Robotic and Automatic Screwdriving Solutions

Robotic integrations and factory automation solutions

Revolutionize your manufacturing with our automation and robotic integration services.

Revolutionize your manufacturing with our automation and robotic integration services.

About us

Optimo Robotics OÜ, established in 2014, has evolved from the engineering company ESTEG. Initially, we offered engineering services to manufacturing companies, but over time our focus shifted to robotics and manufacturing automation. As a modern engineering company, we strive to develop innovative solutions and deliver professional engineering services. Our goal is to provide exceptional value to our clients through our expertise in robotics and automation.

More about usBestsellers

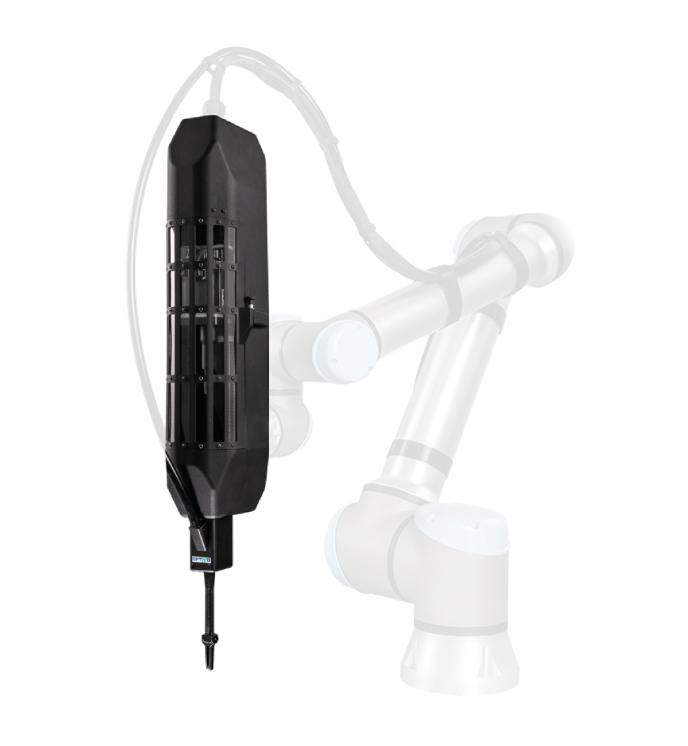

Transform the way you work with our revolutionary robot screwdriver, designed to make your complex screw driving tasks effortless and precise. Forget the tedious, time-consuming and error-prone manual screwdriving and hello to increased productivity and satisfaction.

View products

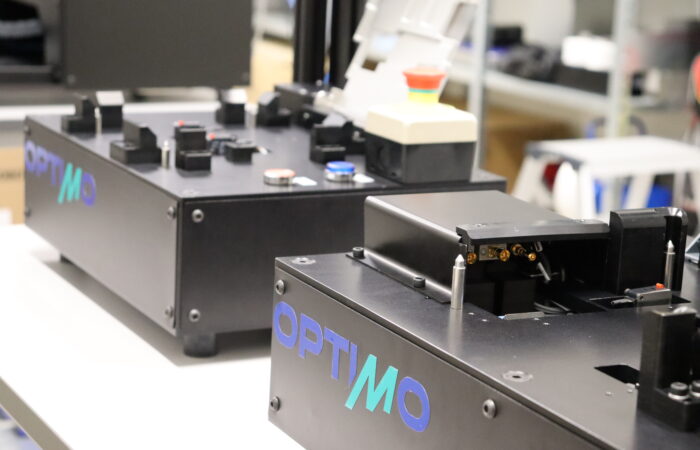

Maximize productivity with Optimo's high-performance Screw Feeders - the ideal solution for fast, efficient automatic screw feeding. With pneumatic air-powered operation, speeds of up to 2 screws per second, and compatibility with various screw types and sizes, our feeders optimize production. The built-in light tower provides real-time status updates, and the 5 dm³ feeder capacity is expandable for specific needs.

View products

We provide bespoke engineering and machine-building services tailored to the unique production needs of your company.

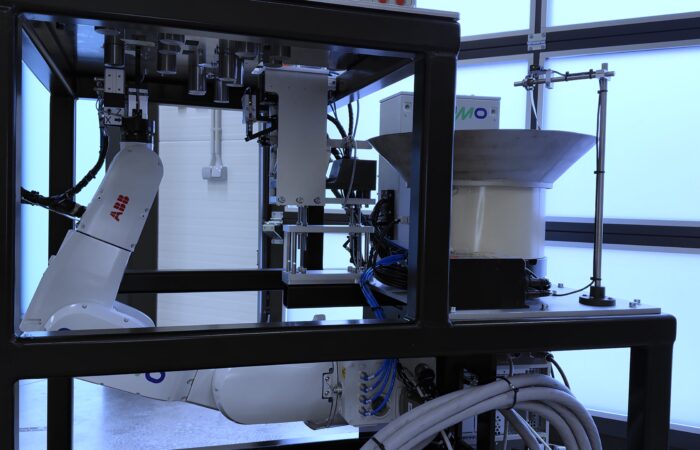

Find out moreRobotic solutions development in collaboration with various robot providers such as Universal Robots, ABB, Fanuc, Kuka, Omron.

Find out moreGet the job done more quickly and accurately, all while reducing the risk of injury or strain. Upgrade your screwing game with a reliable and efficient robot screwdriver today!

Find out moreThe telecommunications sector, with its complex assembly requirements, posed a unique challenge. The primary task was to develop a robotic screwdriver system that not only meets the specific needs of this industry but also provides the necessary flexibility for high-mix, low-volume production. This equipment needed to comply with global standards, including CE marking, UL compatibility, […]

View use case

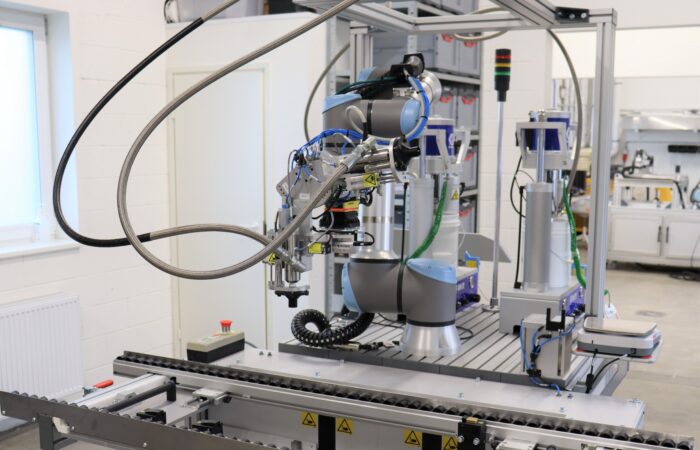

The goal of this project was to develop a highly efficient and compact robotic system for assembling metal clips into plastic products. The system needed to fit within a limited space of 900 x 1200 x 1150 mm and achieve a rapid assembly cycle time of 3 seconds per clip.

View use case

Thermal Paste Dispensing Robots are crucial for telecommunication producers. As telecommunication equipment often involves high-performance electronics that generate heat, maintaining optimal temperatures is essential for performance and longevity. These robots precisely apply thermal paste to components like PCBs, processors, and other heat-generating elements.

View use case

The production of an electronic product required a sequence of detailed assembly operations, each demanding precise product alignments, and fixture-based workflows. The variability in tasks – from SSD insertion and thermal padding to end-of-line labelling – presented a significant challenge that necessitated seamless collaboration between human and machine.

View use case

Marek Arru

Head of Final Assembly Technology - Ericsson Eesti AS

Don't let your business fall behind, stay ahead of the curve with automation! We aim to respond within 24 hours!