Case studies

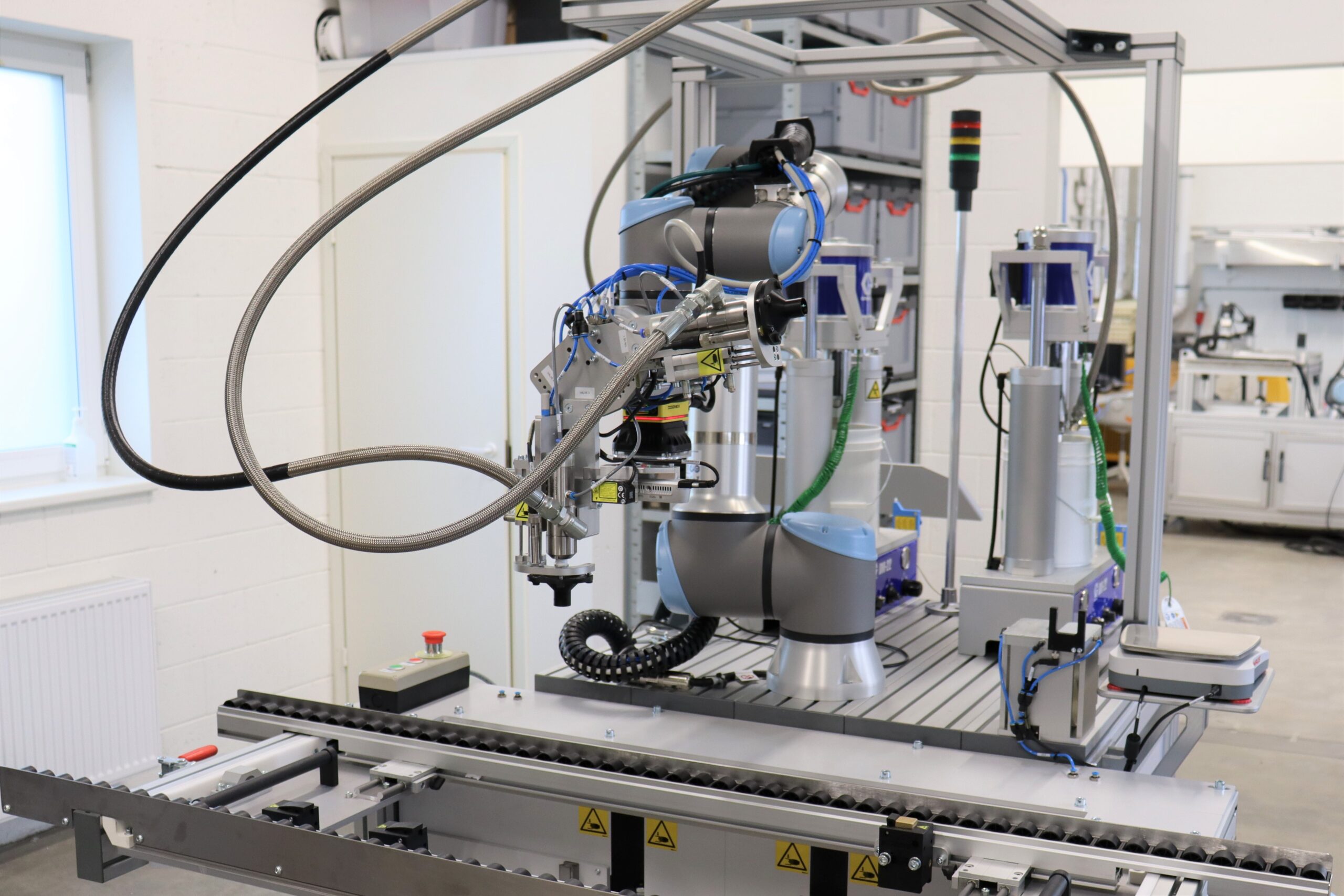

Cobot Screwdriving System

The telecommunications sector, with its complex assembly requirements, posed a unique challenge. The primary task was to develop a robotic screwdriver system that not only meets the specific needs of this industry but also provides the necessary flexibility for high-mix, low-volume production. This equipment needed to comply with global standards, including CE marking, UL compatibility, […]

View case

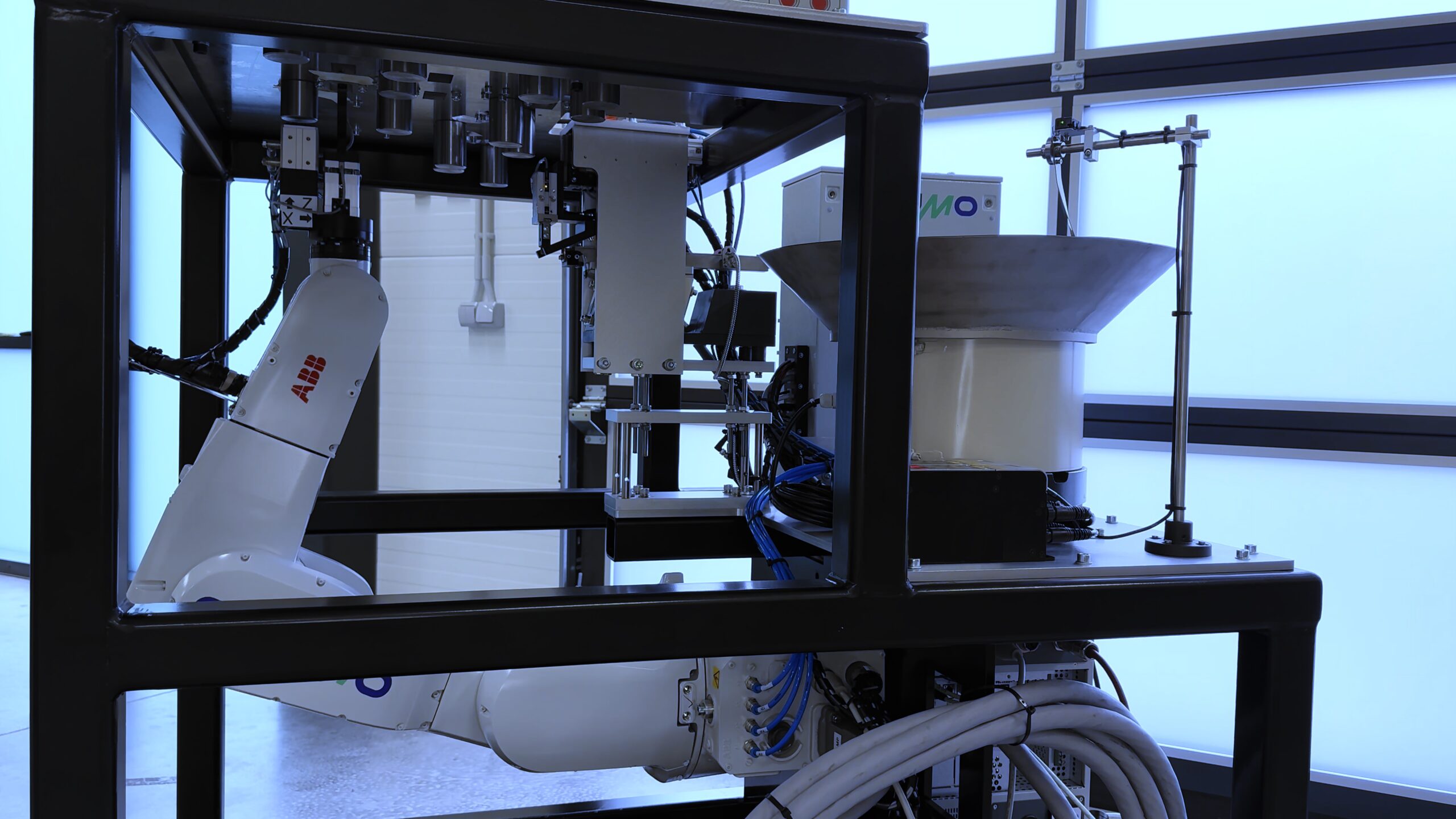

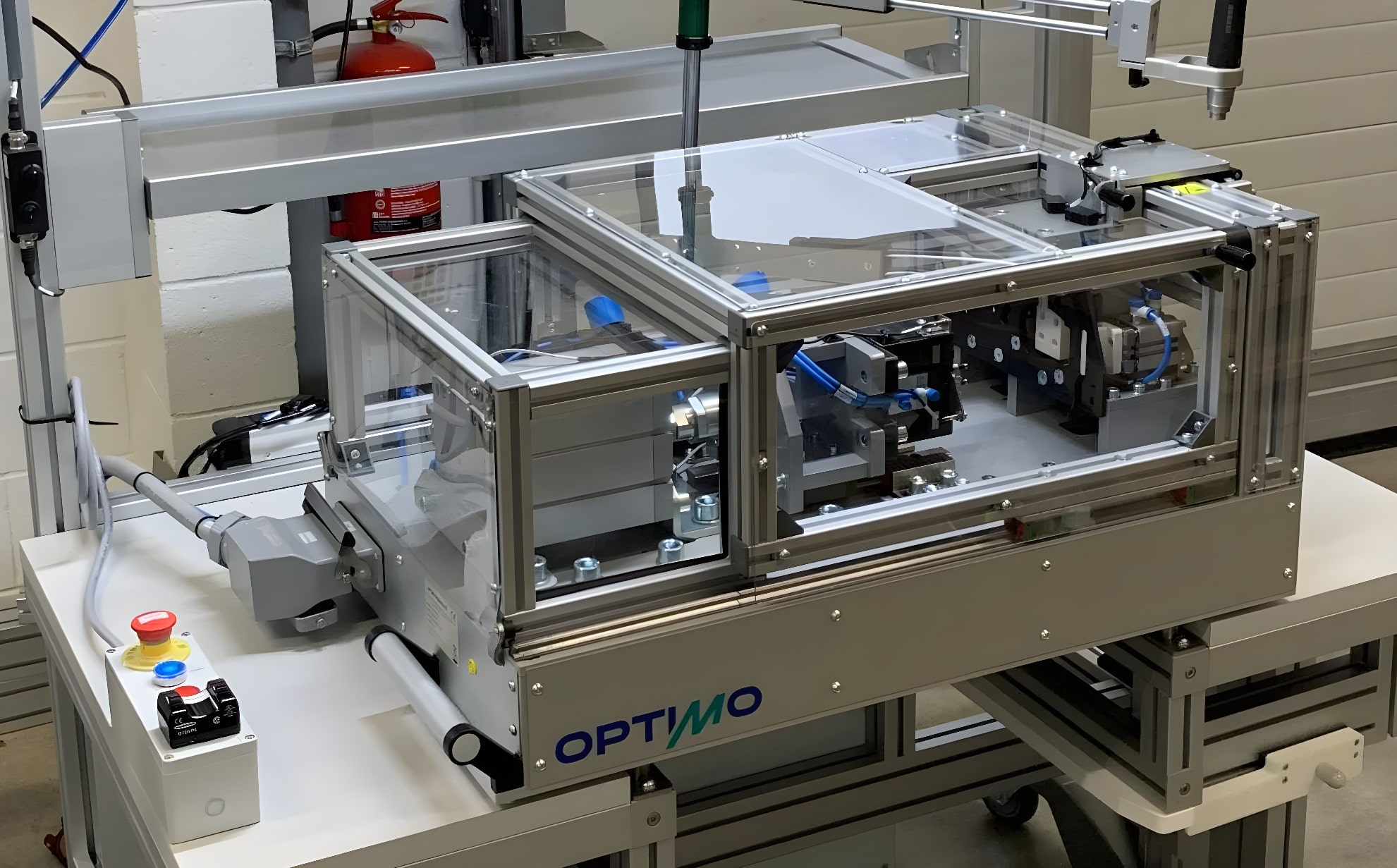

Clips Assembly Robotic System

The goal of this project was to develop a highly efficient and compact robotic system for assembling metal clips into plastic products. The system needed to fit within a limited space of 900 x 1200 x 1150 mm and achieve a rapid assembly cycle time of 3 seconds per clip.

View case

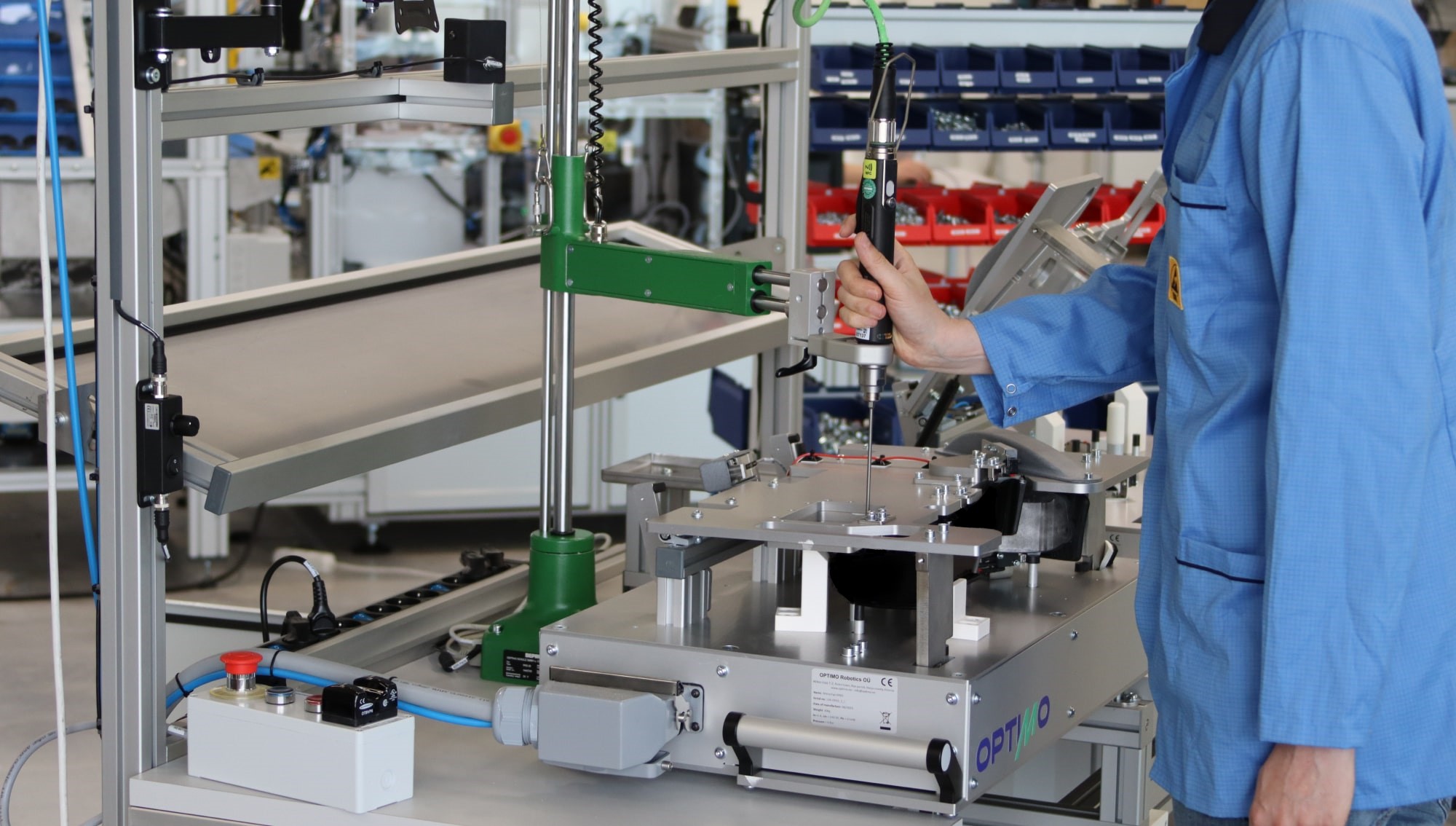

Screw-driving Workstation with Assembly Fixtures

The project involves the development and production of specialized screwdriving and production assembly equipment, designed to facilitate the efficient assembly of plastic covers onto aluminum bodies. Following the assembly process, the parts will be securely fastened together using screws. The equipment includes an electrically height-adjustable workstation, an electrical cabinet equipped with a PLC, custom assembly […]

View case

Thermal Paste Dispensing System

Thermal Paste Dispensing Robots are crucial for telecommunication producers. As telecommunication equipment often involves high-performance electronics that generate heat, maintaining optimal temperatures is essential for performance and longevity. These robots precisely apply thermal paste to components like PCBs, processors, and other heat-generating elements.

View case

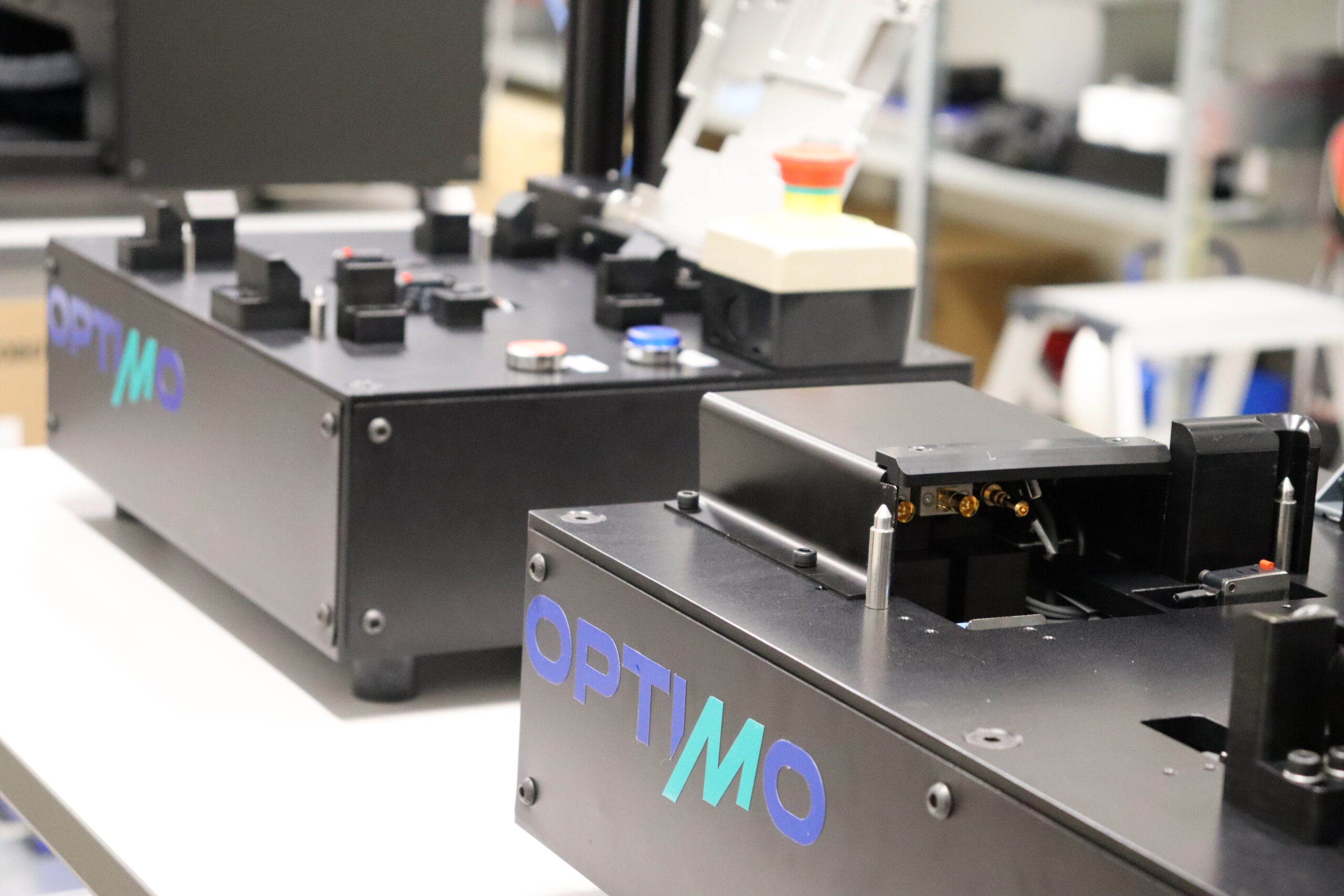

Assembly and Test Fixtures with machine vision

The production of an electronic product required a sequence of detailed assembly operations, each demanding precise product alignments, and fixture-based workflows. The variability in tasks – from SSD insertion and thermal padding to end-of-line labelling – presented a significant challenge that necessitated seamless collaboration between human and machine.

View case

Clips Pressing Fixtures with Workstation

To ensure a seamless integration of both manual and automated operations in the assembly of metal clips to plastic covers, our system guarantees precise part positioning and secure fixation during the process. This approach, all within a single assembly fixture, provides consistent quality assurance and efficiency.

View case

Pressing and Screwing Fixtures with Workstation

This project involves the development and production of specialized production assembly equipment, specifically designed to enable accurate press-fitting and screwing. After the press-fitting process, parts will be securely joined using screws. The equipment features an electrically height-adjustable workstation and an electrical cabinet outfitted with a Siemens S1200 programmable logic controller. Additionally, it includes custom assembly […]

View case

Contact us!

Don't let your business fall behind, stay ahead of the curve with automation! We aim to respond within 24 hours!