Clips Assembly Robotic System

Clips Assembly Robotic System

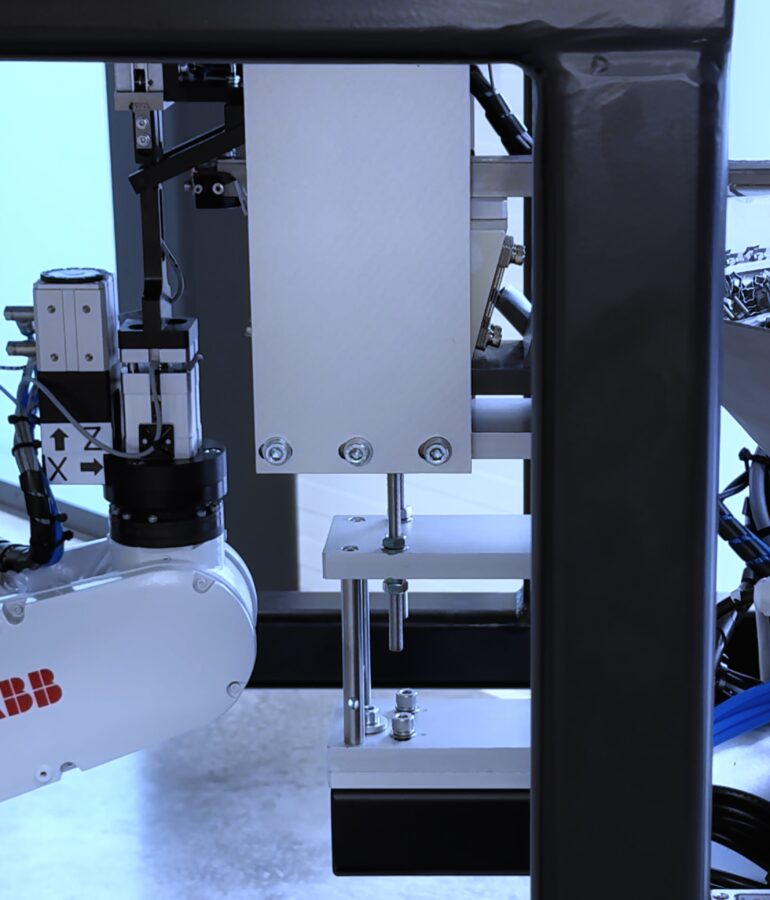

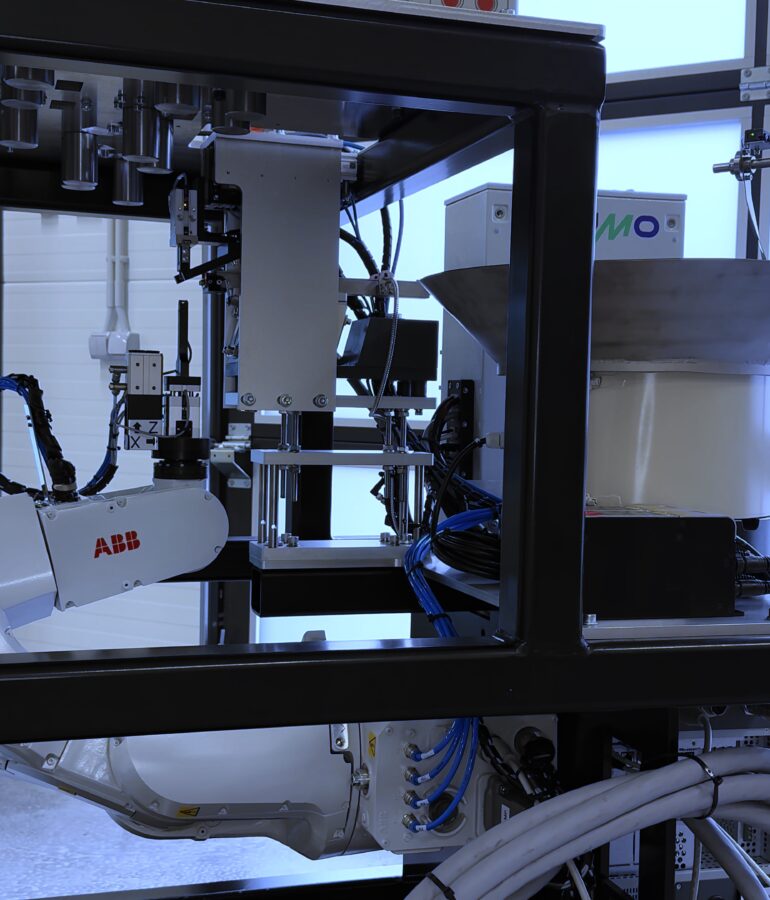

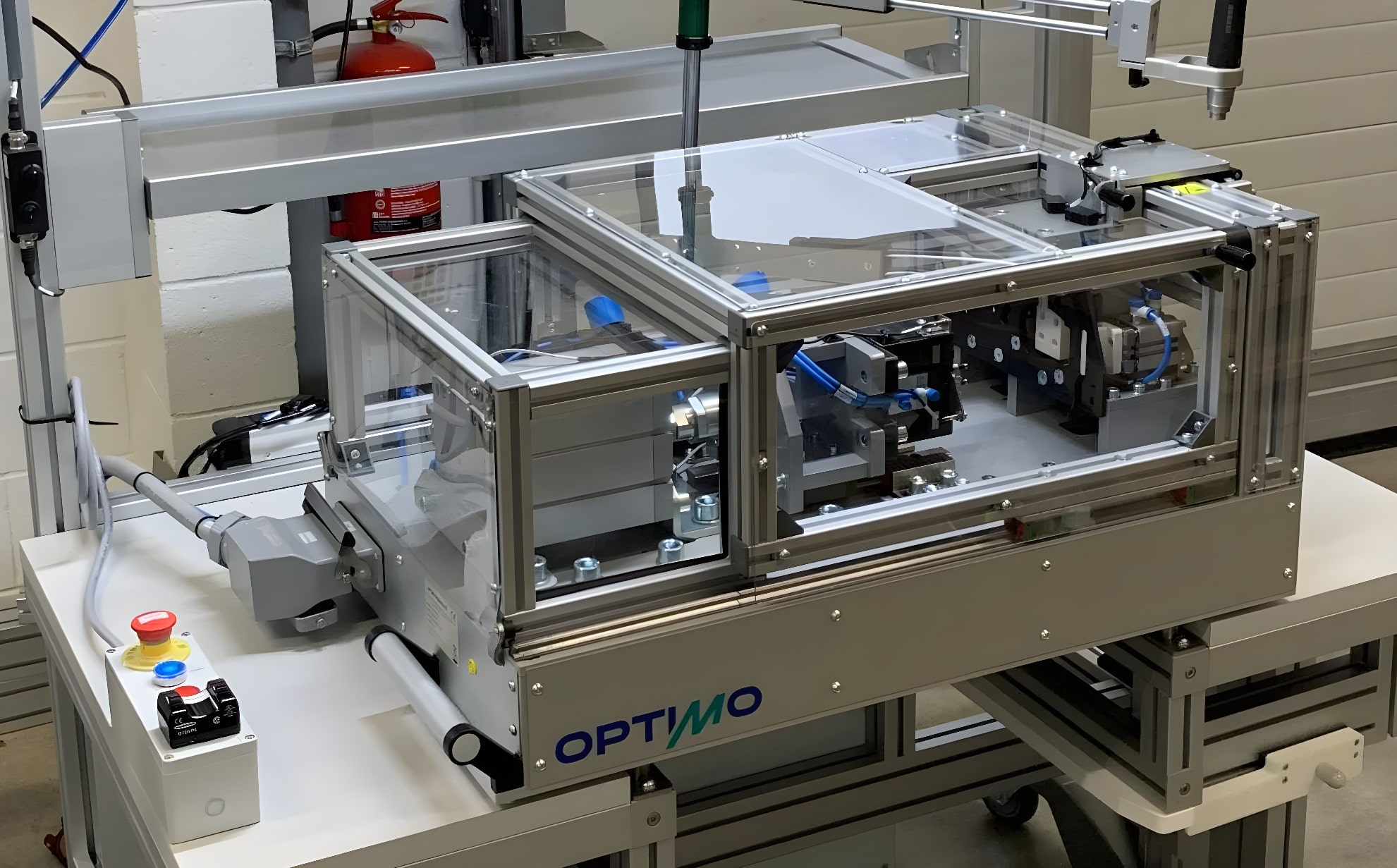

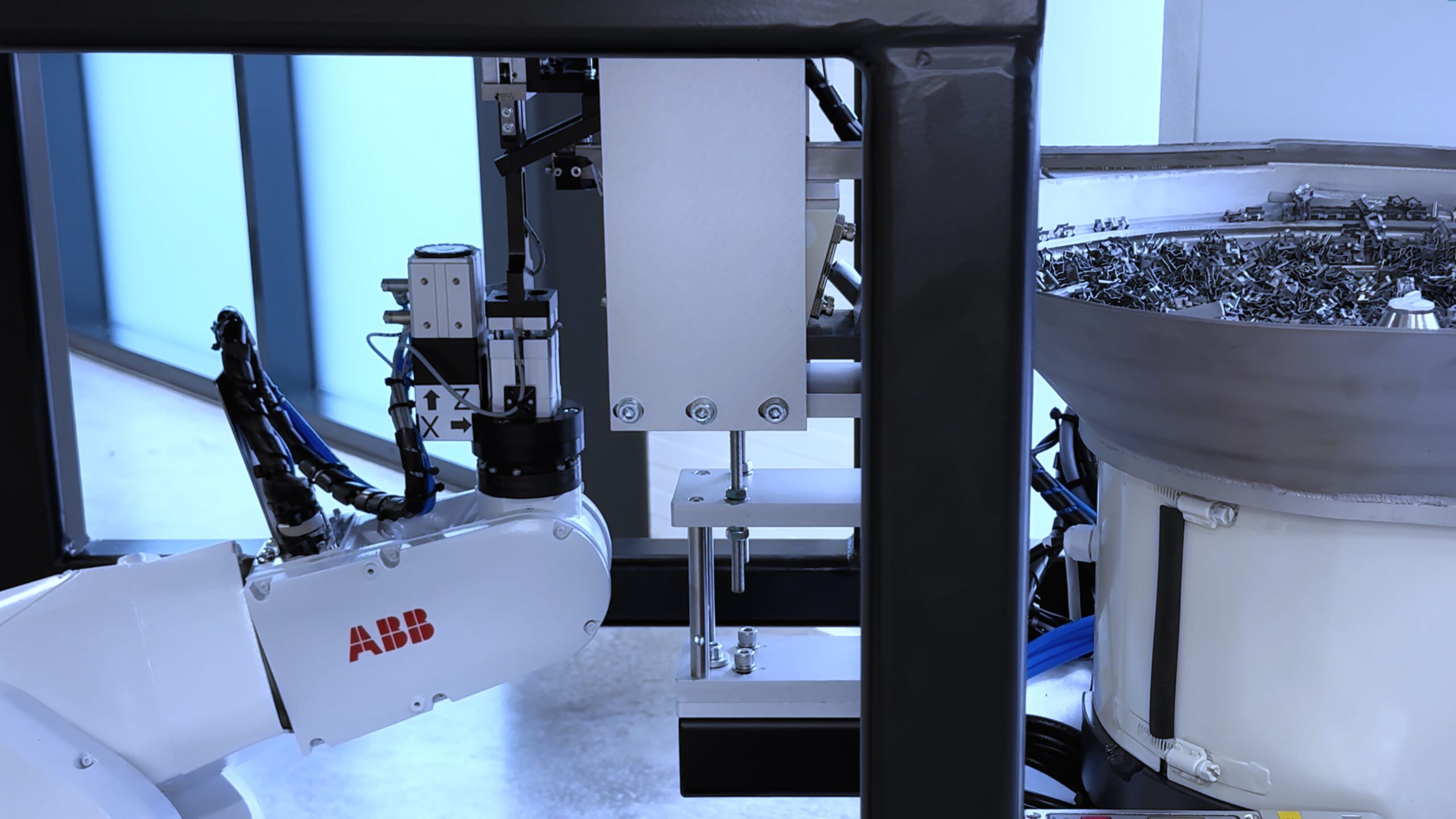

The goal of this project was to develop a highly efficient and compact robotic system for assembling metal clips into plastic products. The system needed to fit within a limited space of 900 x 1200 x 1150 mm and achieve a rapid assembly cycle time of 3 seconds per clip.

Solution

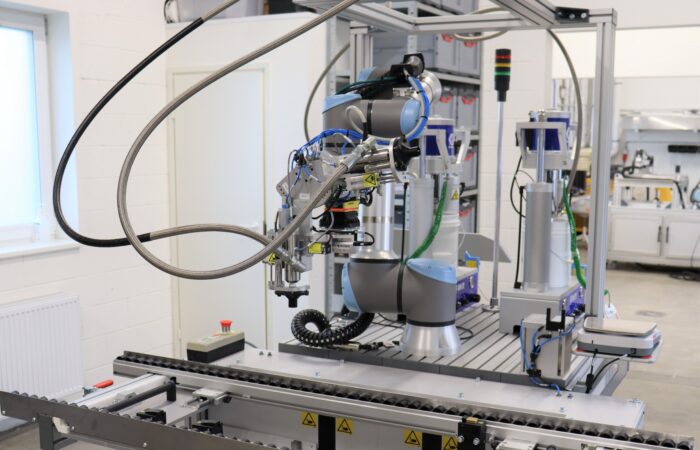

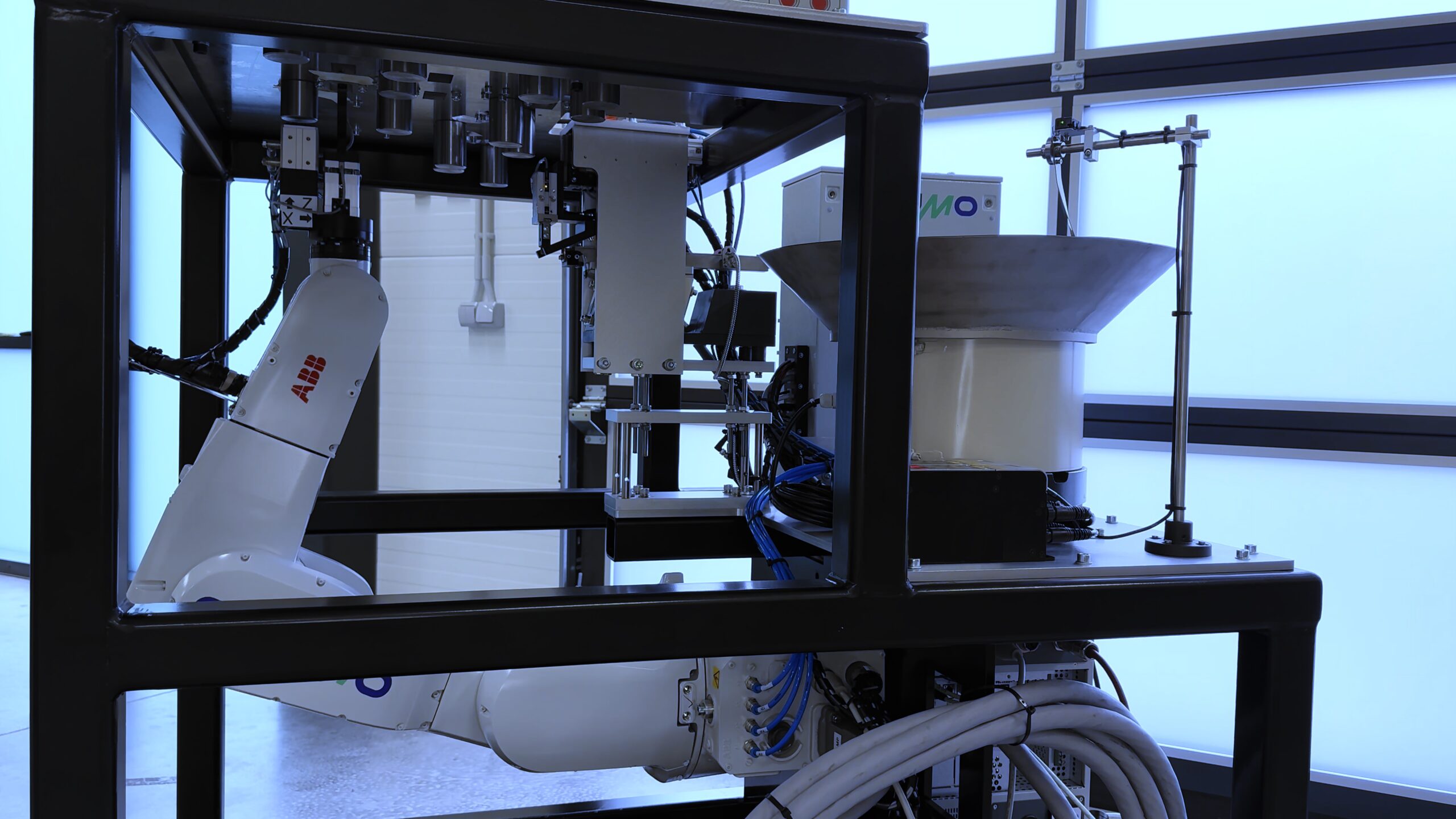

- ABB IRB 1200 for clips assembly

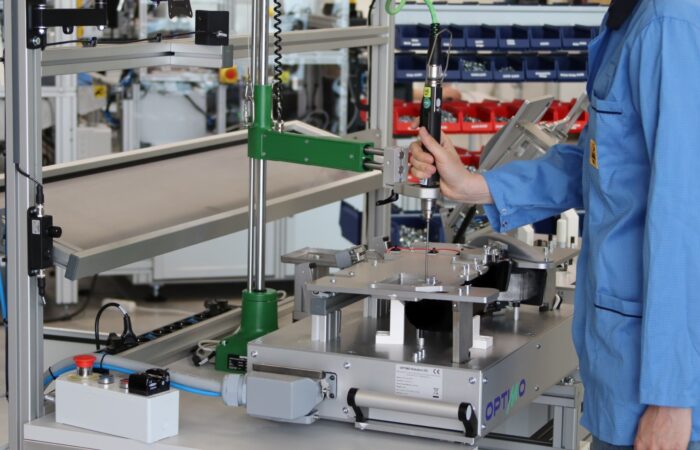

- Top fixture for product fixation

- Welded frame

- 4 different products, 2 product groups

Industry

- Automaotive & Plastics industry

Products used

- ABB IRB 1200

- Bowl feeder for metal clips

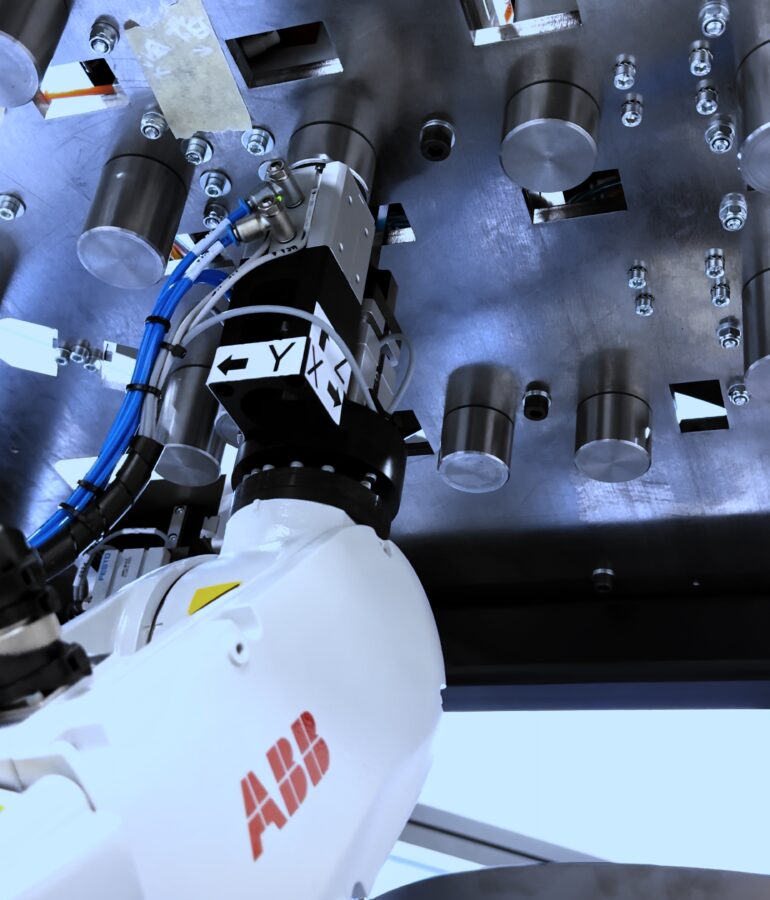

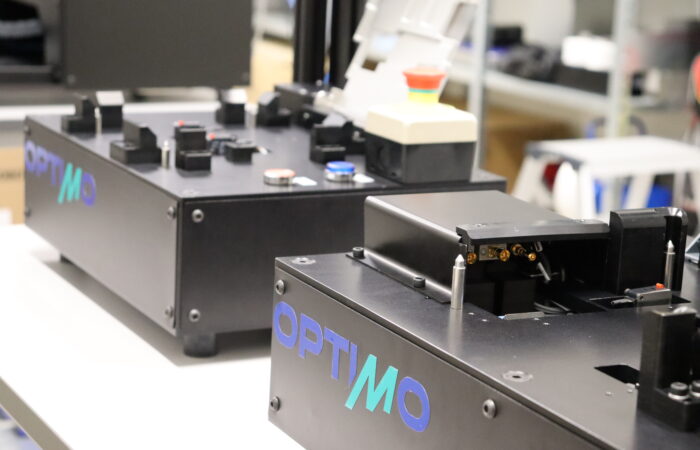

- Magnetic Gripper (End of Arm Tooling - EOAT)

- Clips holder and pusher

- Siemens PLC and Electrical Cabinet

Services

- Engineering (mechanical, electrical, pneumatics)

- Programming

- Machine building

- Installation

The challenge

The solution

Integrating Compact Design with High-Speed Robotics

A robust solution was implemented using the ABB IRB 1200 robot. This robot was selected for its compact size and suitability for high-precision tasks. The system involves a process where the robot retrieves metal clips from a feeder, positions them accurately, and then, using a magnetic gripper, secures them onto a fixture plate. A pusher then integrates the clips into plastic parts. To maximize space and efficiency within the limited footprint, the robot was side-mounted. This orientation was critical in achieving the short cycle time required.

The summary

The Clips Assembly Robotic System successfully met all operational goals

The Clips Assembly Robotic System exemplifies innovative engineering in tackling specific challenges of space constraints and cycle time. This case study demonstrates how strategic component selection and system layout can lead to substantial improvements in manufacturing processes, paving the way for future advancements in automated assembly systems.Contact us!

Don't let your business fall behind, stay ahead of the curve with automation! We aim to respond within 24 hours!