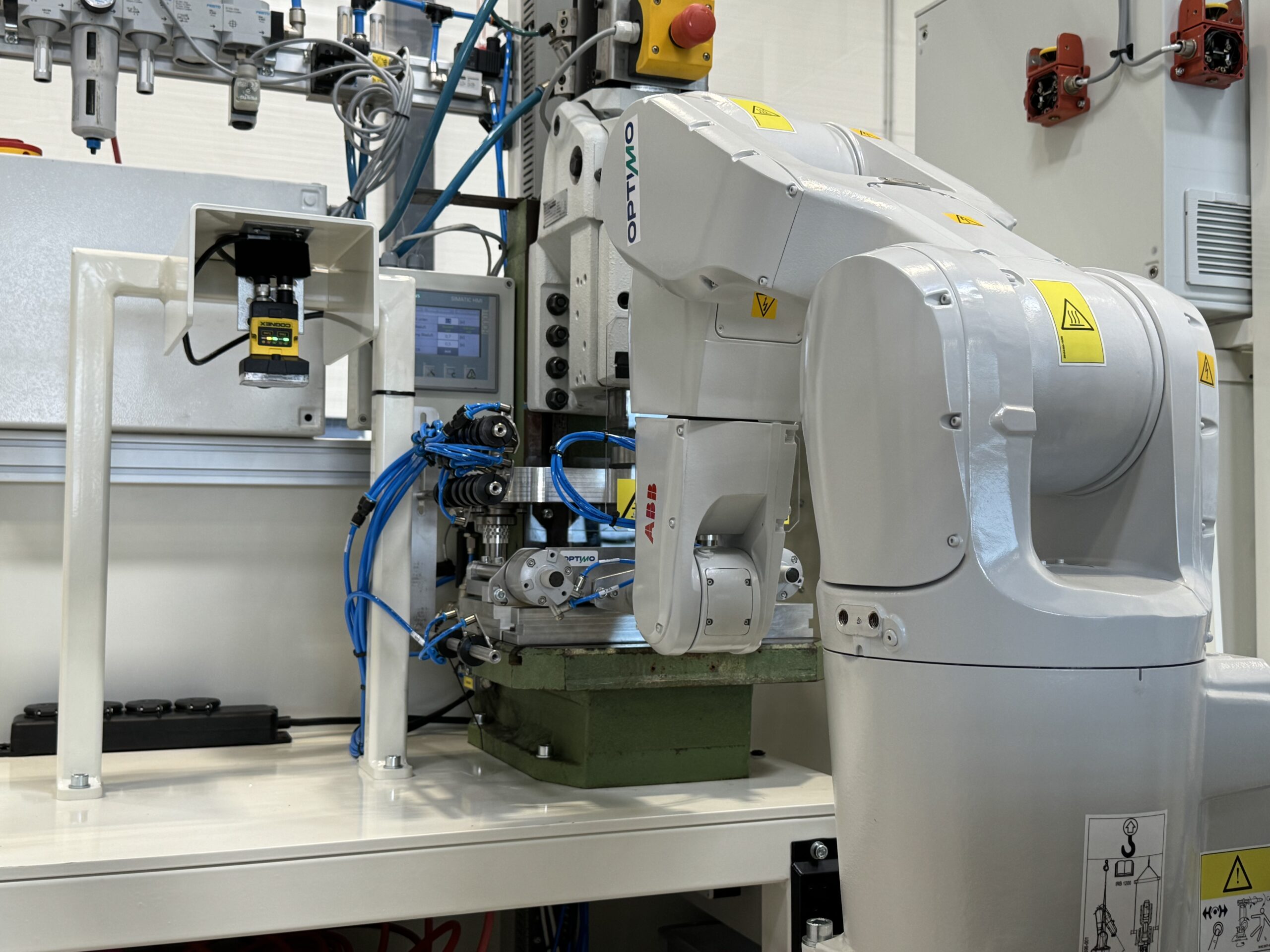

Are you ready to take your production to the next level? Optimo Robotics offers all the solutions you need to start using robots today. Our experts will help you identify and implement the best industrial robot solutions tailored to your needs.

Learn more about our services and contact us here.