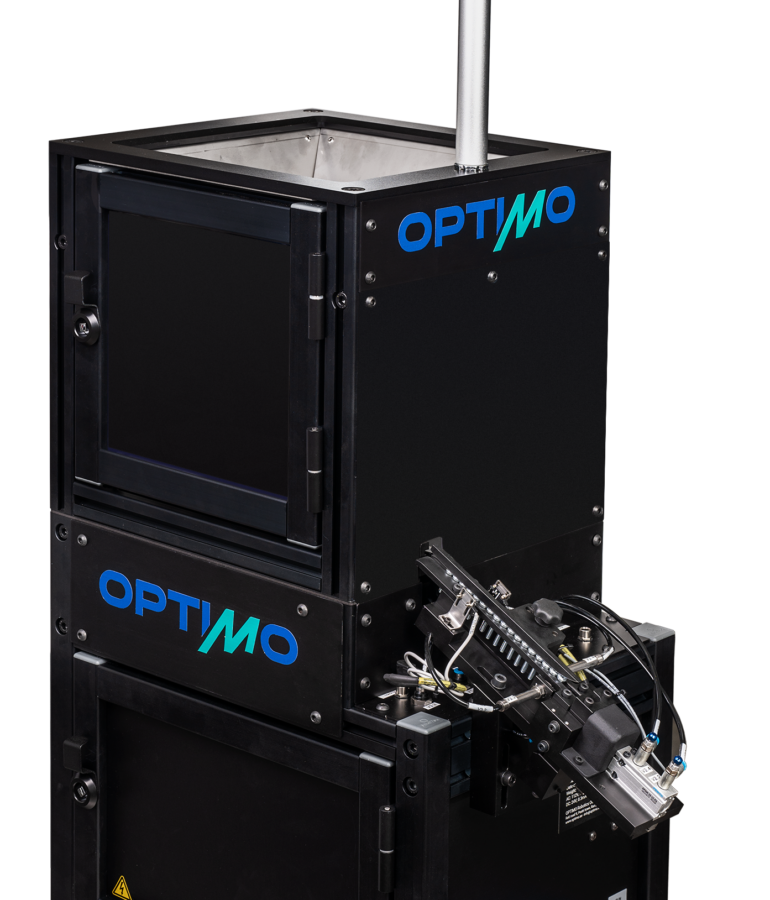

Optimo Screw Feeders: maximize productivity with high-speed feeding!

Silent Efficiency

Low-noise step feeder for screws

Take your production to the next level with the high-speed screw feeders from Optimo Robotics, delivering up to 100 screws per minute for continuous efficiency. These feeders are crafted to fit perfectly together with S1/S2 Screwdrivers or into your current assembly line, representing the ultimate in precision engineering and intelligent automation.

100

Screws / min

Technical specification

Discover the Core Strengths of Our Advanced Pneumatic Screw Feeder.

Pneumatic Air Screw Feeding

Our feeder delivers screws efficiently using pneumatic air, ensuring a smooth and reliable supply to the screwdriver.

Seamless Integration with Robotics

Our feeders, designed for seamless integration with robotic systems, enhance automated assembly lines.

Compact Design

The compact design of our feeders makes them space-efficient, fitting easily into various workshop layouts.

Versatility in Fastener Compatibility

It is adeptly configured to handle different types of fasteners, making it a versatile choice for diverse assembly needs.

Quiet Operation

The low noise feature of our feeder ensures a more pleasant and less disruptive working environment.

Expandable Capacity for Growing Needs

The feeder's capacity can be expanded, allowing for flexibility and scalability in response to increasing production demands.

Power Efficiency

Operating at 220/50Hz, the feeder is designed for energy efficiency without compromising on performance.

Solid Build, Manageable Weight

With a weight of 30kg, the feeder combines robustness with manageability, suited for various industrial environments.

Contact us!

Don't let your business fall behind, stay ahead of the curve with automation! We aim to respond within 24 hours!