Optimo S2 Mini Screwdriver: lightweight with precision and speed!

The art of driving screws

S2 Mini Robotic Screwdriver

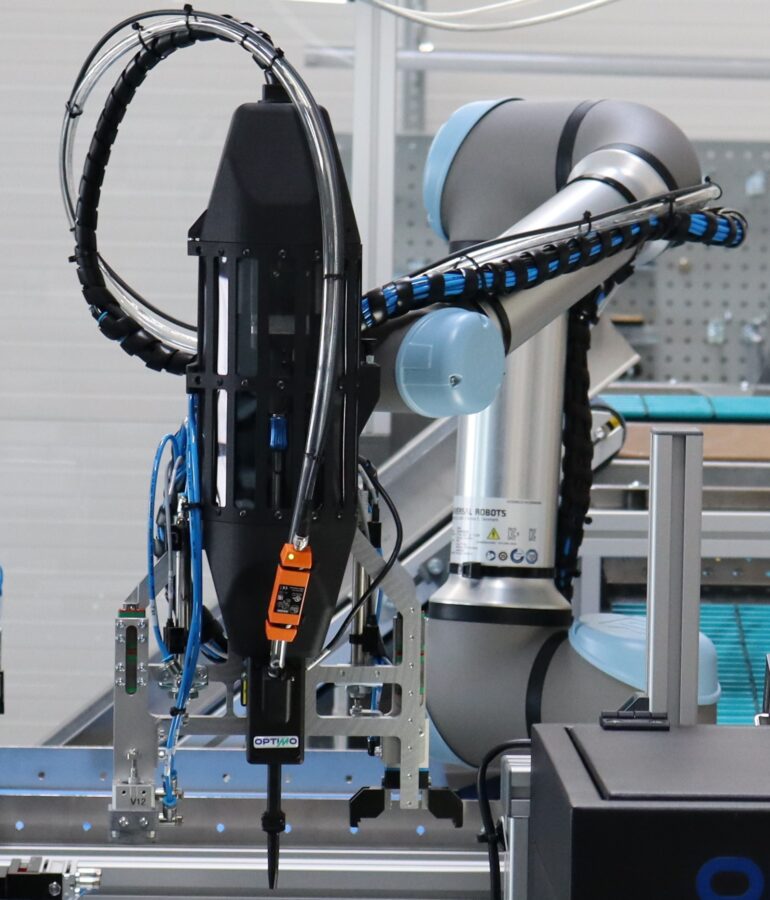

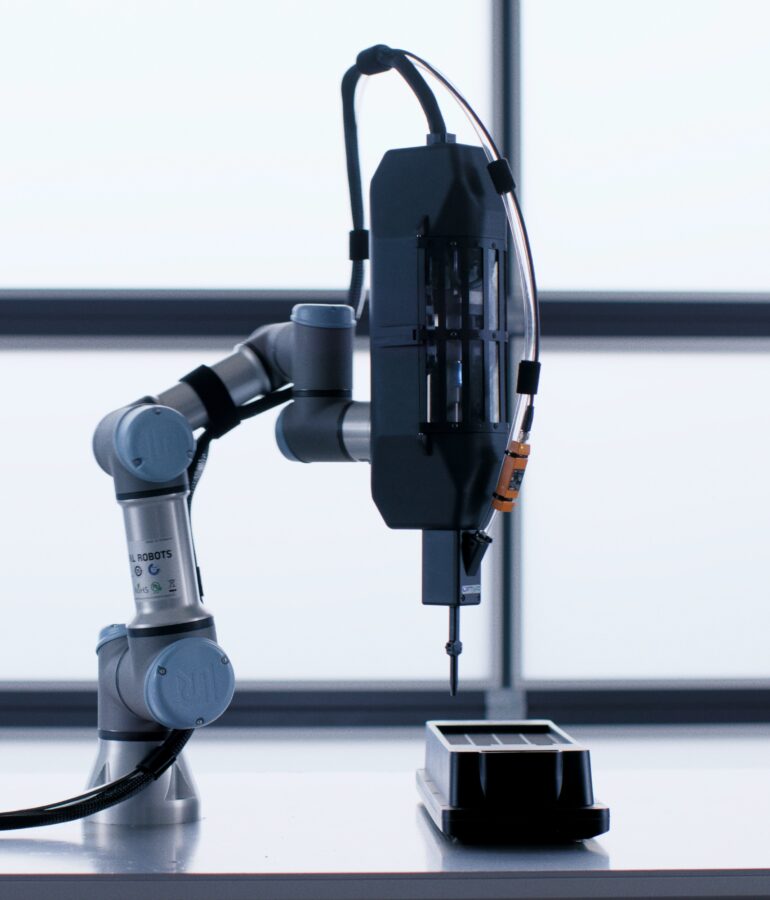

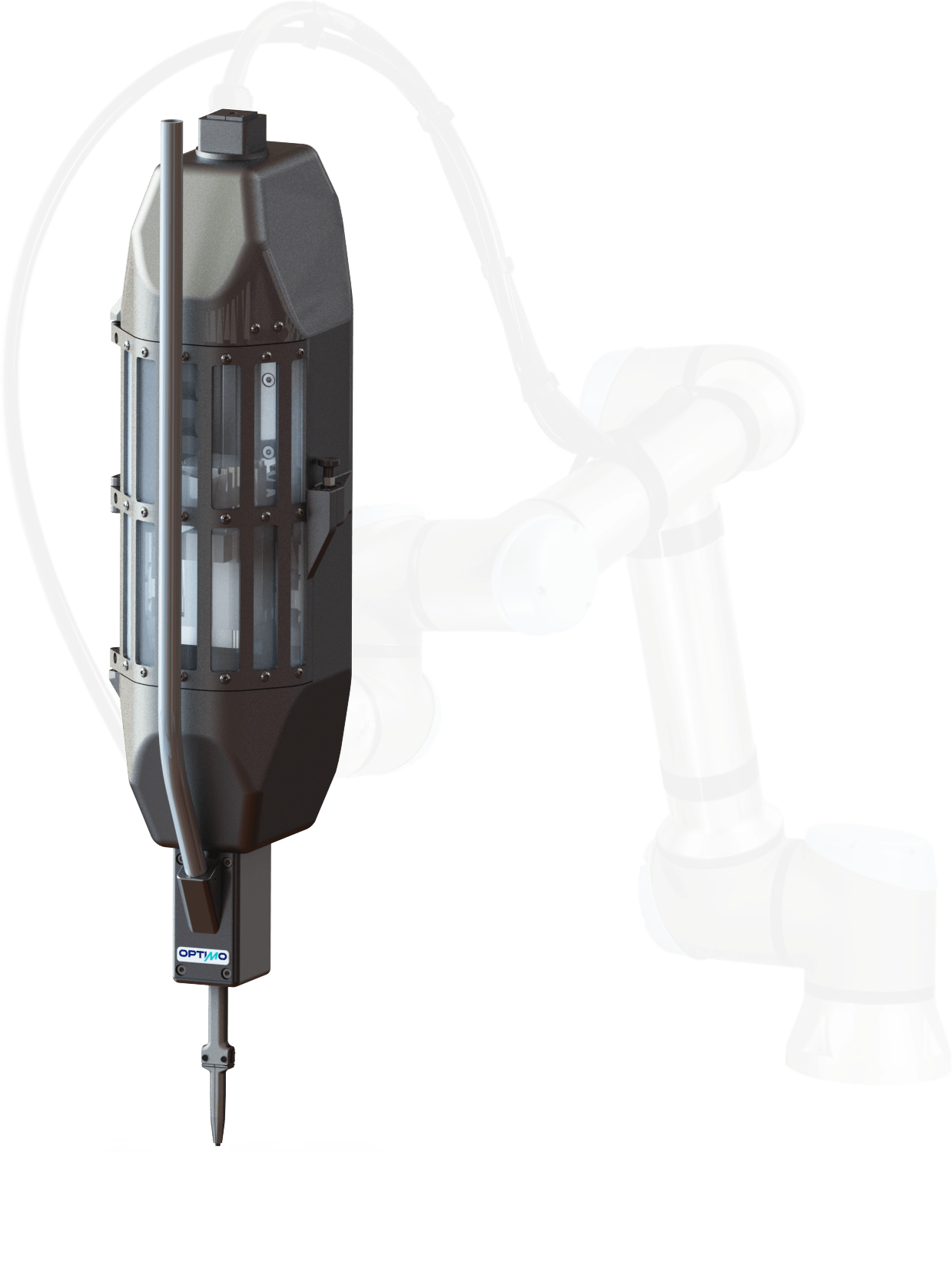

Enter the future of fastening technology with the Optimo Robotics S2 Screwdriver System, a perfect fusion of lightweight construction and user-centered design. Engineered for simplicity and efficiency, the S2 allows users to perform tasks with remarkable speed and accuracy. Enhanced by its pneumatic Z-axis, the S2 offers smooth and effortless movement during screwdriving cycle.

30

Screws / min

Technical specification

All screw-specific components are modular, ensuring versatility. With a singular system,different screw lengths and sizes can be seamlessly fastened.

Tool vertical movement: pneumatical

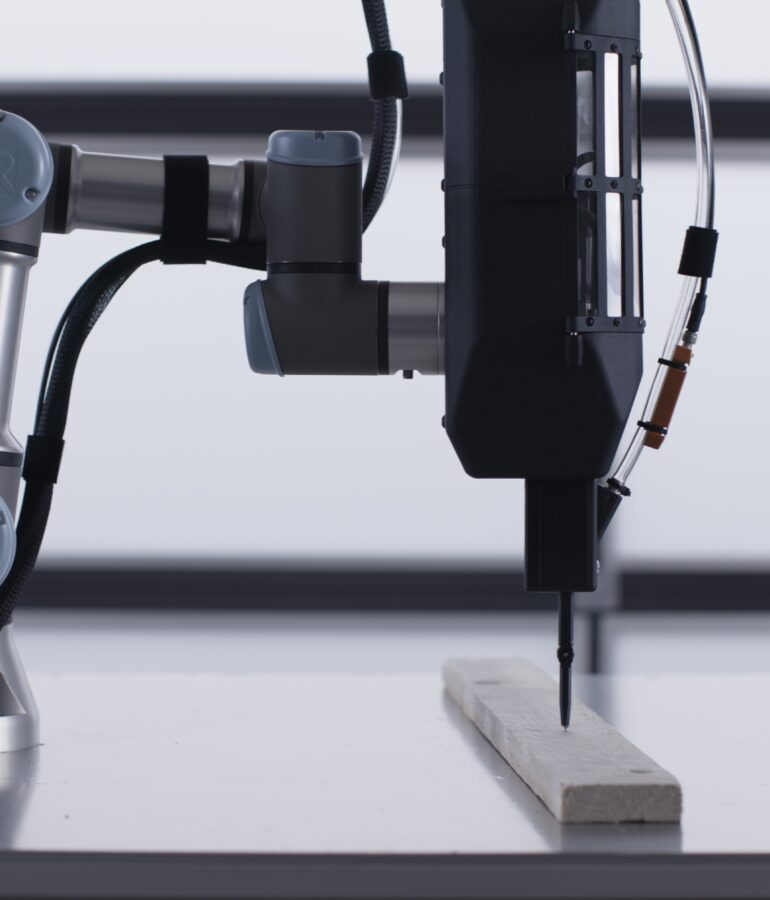

The Z-axis vertical movement is pneumatically controlled, featuring adjustable screw pressing force.

Torque: 0.05 – 1.1Nm

The screwdriver system is meticulously calibrated to ensure consistent torque accuracy, ensuring reliable and precise fastening.

Rotational speed: 0–5000 rpm

The screwdriver offers a high rotational capability, up to 5,000 rpm, providing flexibility and precision to accommodate a broad spectrum of assembly applications.

Adaptable to Multiple Screw Sizes and Standards

The screwdriver system is engineered to accommodate a diverse range of fasteners, spanning from M3 to M8, including TORX T5-T30, PH, and various other types.

Interchangeable tip assembly

The screwdriver is equipped with an interchangeable tip assembly, allowing for seamless adaptability to various fastener types.

Full process control

The servo-driven solution ensures precise control over screw speeds and torque. Screws can be tightened based on specified torque or desired insertion depth.

Collaborative screwdriver system

With a built-in safety feature at the tool tip, the system can halt robot operations upon detecting obstacles, ensuring humans can safely share the work area.

Weight: 2.3 kg

Its lightweight design makes it ideal for the smallest robots.

Contact us!

Don't let your business fall behind, stay ahead of the curve with automation! We aim to respond within 24 hours!