Optimo S1 Screwdriver: efficiency and quality with precision and speed!

The art of driving screws

Experience precision and ease with every turn

Welcome to the future of fastening technology – where efficiency, precision, and user-friendly design converge. Our state-of-the-art S1 screwdriver system revolutionizes the way you fasten, re-tighten, and un-tighten. Crafted for simplicity, it empowers users to execute tasks with unparalleled accuracy and speed. Say goodbye to the cumbersome processes of yesterday and embrace a seamless operation. Get ready to drive each screw with confidence, knowing that our patented solution is not just a tool, but a game-changer in hign-precision assembly. Join us in advancing towards a smarter way of working – where every turn is a step towards perfection.

30

Screws / min

Technical specification

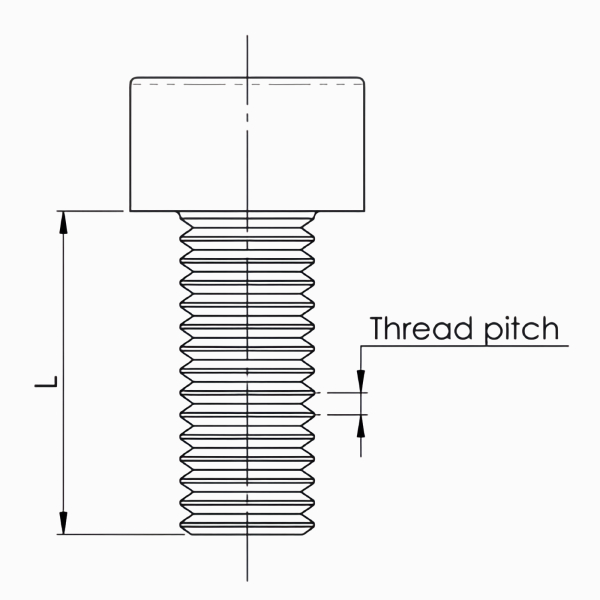

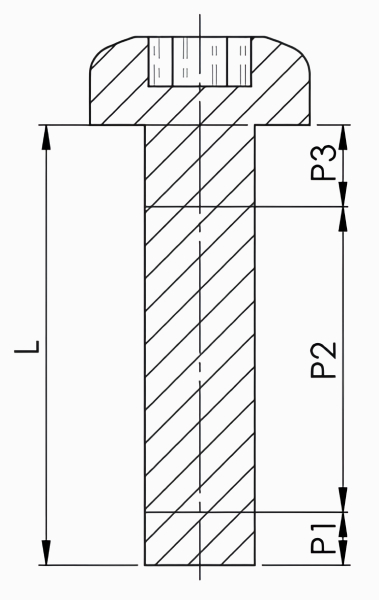

All screw-specific components are modular, ensuring versatility. With a singular system, different screw lengths and sizes can be seamlessly fastened.

Tool vertical precision: ± 0.1mm

The screwdriver's Z-axis boasts high accuracy, ensuring optimal vertical movement during fastening processes with a precision of ± 0.1mm.

Torque: 0.05 – 3.6Nm (±0.05Nm)

The screwdriver system is meticulously calibrated to ensure consistent torque accuracy, ensuring reliable and precise fastening.

Rotational speed: 0–5000 rpm

The screwdriver offers a high rotational capability, up to 5,000 rpm, providing flexibility and precision to accommodate a broad spectrum of assembly applications.

Adaptable to Multiple Screw Sizes and Standards

The screwdriver system is engineered to accommodate a diverse range of fasteners, spanning from M2 to M8, including TORX T4-T30, PH, and various other types.

Interchangeable tip assembly

The screwdriver is equipped with an interchangeable tip assembly, allowing for seamless adaptability to various fastener types.

Full process control

The servo-driven solution ensures precise control over screw speeds and torque. Screws can be tightened based on specified torque or desired insertion depth.

Collaborative screwdriver system

With a built-in safety feature at the tool tip, the system can halt robot operations upon detecting obstacles, ensuring humans can safely share the work area.

Weight: 5.5 kg

For this specific screwdriver configuration, the weight is 5.5 kg. Lighter options are available for configurations with lower torque requirements.

A graphical user interface (GUI) enables full process control

Screw operations and configurations can be efficiently set up through a user-friendly graphical interface in just five steps. Operating the screwdriver necessitates no prior programming expertise.

Step (1 / 5) - Screw specification

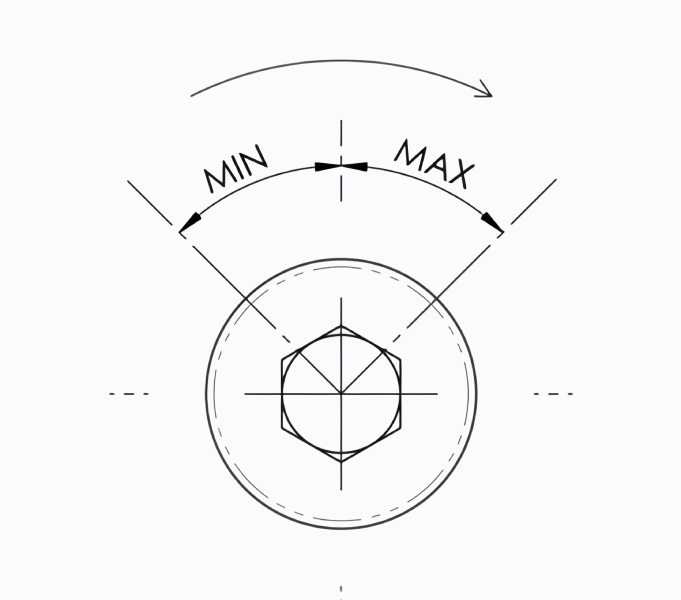

Step (2 / 5) - Angles and speed

Step (3 / 5) - Z-Axis positions

Step (4 / 5) - Screw cycle tolerances

Step (5 / 5) - Finish

1. Screw specification

2. Angles and speed

3. Z-Axis positions

4. Screw cycle tolerances

Easy as that, you’re all set.

Book a free consultation to get a price quote or find out more.

Book free consultaion

Revolutionary Forceless Screwdriving

Precise Torque, Zero Axial Stress

Patented Forceless Screwdriving Technology revolutionizes assembly by using controlled torque to secure screws without the need for axial force, protecting delicate components from stress and strain. This method ensures a gentle yet secure fastening process, making it ideal for precision manufacturing where material integrity is paramount.

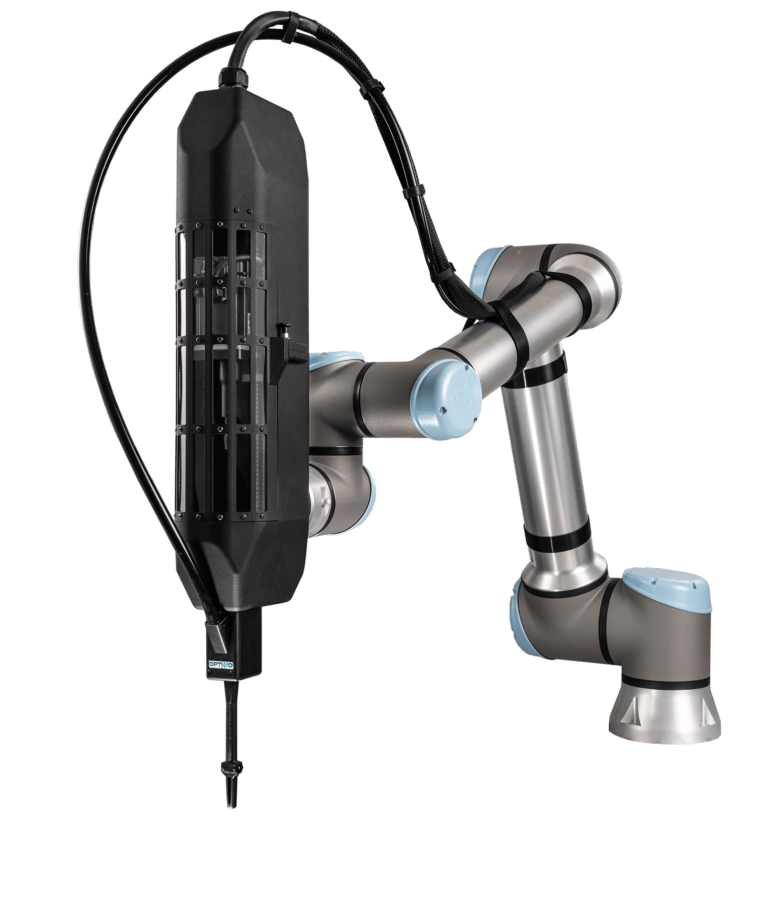

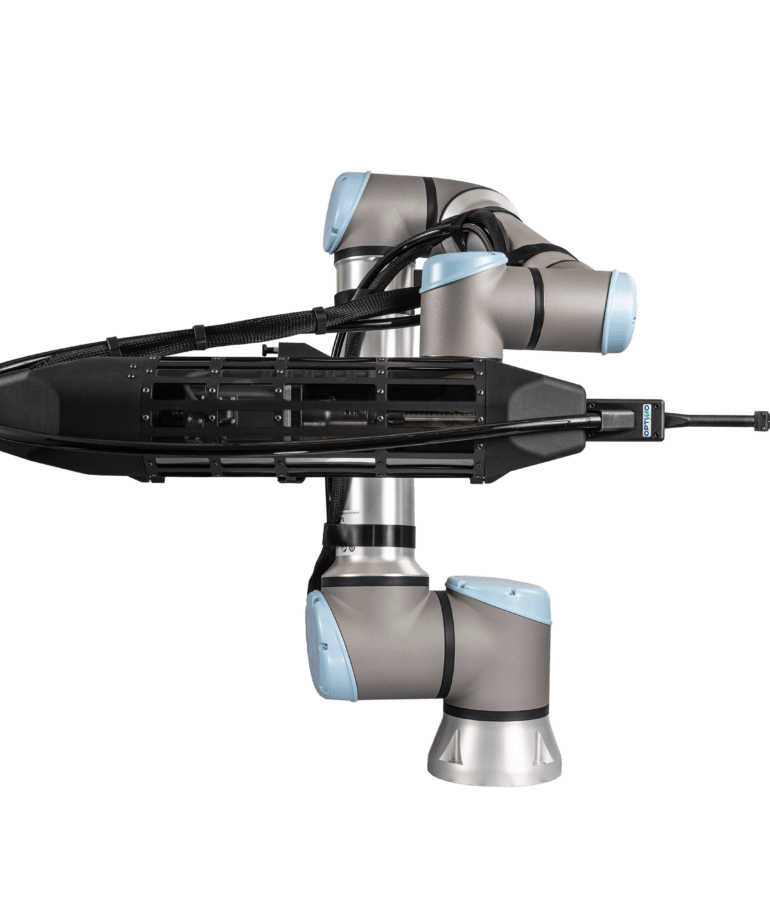

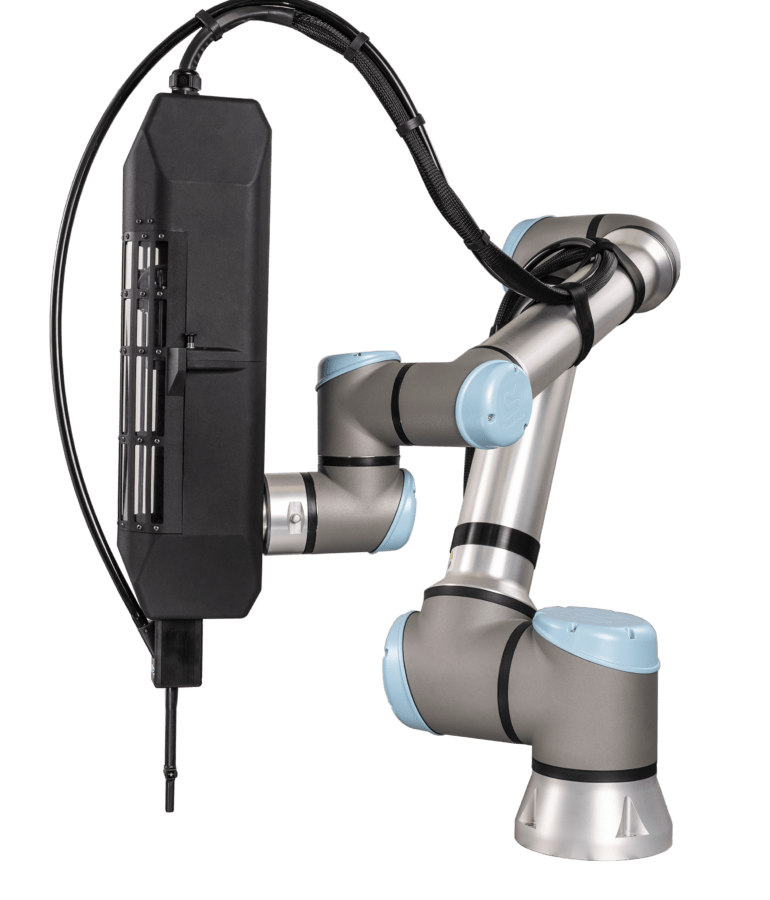

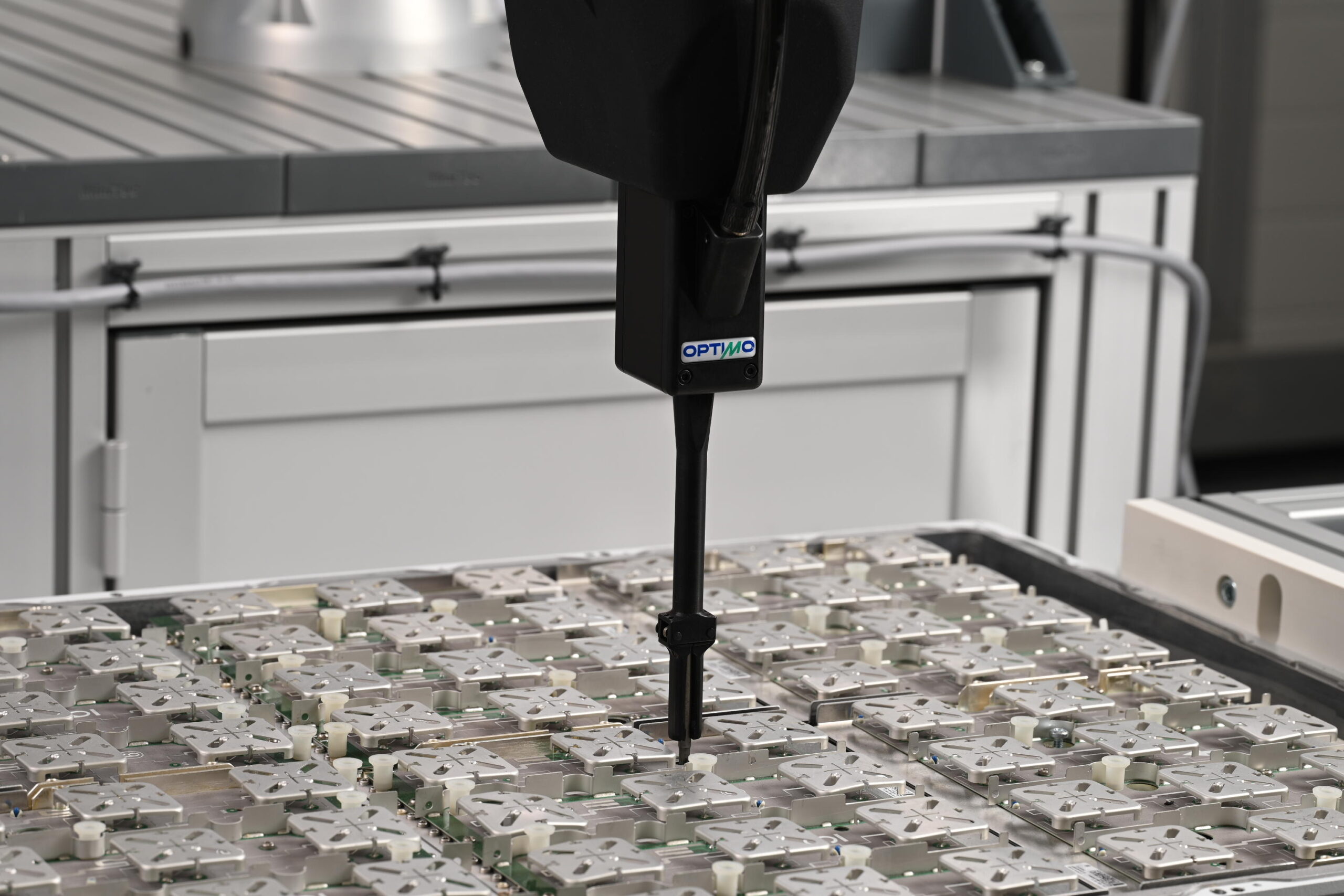

Integration example

CoBot Screwdriving cell for large telecommunication product

- Universal Robots UR10e

- OPTIMO Robotics S1 Screwdriver system for M4 x 20 - TORX T20 Screw

Contact us!

Don't let your business fall behind, stay ahead of the curve with automation! We aim to respond within 24 hours!