Clips Pressing Fixtures with Workstation

Project description

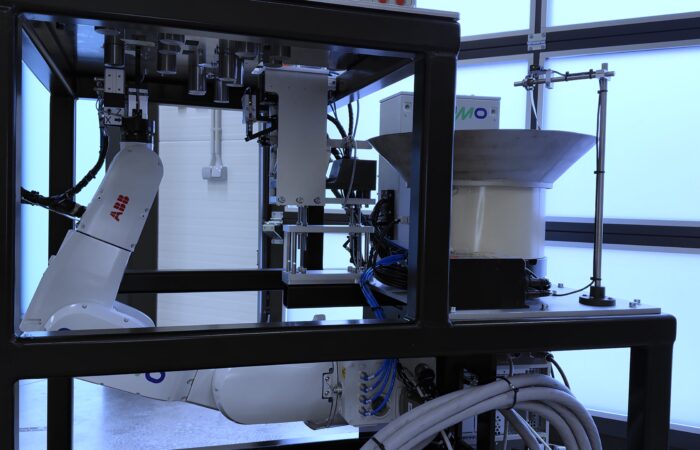

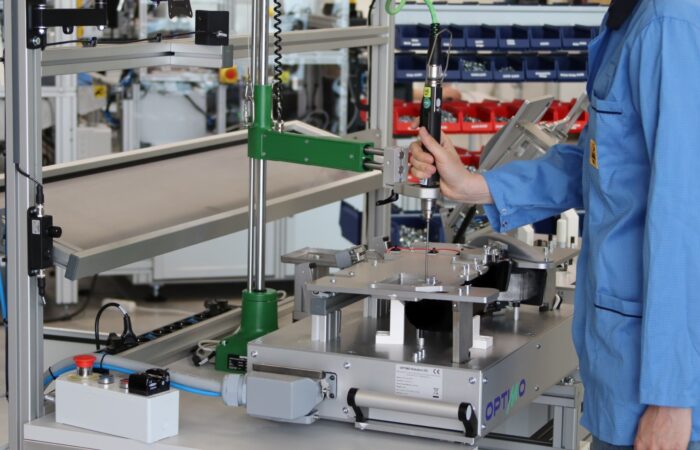

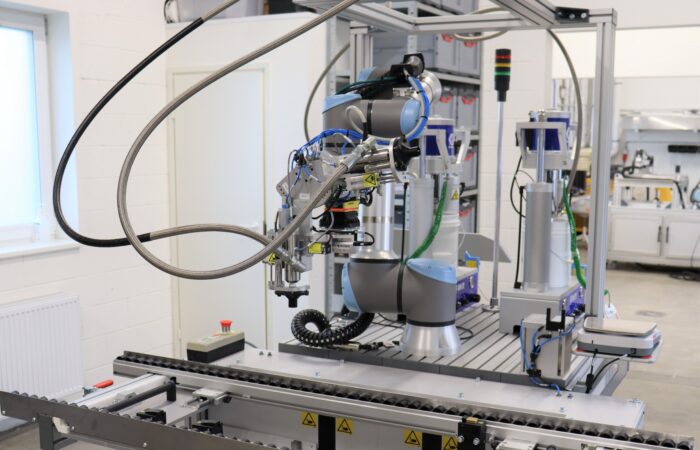

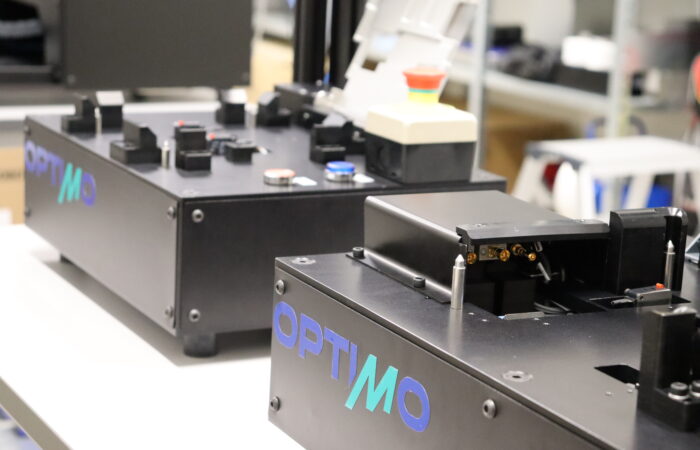

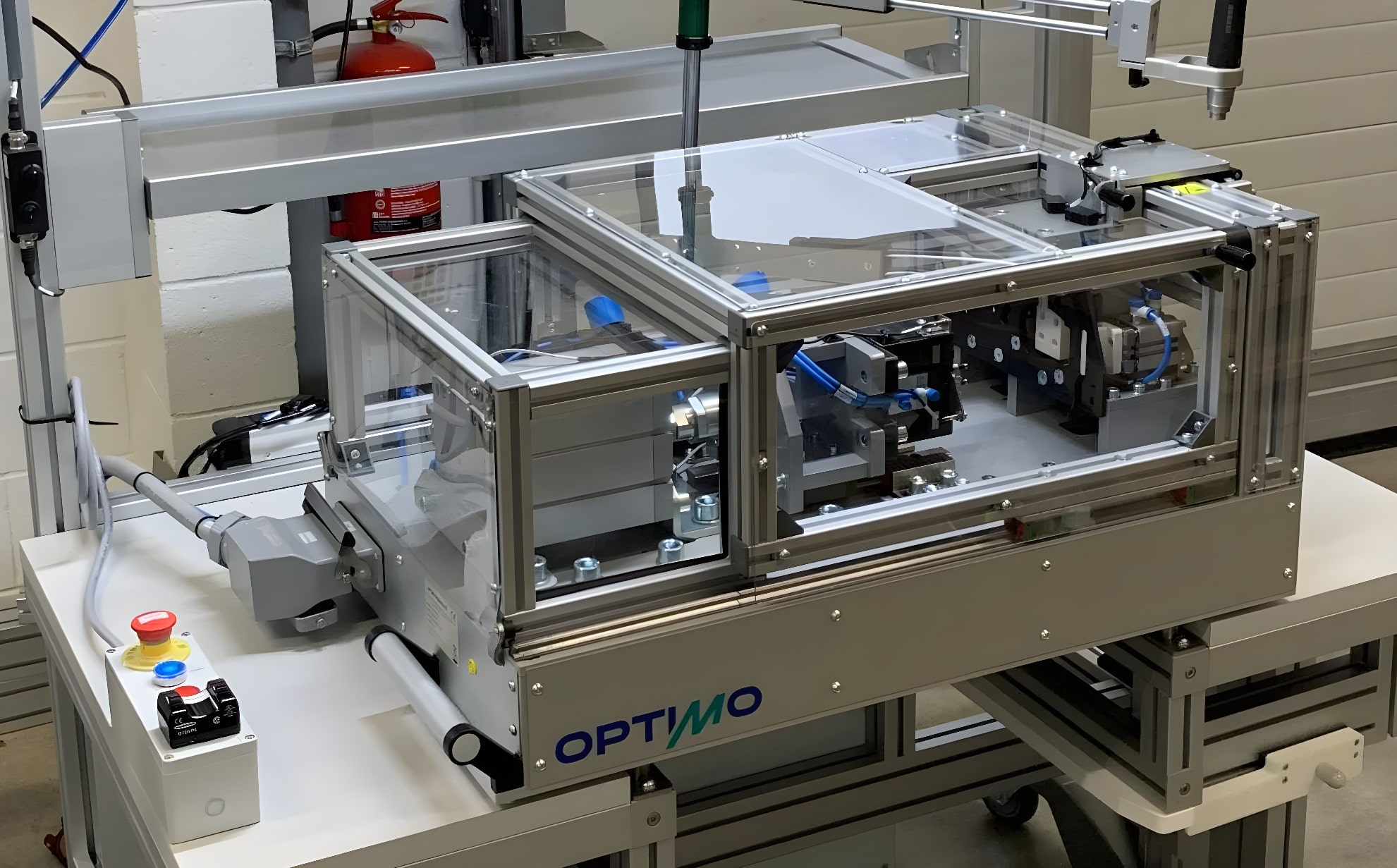

The project involves the development and production of specialized production assembly equipment, designed to facilitate the efficient assembly of metal clips to plastic covers. Following this assembly process, the parts are securely fastened through pressing. The equipment includes an electrically height-adjustable workstation, an electrical cabinet equipped with a Siemens S1200 programmable logic controller, and custom assembly fixtures.

Solution

- Assembly Fixtures with presses

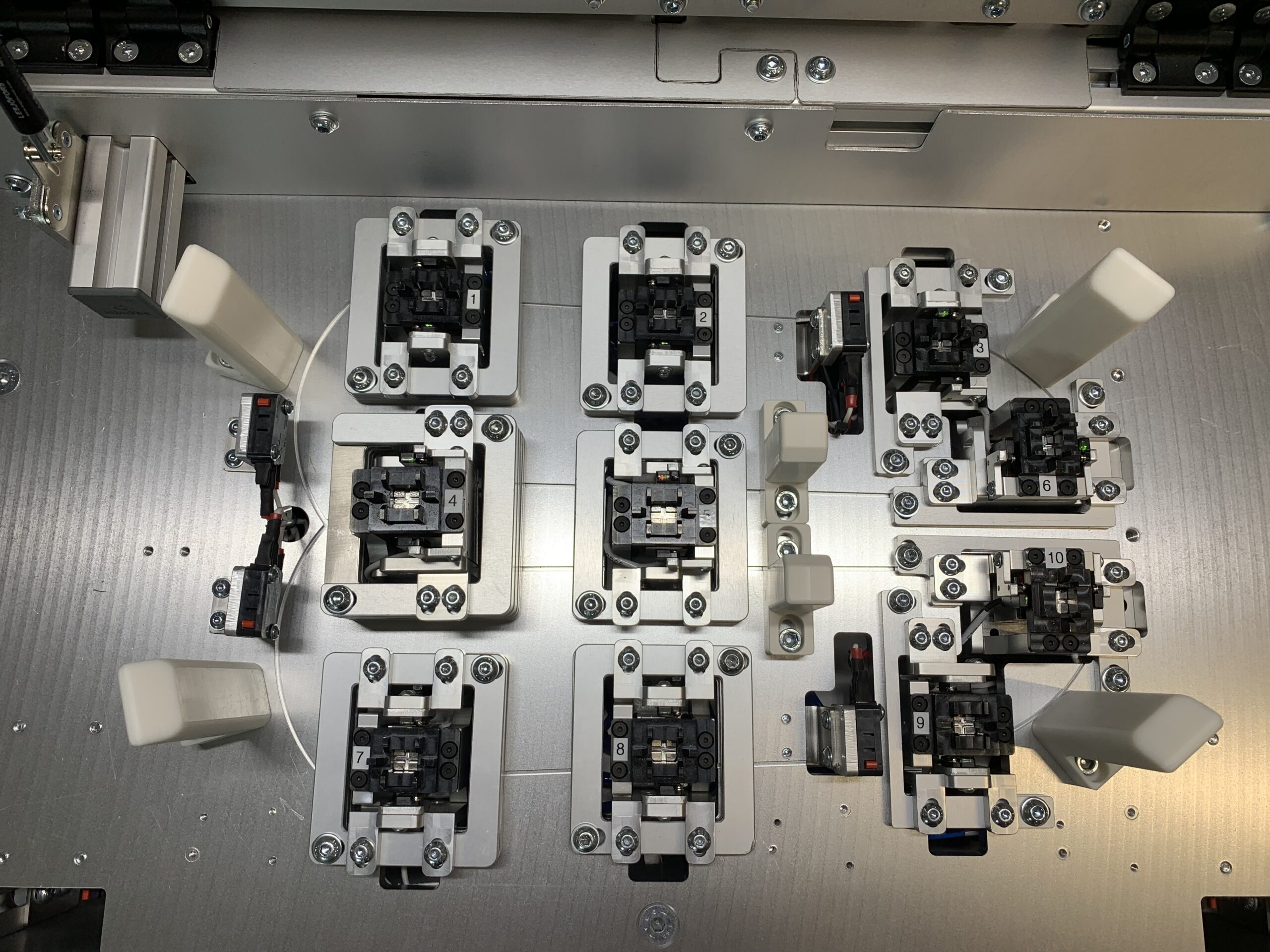

- Controlled assembly sequence

- Trolleys for fixture changeover

- Workstation electrical height adjustment

Industry

-Automotive, elecronics

Products used

- ESD Workstation

- Moblile product trolleys

Services

- Engineering (mechanical, electrical, pneumatics)

- Programming

- Machine building

- Installation

The challenge

The solution

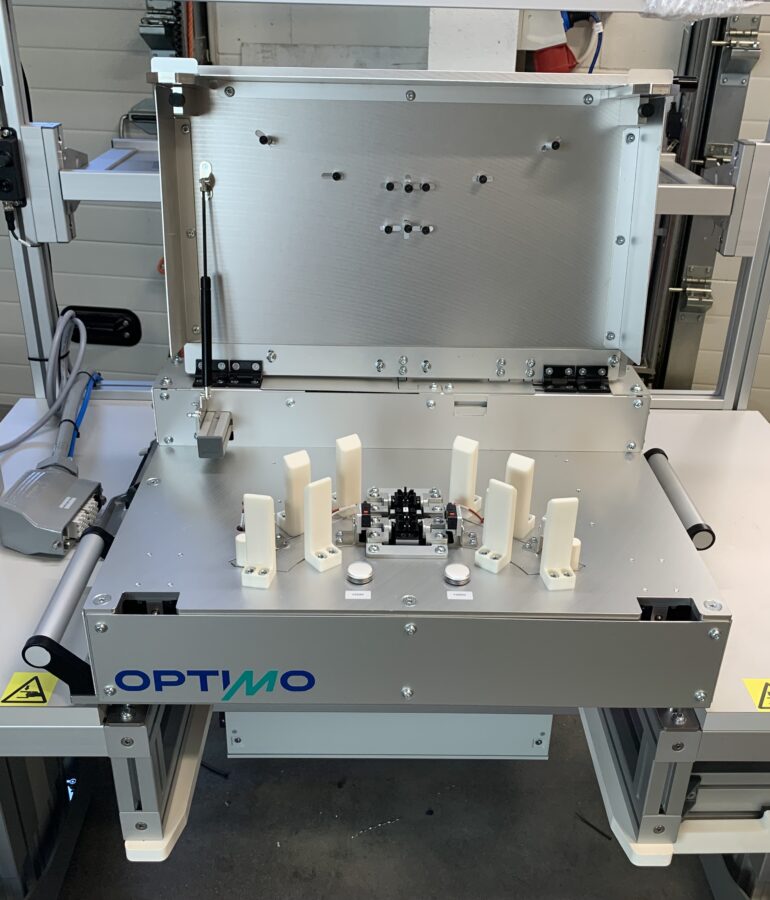

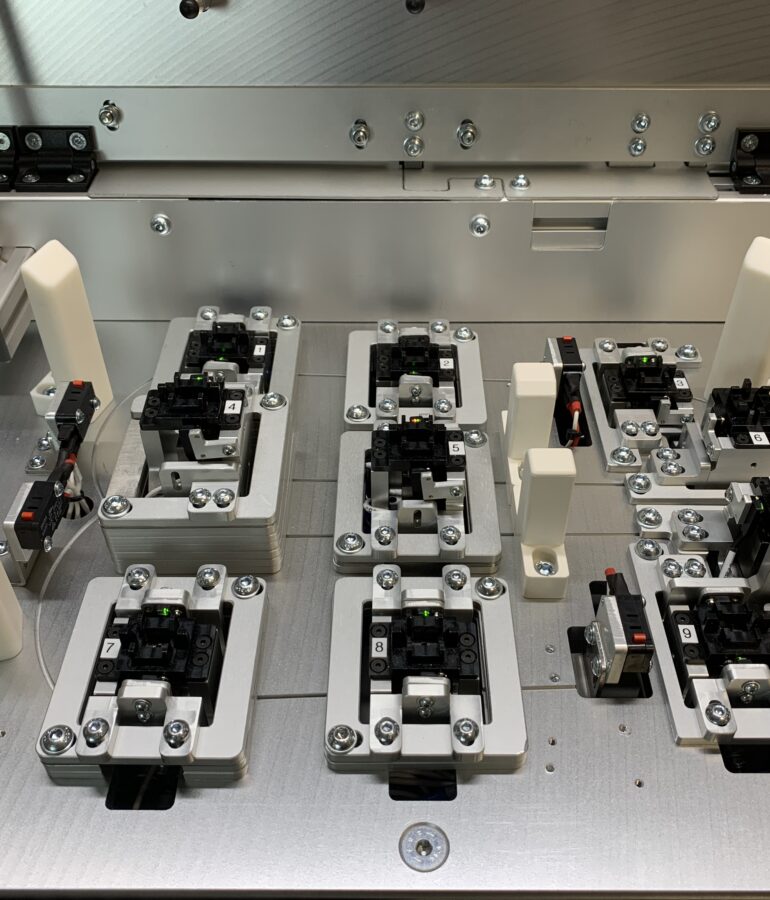

Clips Assembly Fixture for Plastic Parts

The Clips Assembly Fixture has been developed to control a sequential workflow in assembly process, combining part presence and position detection, automated mask locking, and pneumatic presses for clip attachment. Manual operations, including label placement and scanning, are efficiently incorporated to ensure product traceability and quality assurance.

The summary

Contact us!

Don't let your business fall behind, stay ahead of the curve with automation! We aim to respond within 24 hours!