Robotic screwdrivers

Get the job done more quickly and accurately, all while reducing the risk of injury or strain. Upgrade your screwing game with a reliable and efficient robot screwdriver today!

Get the job done more quickly and accurately, all while reducing the risk of injury or strain. Upgrade your screwing game with a reliable and efficient robot screwdriver today!

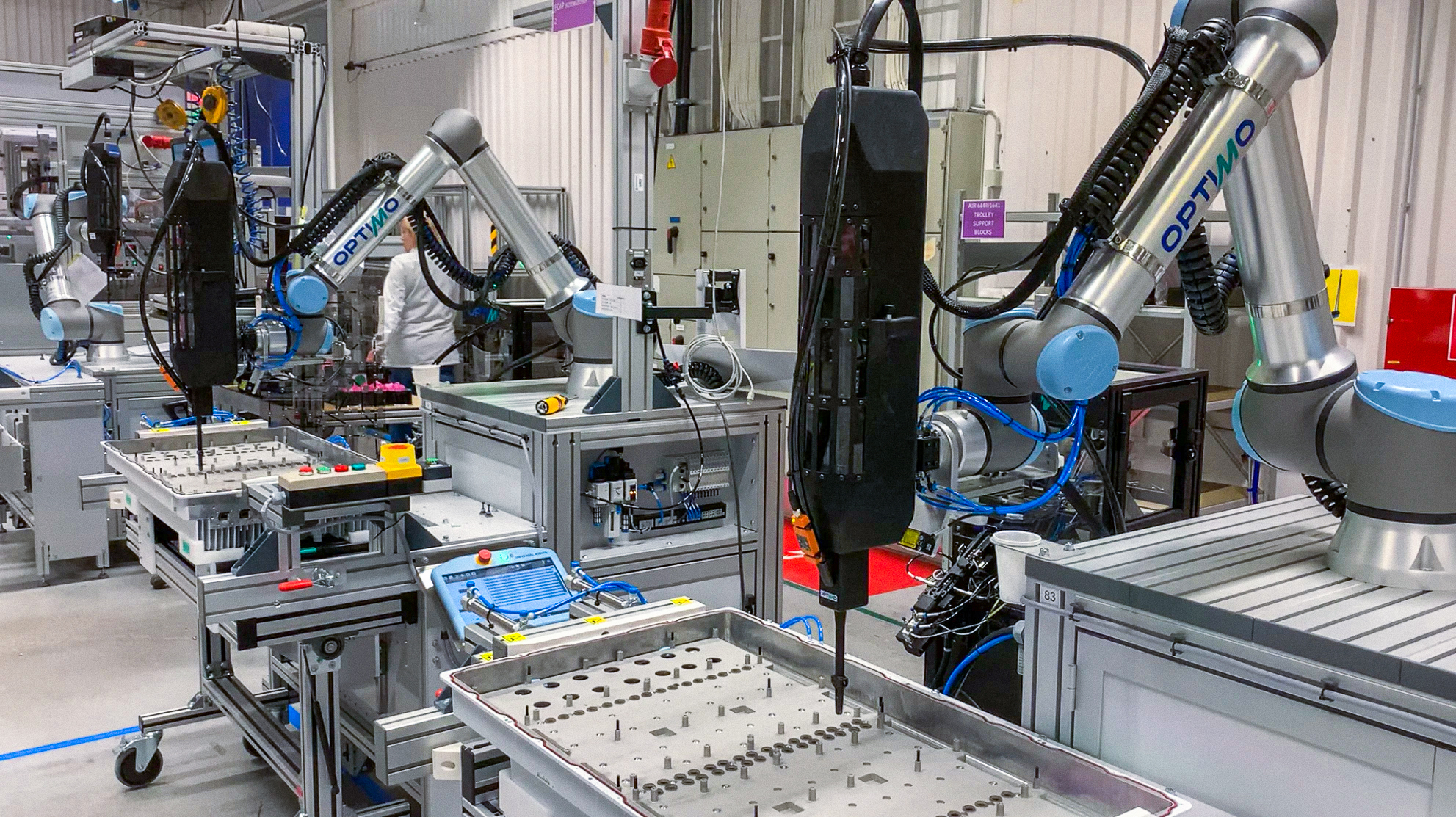

"Transform your production with OPTIMO Robotics Screwdriving system, experience rapid staff training, broad industrial applicability, unparalleled safety in human-robot collaboration, and a significant surge in operational efficiency."

The intuitive graphical user interface eliminates the need for prior robotics or programming experience, reducing training time by up to 90%. The precise control over screwing speeds and torque also results in an estimated 30% improvement in product quality and consistency.

Designed for a wide array of manufacturing industries, the OPTIMO Robotics screwdriving system offers fastening, re-tightening and un-tightening. Its compact tool tip assembly allows it to function in tight spaces, expanding its usability to over 100 different industry settings.

The integrated safety solution in the screwdriver tool tip assembly allows for a fully collaborative approach, offering a 99.9% safe working environment. This enables human workers and robotic systems to work together seamlessly, improving overall productivity by up to 50%.

Thanks to its automatic feeding and a maximum spindle speed of 5000 p/min, the OPTIMO Robotics screwdriving system can increase production speed by up to 70%. The pneumatic air feeding of screws ensures a consistent and rapid supply, further enhancing the efficiency of the system.

"Unleash Precision and Efficiency: Introducing the OPTIMO Robotics S1 and S2 Screwdriver Systems."

The OPTIMO Robotics S1 Screwdriving System is an advanced, high-precision tool designed for stable screw fastening. The patented operating principle and screwdriving method, is the optimal choice for industries such as electronics, telecommunications, and automotive.

View product

The S2 Mini Screwdriver from OPTIMO Robotics features a pneumatic Z-axis for tool movement and a servo motor for accurate tool rotation. This combination enables efficient and reliable fastening operations, making it an ideal choice for industries such as electronics, telecommunications, plastic producers.

View product

Take your production to the next level with the high-speed screw feeders from Optimo Robotics, delivering up to 100 screws per minute for continuous efficiency. These feeders are crafted to fit perfectly together with S1/S2 Screwdrivers or into your current assembly line, representing the ultimate in precision engineering and intelligent automation.

View productThe OPTIMO Robotics S1 Screwdriving System is an advanced, high-precision tool designed for stable screw fastening. The patented operating principle and screwdriving method, is the optimal choice for industries such as electronics, telecommunications, and automotive.

View product

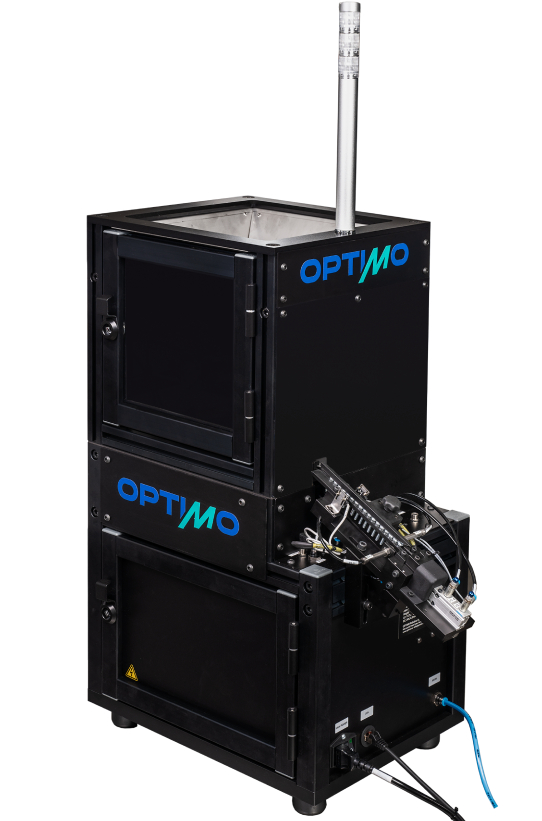

The Screw-driving system package includes:

OPTIMO Robotics screwdriver

OPTIMO Robotics feeding system

OPTIMO Robotics control box with display

URCAP module for Universal Robots on USB drive

Screwdriver spare bits

Yes, our screwdriver and feeder system is designed to handle multiple screw types. However, manual adjustments for screw-specific components are required.

Yes, our screwdriver system can automatically adapt to different screw lengths. To accommodate diverse assembly needs, multiple screw feeders can be integrated into a single screwdriver setup, ensuring a flexible and efficient process for handling various screw sizes simultaneously. However, for varying screw standards or sizes, manual adjustments are required.

The screwdriver system is certified to meet various international standards, ensuring its reliability, safety, and quality. Specific certifications can vary depending on the model and region, so we recommend consulting the product documentation or contacting our support team for detailed information on certifications pertaining to your specific unit.

Yes, the screwdriver system is ESD (Electrostatic Discharge) safe, ensuring protection against any potential static damage during operations.

Integrating the screwdriver system with other machinery or robots typically involves using our provided API or communication protocols, ensuring seamless coordination between devices. Additionally, our technical support team is always on standby to guide you through the integration process step-by-step, ensuring optimal functionality and efficiency.

The screwdriver system is mainly maintenance-free, with only the ballscrew and linear axis requiring periodic lubrication.

Yes, we maintain a stock of replacement parts for the screwdriver system, ensuring quick availability for our customers.

Our robotic screwdrivers are designed and manufactured in Estonia, close to the Tallinn airport.

The Screw-driving System is designed in compliance with the ISO/TS15006 standard, ensuring top-notch quality and reliability. Enhanced by a user-centric graphical interface, integration with Universal Robots is swift and seamless. The flexibility of our system allows for multiple integration scenarios with Universal Robots:

Don't let your business fall behind, stay ahead of the curve with automation! We aim to respond within 24 hours!