Automated Screwdriving Systems for Manufacturers

In the world of manufacturing, efficiency and precision are key. That’s why automated screwdriving systems have become an essential tool for many companies. These systems have changed how assembly tools use, making the process faster, more accurate, and cost-effective. This post discusses how automated screwdriving systems are changing manufacturing processes for the better.

What are Automated Screwdriving Systems?

Automated screwdriving systems are a crucial component of modern manufacturing processes, as they streamline the assembly line and increase efficiency. These systems are equipped with advanced technology that allows them to accurately insert screws into products with precision and speed.

One of the key features of automated screwdriving systems is their automated feeding mechanism, which ensures a continuous supply of screws to the machine. This eliminates the need for manual loading of screws, saving time and reducing the risk of errors.

In addition to inserting screws, automated screwdriving systems are capable of performing a variety of tasks, such as tightening screws to a specific torque, loosening screws for maintenance or repair purposes, and then retightening them. This versatility makes these systems highly adaptable to different manufacturing needs and product requirements.

Overall, automated screwdriving systems play a crucial role in modern manufacturing processes by increasing productivity, improving product quality, and reducing labor costs. Their ability to perform a wide range of tasks with precision and efficiency makes them an essential tool for companies looking to stay competitive in today’s fast-paced market.

Increased Efficiency and Speed

One of the biggest advantages of using automated screwdriving systems is the increase in efficiency and speed. These systems are able to drive screws at a much faster rate than manual labor, resulting in a significant increase in production output. This is especially beneficial for high-volume production lines where time is of the essence.

Improved Accuracy and Consistency

In addition to speed, automated screwdriving systems also offer improved accuracy and consistency. These systems are programmed to drive screws to a specific torque and depth, ensuring that each screw is placed correctly every time. This eliminates the risk of human error and ensures that all products are assembled to the same high standard.

Customization Options

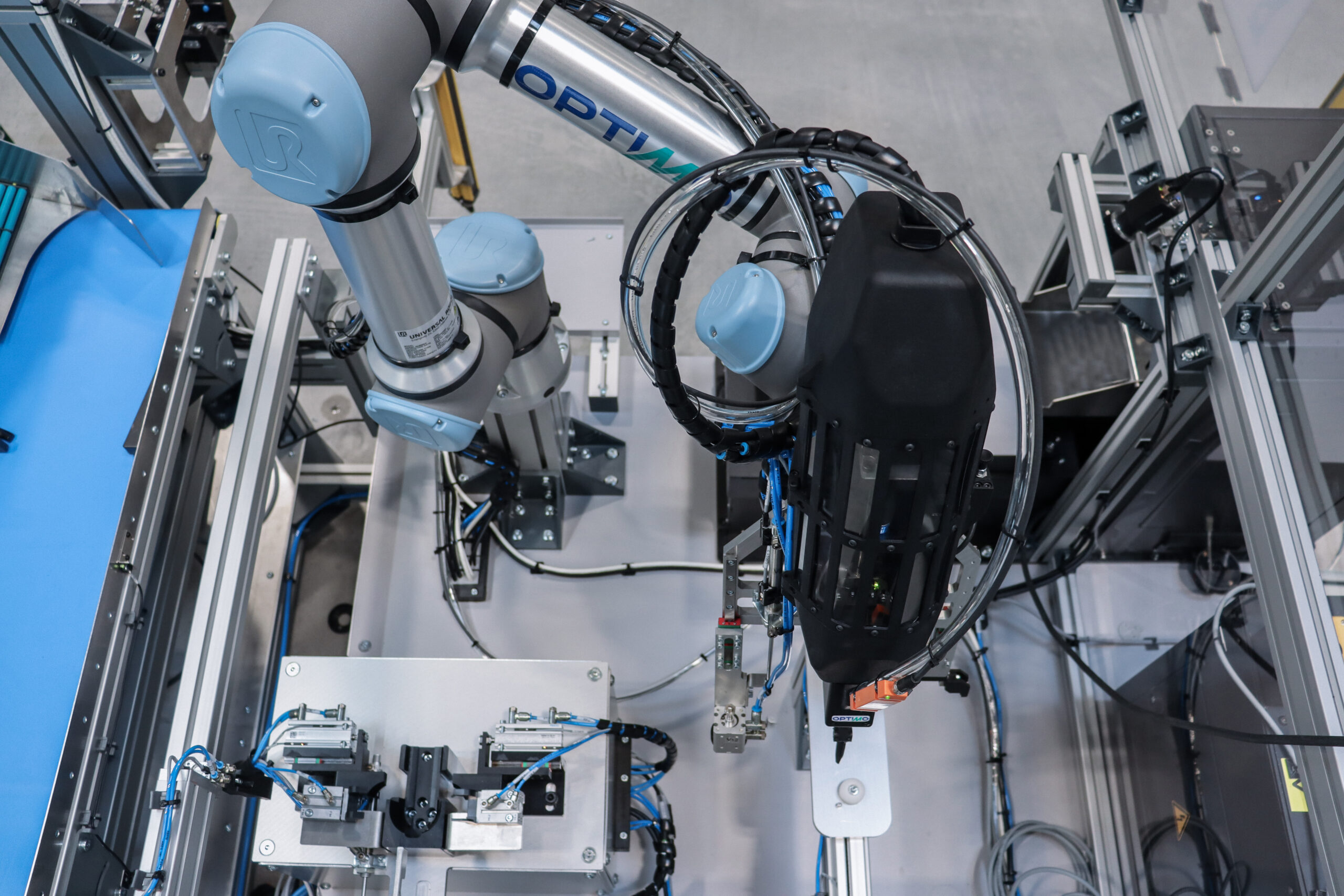

Optimo Robotics specializes in creating customized screwdriving solutions that are specifically designed to meet the unique needs of each customer. By offering a wide variety of options for different types of fasteners, including screws, bolts, and nuts, Optimo Robotics ensures that their solutions can be easily integrated into any assembly process. This level of flexibility allows for seamless integration with existing equipment and workflows, ultimately improving efficiency and productivity.

In addition to flexibility, Optimo Robotics also prioritizes precision in their screwdriving solutions. By utilizing advanced technology and high-quality components, their systems are able to consistently deliver accurate and reliable results.

Overall, Optimo Robotics’ tailored screwdriving solutions offer a comprehensive approach to improving assembly processes.

Conclusion

Automated screwdriving systems revolutionize the way manufacturing uses assembly tools. With their speed, accuracy, and cost-saving benefits, these systems have become an essential tool for many companies. As technology continues to advance, we can expect to see even more improvements and innovations in automated screwdriving systems, making them an indispensable part of the manufacturing process.