Pressing and Screwing Fixtures with Workstation

Project description

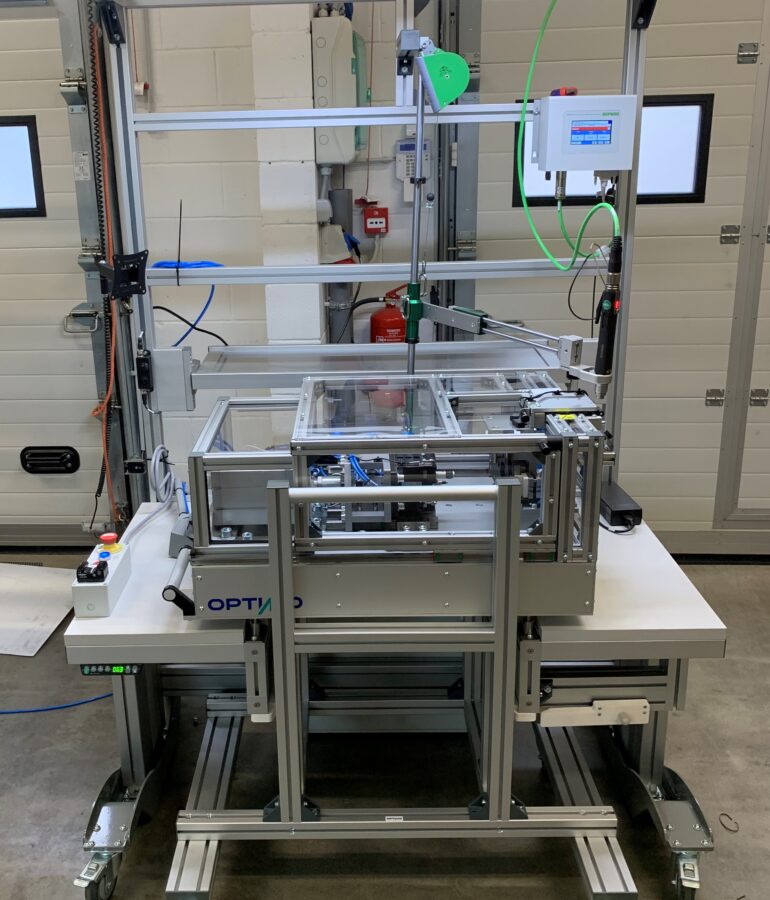

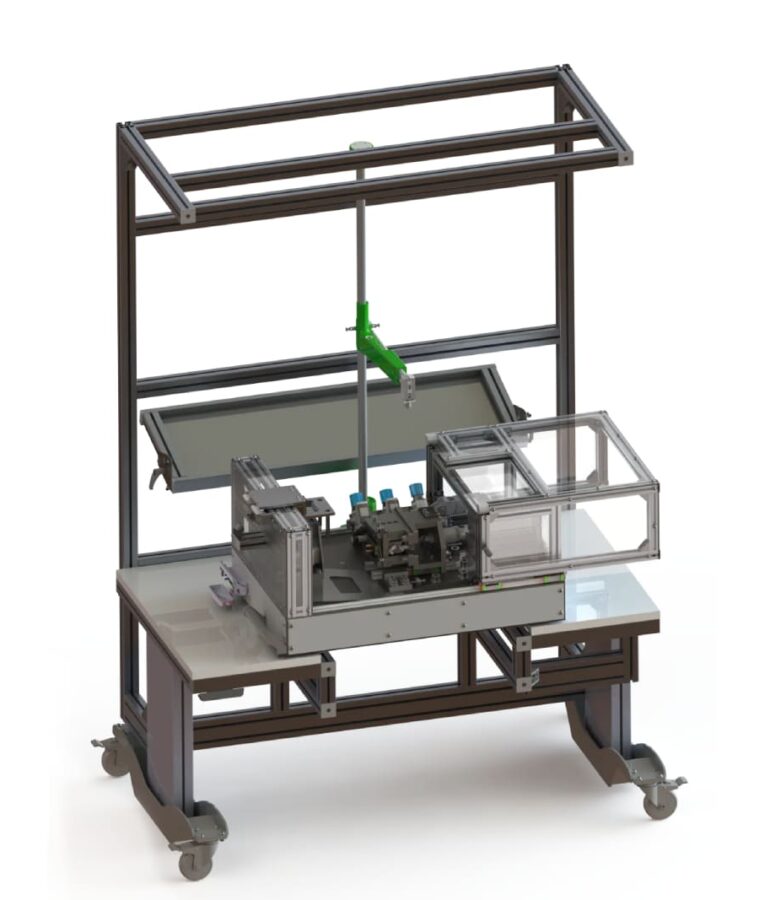

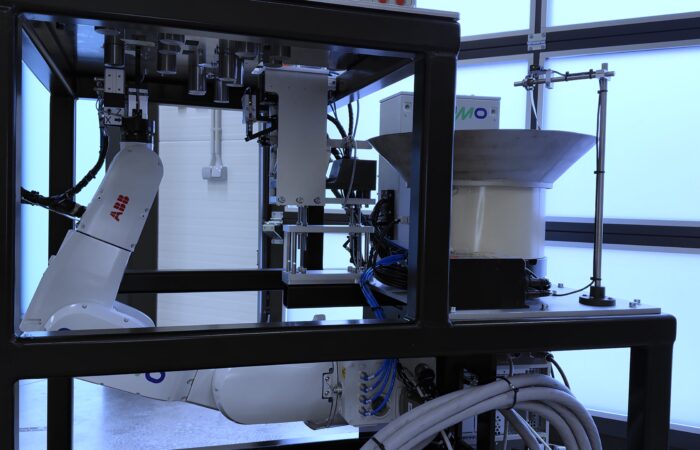

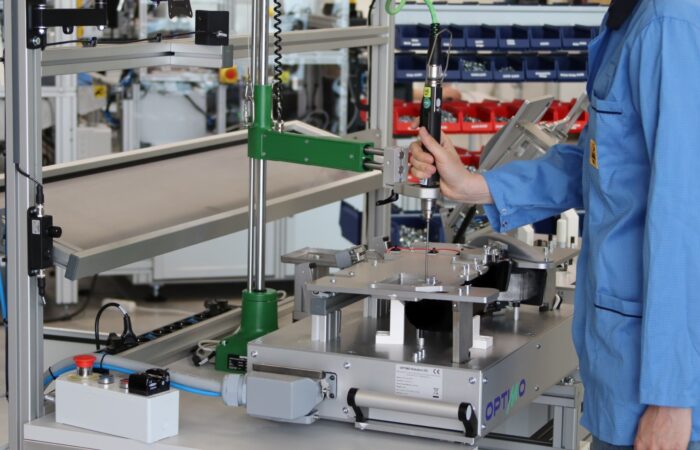

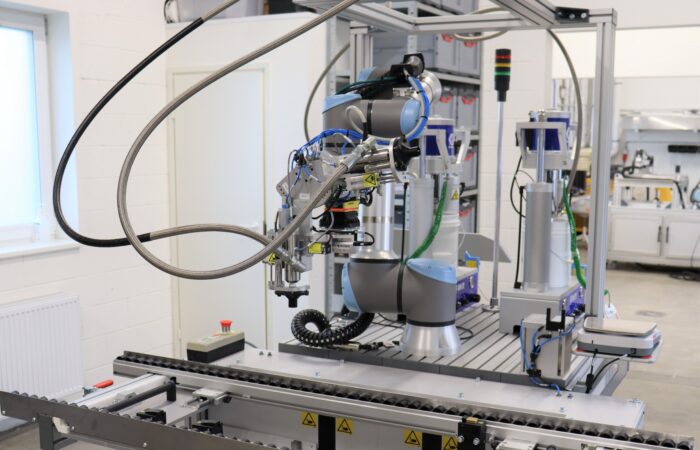

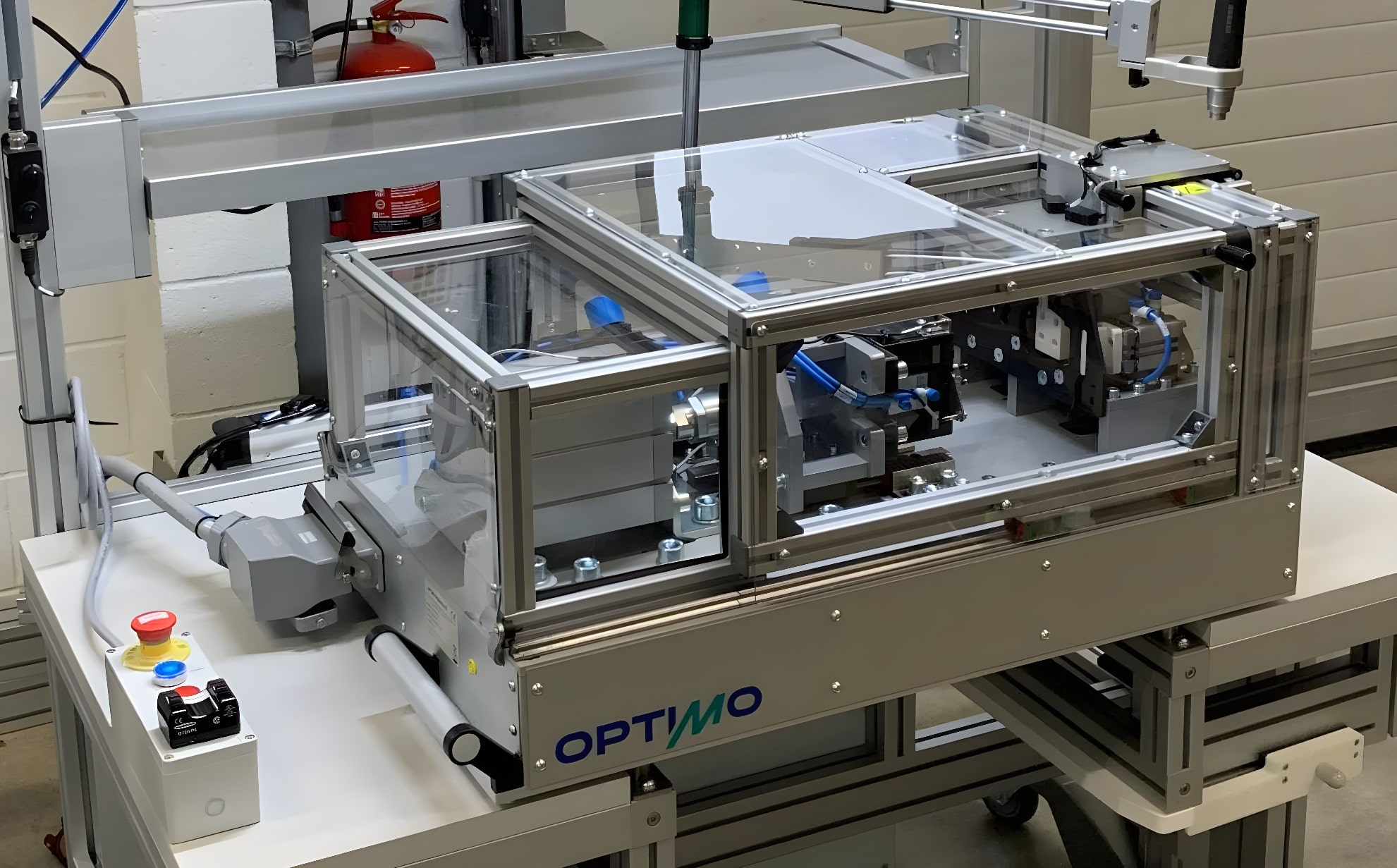

This project involves the development and procurement of specialized production assembly equipment, specifically designed to enable accurate press-fitting and screwing. After the press-fitting process, parts will be securely joined using screws. The equipment features an electrically height-adjustable workstation and an electrical cabinet outfitted with a Siemens S1200 programmable logic controller. Additionally, it includes custom assembly fixtures and is integrated with a screwdriver system for comprehensive functionality.

Solution

- Assembly Fixtures with press

- Controlled assembly sequence

- Trolleys for fixture changeover

- Workstation with electrical height adjustment

Industry

Automotive, electronics

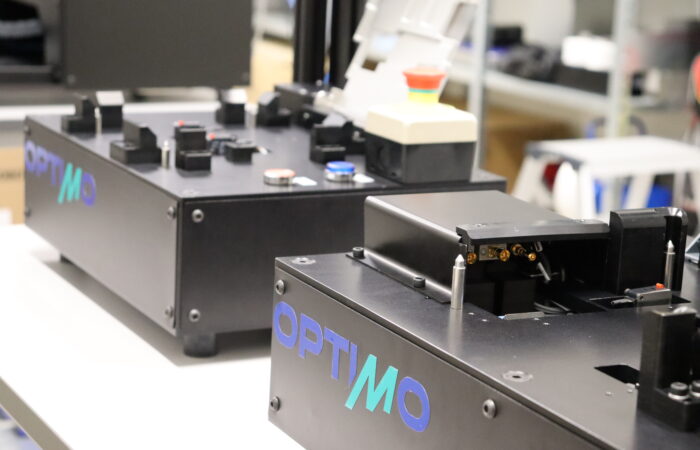

Products used

- ESD Workstation

- Moblile product trolleys

Services

- Engineering (mechanical, electrical, pneumatics)

- Programming

- Machine building

- Installation

The challenge

The solution

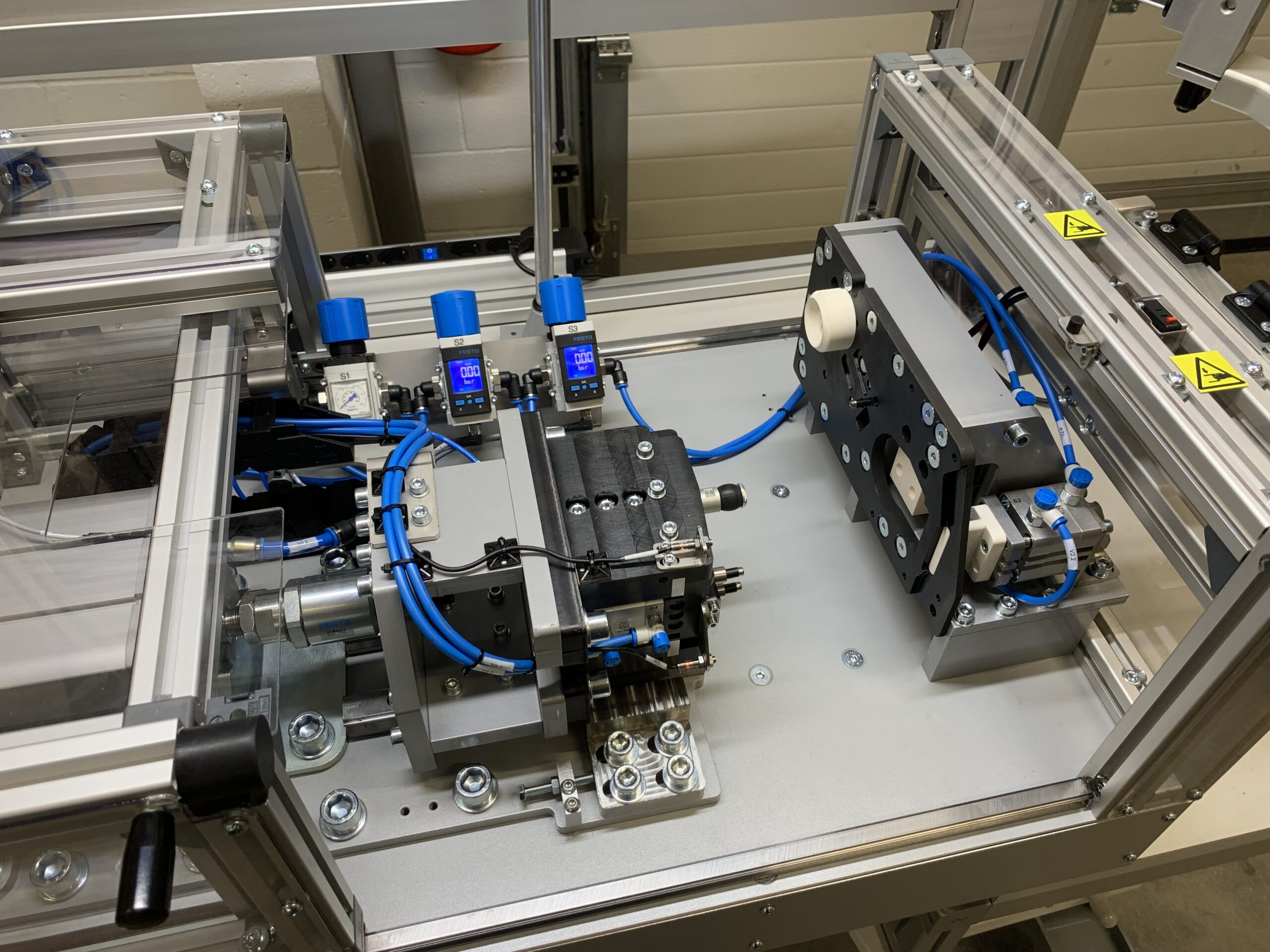

Pressing and Screwing Workstation

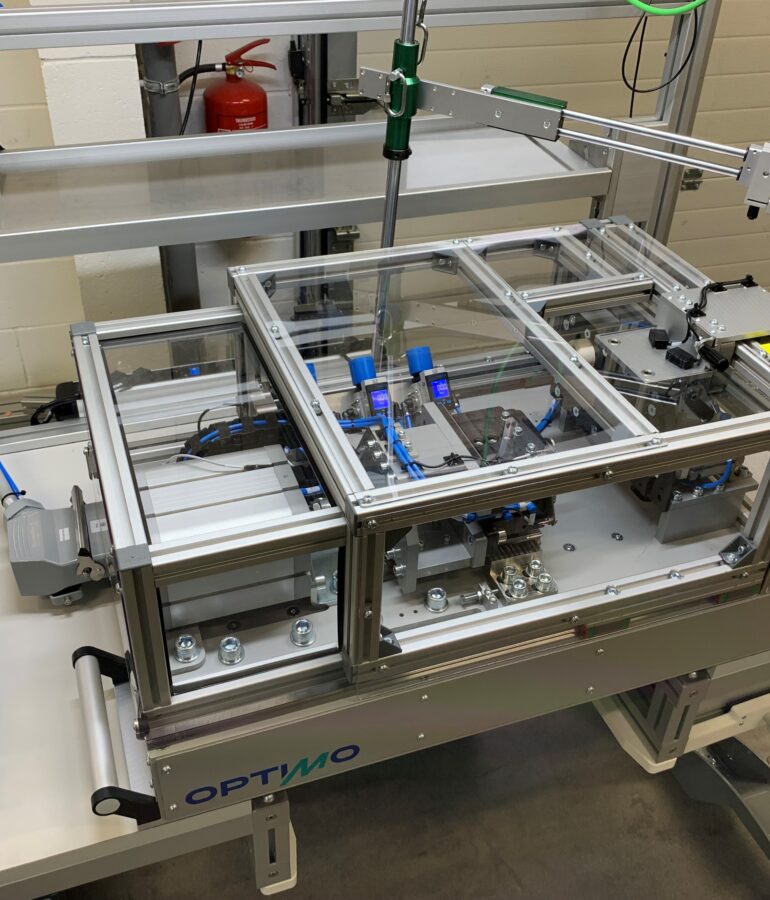

Incorporating advanced detection systems, the pressing fixture verifies the presence and positioning of each part, ensuring perfect alignment and proper orientation. Its integrated scanning capabilities make every unit traceable, allowing for accurate variant detection. The pneumatic press provides a uniform press fit, complemented by a screwing system equipped with electronic torque control and angle monitoring, ensuring secure and precise fastening.

The summary

Contact us!

Don't let your business fall behind, stay ahead of the curve with automation! We aim to respond within 24 hours!