Custom robotic solutions

Specializing in sophisticated robotic systems, Optimo Robotics leverages vast experience and innovation to deliver tailored solutions for diverse manufacturing needs globally.

How it works

Our expertise

Optimo Robotics adopts a systematic approach, starting with a thorough analysis of the client's manufacturing needs to select and design the optimal robotic system. They then move through prototyping and validation stages, culminating in the final production, rigorous testing, and expert installation of the robot, ensuring a seamless blend with existing operations.

01

Robot Type Selection and Analysis

Initiate by understanding the customer's specific manufacturing requirements and challenges in the context of robotics. Select and design the appropriate type of robot system that's equipped with the necessary hardware and software components to address those requirements.

02

Development and Prototype Testing

Conceptualize the robotic solution and create a prototype to validate its functionality and efficiency. Obtain approval for the prototype, ensuring it meets customer specifications and industry standards.

03

Final Production and Deployment

Proceed with the final production and assembly of the robotic system. Conduct rigorous tests to confirm the system's performance and reliability. Install the robot system at the customer's facility and ensure seamless integration with their existing manufacturing operations, capitalizing on Optimo Robotics' expertise in robotic integrations.

Solutions for your need

Dive into a future where precision and innovation converge.

Vision-guided robotics

We offer advanced vision-guided robotic solutions, seamlessly integrating visual systems with precision robotics. Our solutions are designed to enhance accuracy and efficiency in complex tasks, enabling robots to adapt to varying environments and tasks with real-time visual feedback. This technology is ideal for applications ranging from intricate assembly processes to quality inspection.

Book a free consultation

Robotics

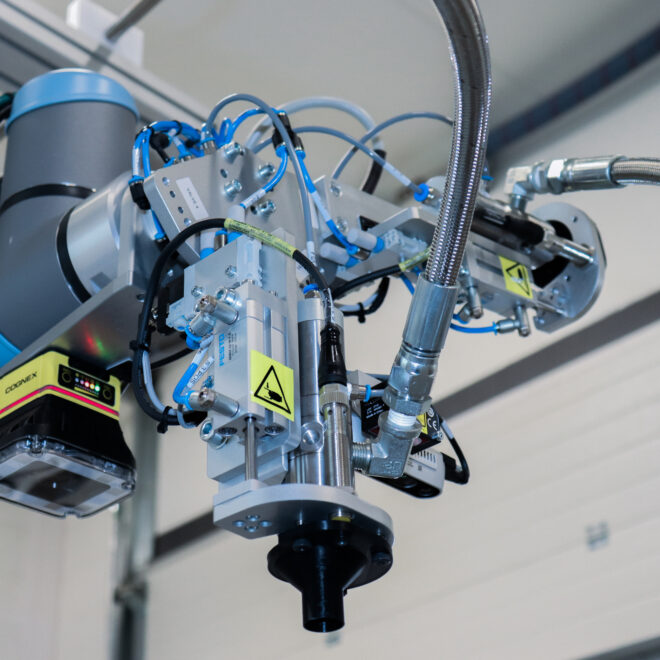

Robotic end-effectors

Our range of robotic end-effectors is designed to provide reliability and precision in handling a variety of tasks, ensuring seamless integration into existing manufacturing processes for optimized productivity.

Book a free consultation

Dive into a future where precision and innovation converge.

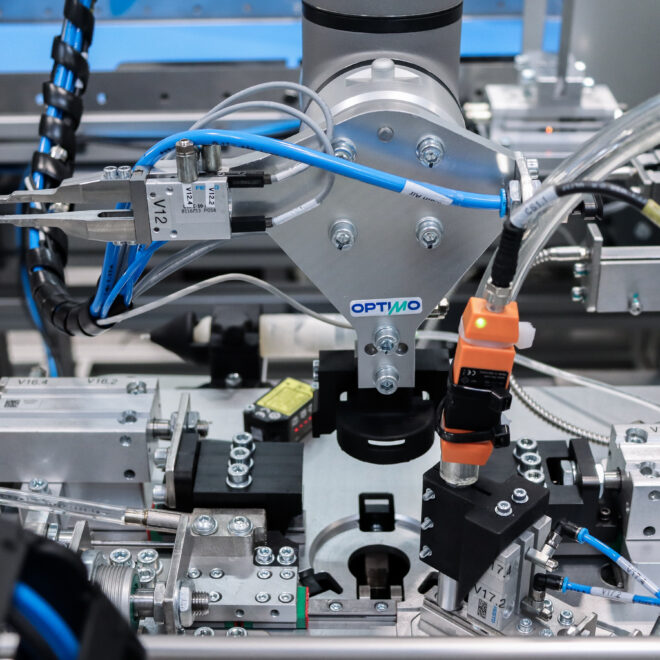

Fixture & workpiece holding

We provide innovative fixture and workpiece holding solutions, designed to secure products and materials with accuracy and reliability, enhancing the stability and quality of manufacturing operations.

Book a free consultation

Robotics

Industrial robots

Our industrial robot solutions are tailored to meet the diverse needs of manufacturers, offering efficient automation options that can significantly elevate productivity and consistency in production lines.

Book a free consultation

Robotics

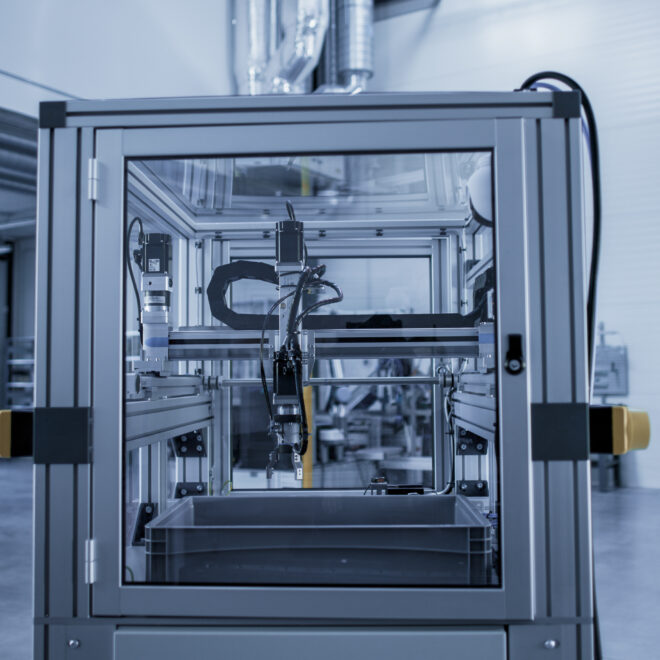

XYZ Gantry robots

We specialize in gantry robot systems, ideal for tasks requiring precise and linear movements, offering manufacturers a high degree of control and flexibility in large-scale and complex automation processes.

Book a free consultation

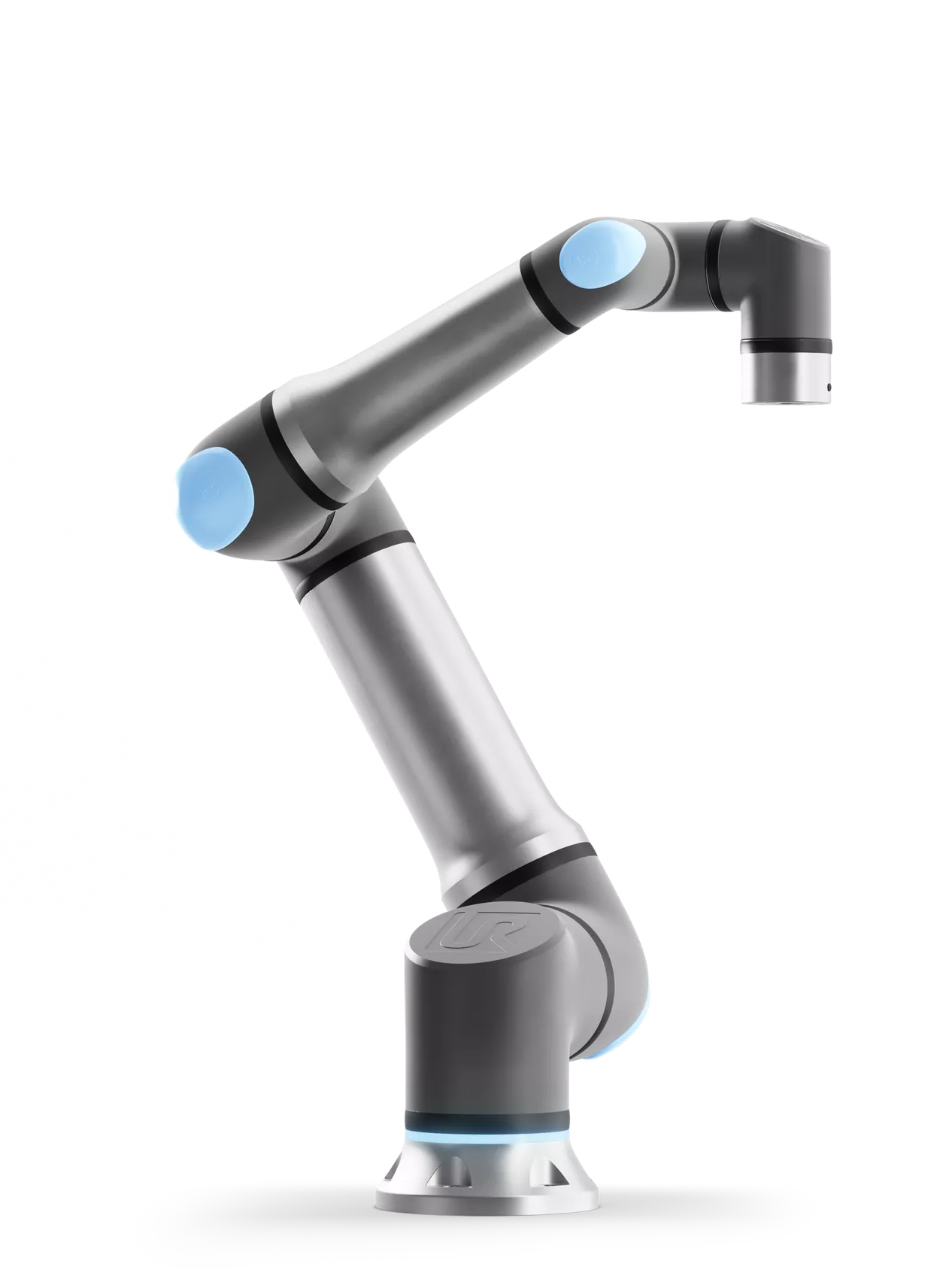

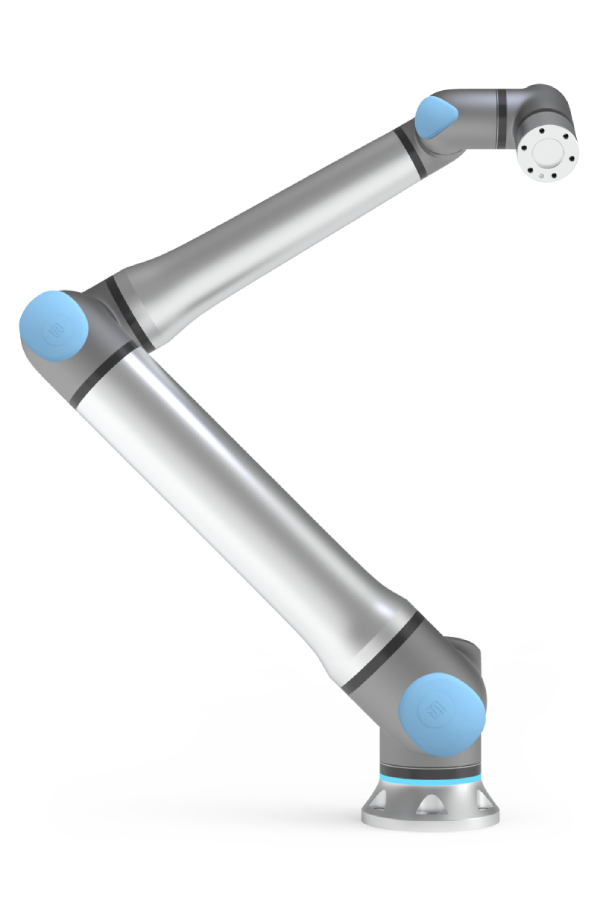

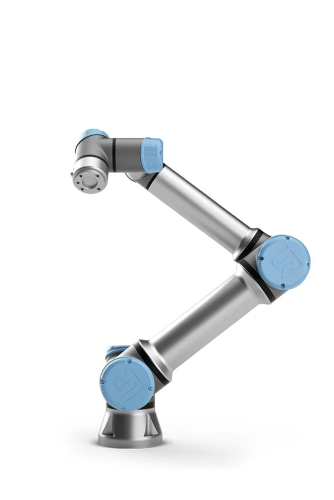

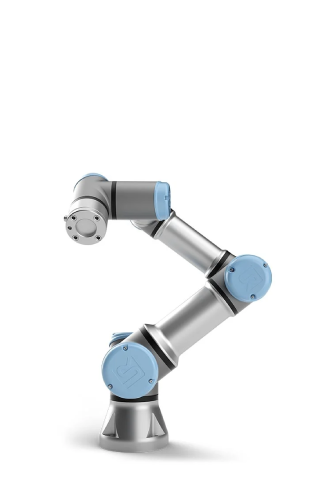

Wide range of top quality Cobots

Universal Robots UR30

Universal Robots UR20

Universal Robots UR16e

Universal Robots UR10e

Universal Robots UR5e

Universal Robots UR3e

Reference projects

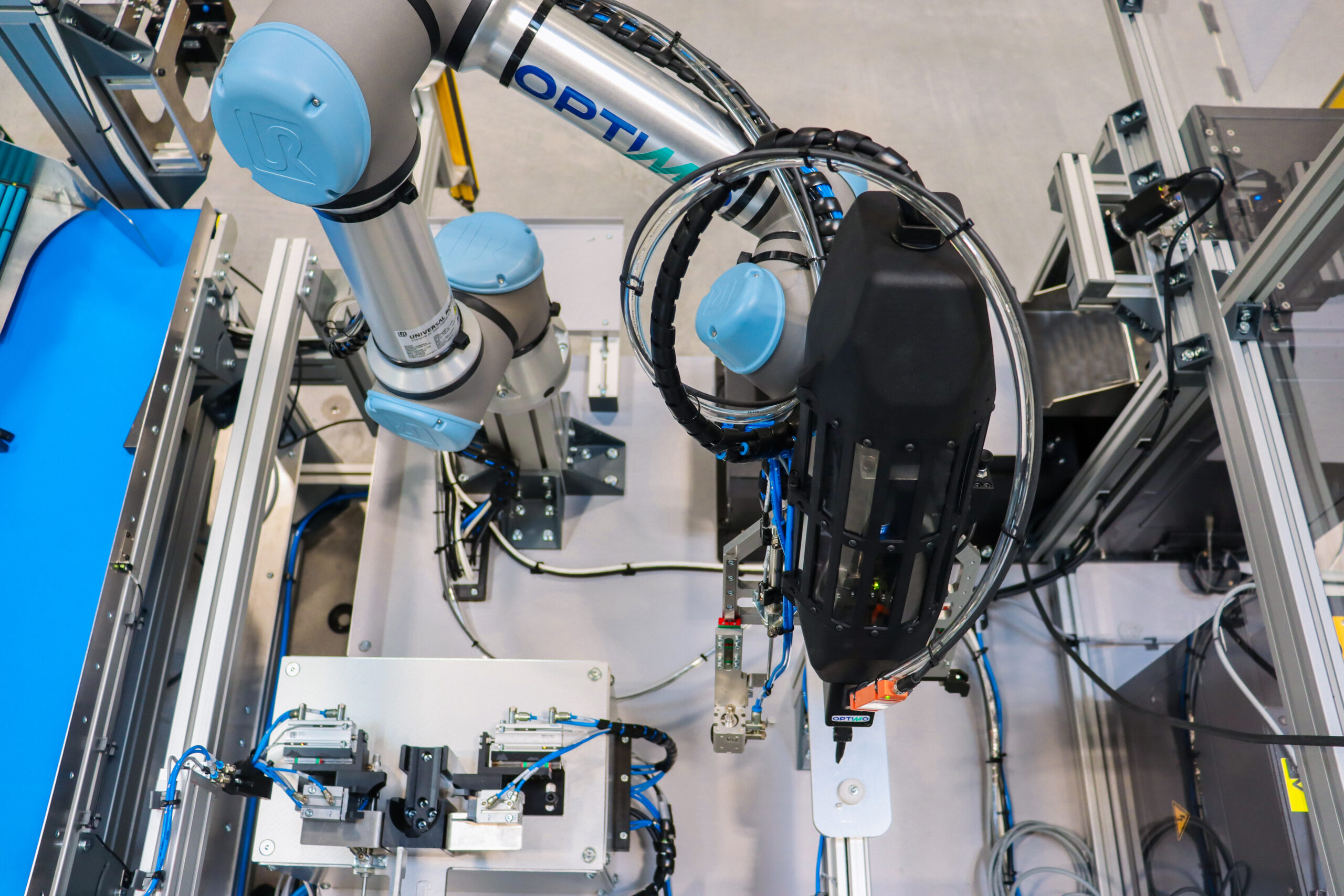

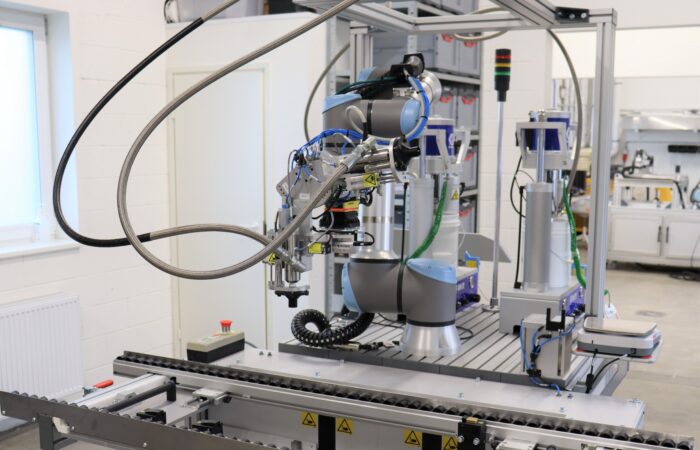

Cobot Screwdriving System

The telecommunications sector, with its complex assembly requirements, posed a unique challenge. The primary task was to develop a robotic screwdriver system that not only meets the specific needs of this industry but also provides the necessary flexibility for high-mix, low-volume production. This equipment needed to comply with global standards, including CE marking, UL compatibility, […]

View use case

Clips Assembly Robotic System

The goal of this project was to develop a highly efficient and compact robotic system for assembling metal clips into plastic products. The system needed to fit within a limited space of 900 x 1200 x 1150 mm and achieve a rapid assembly cycle time of 3 seconds per clip.

View use case

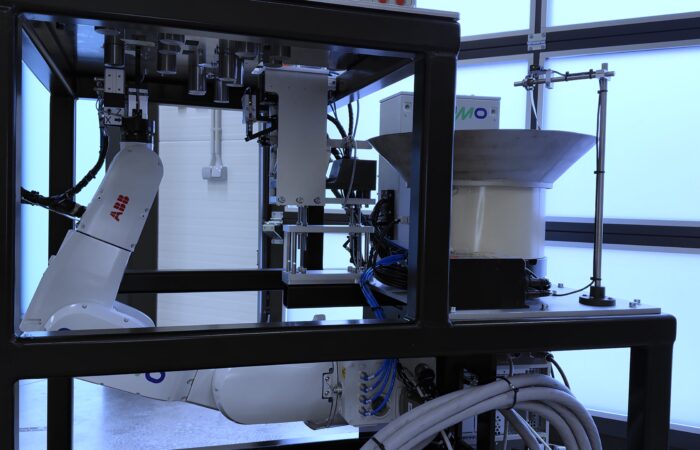

Thermal Paste Dispensing System

Thermal Paste Dispensing Robots are crucial for telecommunication producers. As telecommunication equipment often involves high-performance electronics that generate heat, maintaining optimal temperatures is essential for performance and longevity. These robots precisely apply thermal paste to components like PCBs, processors, and other heat-generating elements.

View use case

Robotic solutions for different applications

- Assembly systems - Screwdriving systems - Conveyor systems - Dispensing systems - Test systems

We at Ericsson Eesti AS greatly appreciate OPTIMO Robotics' exceptional collaboration and support throughout the years. Your team has consistently provided valuable insights and innovative ideas, helping us explore and implement the latest robotic, tightening and dispensing technologies. Your commitment to excellence and unwavering dedication to our success has been commendable. We look forward to continuing our partnership and leveraging your expertise to drive growth and success.

Marek Arru

Head of Final Assembly Technology - Ericsson Eesti AS

Contact us!

Don't let your business fall behind, stay ahead of the curve with automation! We aim to respond within 24 hours!