From an idea to reality

Transforming visions into tangible solutions. Our expertise lies in seamlessly blending industrial automation with your unique manufacturing processes.

How it works

Our expertise

From identifying client-specific manufacturing needs and developing tailored robotic solutions, through to production, implementation, and training, we conclude with comprehensive aftercare that includes ongoing support, maintenance, system updates, and potential upgrades to continually meet evolving client requirements.

01

Analysis and Development

We start by identifying the customer's specific manufacturing needs and challenges, and then proceed to conceptualize and design a suitable robotic system, complete with necessary hardware and software.

02

Production and Implementation

Following the creation of a prototype and its approval, we move onto the final production, assembly, rigorous testing, and verification of the system. This phase also includes installing the system at the customer's site, ensuring seamless integration into existing operations.

03

Training and Support

We offer comprehensive staff training on system operation and provide complete documentation for future reference. Our commitment continues with ongoing support, regular maintenance, system updates, and potential upgrades to meet evolving customer needs.

Solutions for your need

Dive into a future where precision and innovation converge.

Engineering & Development

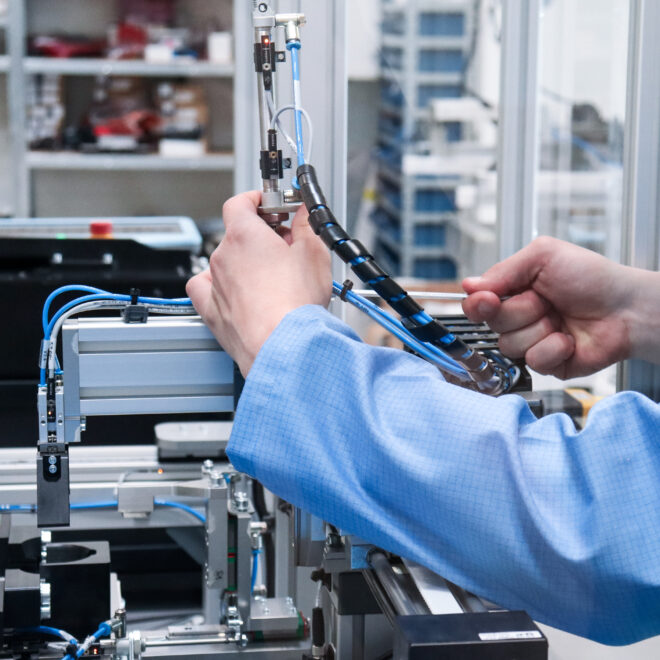

In our 'Engineering & Development' department, a talented team excels at turning ideas into real-world solutions. We specialize in a range of areas including mechanical engineering, electrical systems, and pneumatics. Our approach is comprehensive, ensuring every aspect of your project is handled with care and innovative thinking.

Book a free consultation

Dive into a future where precision and innovation converge.

Programming

Explore the possibilities of automation with our expert programming services. We specialize in PLC systems and robot programming, offering customized solutions for seamless integration and optimized performance. Our skilled team is dedicated to understanding and meeting your specific needs, ensuring each project is executed with precision and efficiency.

Book a free consultation

Dive into a future where precision and innovation converge.

Mechanical & electrical assembling

Our assembly team is proficient in uniting complex parts and systems, creating products that are both dependable and high-performing. With our extensive knowledge in both mechanical and electrical fields, we guarantee your projects are completed with exceptional accuracy and the highest standards of quality.

Book a free consultation

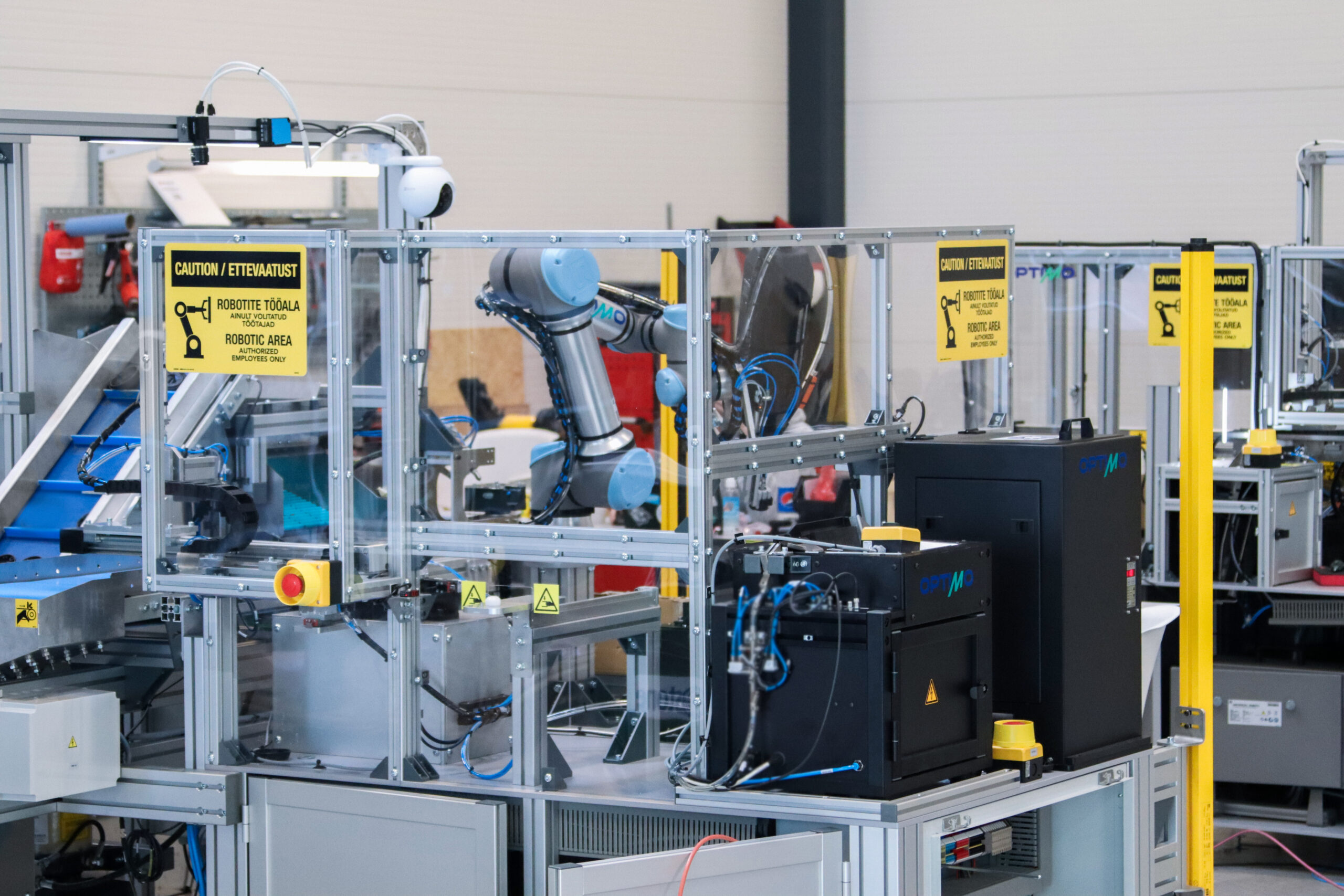

Robotics

Installation and support

We also provide comprehensive installation and support services, ensuring that every system is set up for optimal performance. Our dedicated support team stands ready to assist, guaranteeing smooth operations and prompt resolutions to any challenges you may encounter.

Book a free consultation

Suitable for various manufacturers

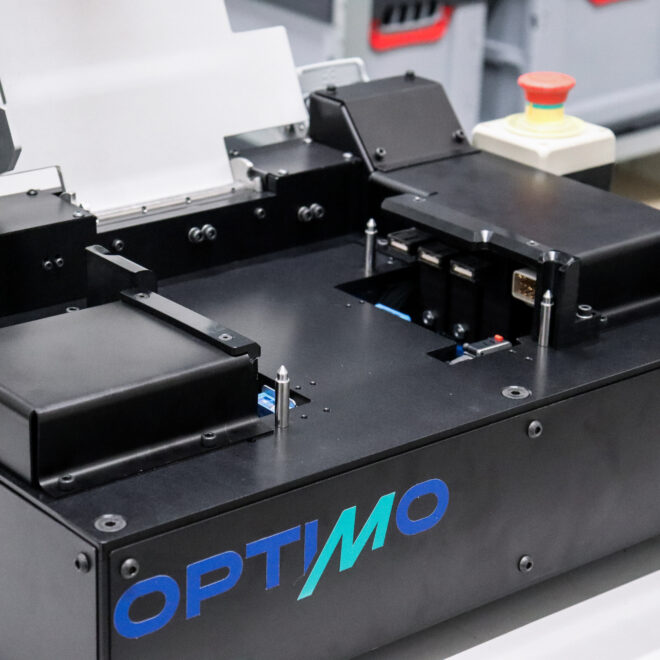

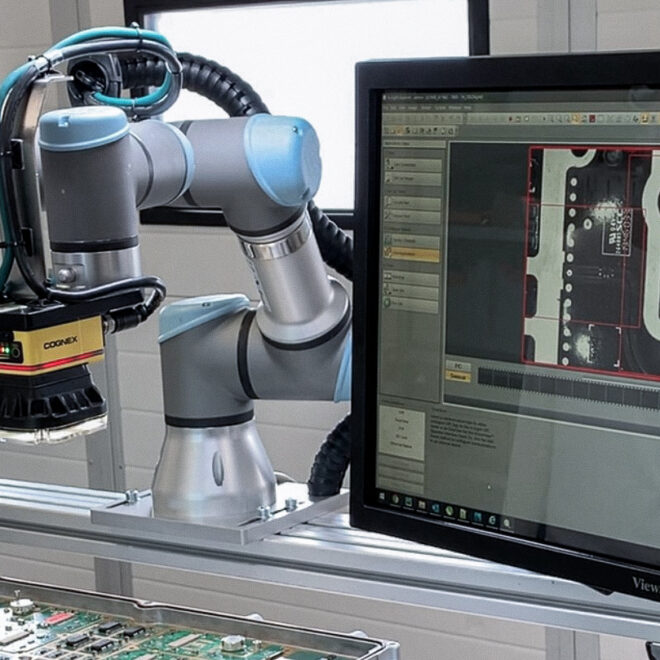

Assembly and Test Fixtures with machine vision

The production of an electronic product required a sequence of detailed assembly operations, each demanding precise product alignments, and fixture-based workflows. The variability in tasks – from SSD insertion and thermal padding to end-of-line labelling – presented a significant challenge that necessitated seamless collaboration between human and machine.

View use case

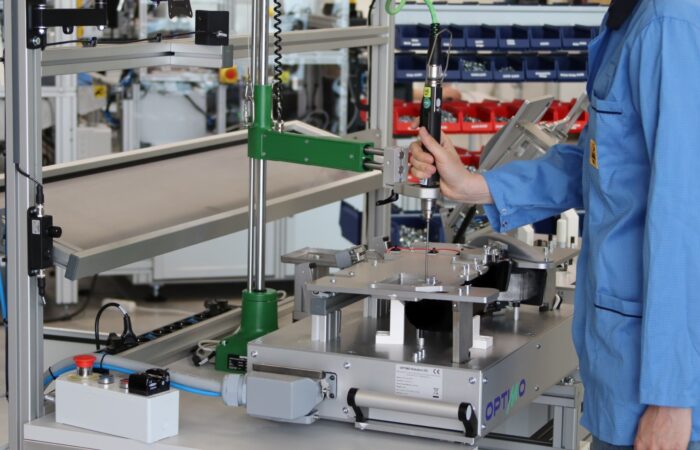

Screw-driving Workstation with Assembly Fixtures

The project involves the development and production of specialized screwdriving and production assembly equipment, designed to facilitate the efficient assembly of plastic covers onto aluminum bodies. Following the assembly process, the parts will be securely fastened together using screws. The equipment includes an electrically height-adjustable workstation, an electrical cabinet equipped with a PLC, custom assembly […]

View use case

Clips Pressing Fixtures with Workstation

To ensure a seamless integration of both manual and automated operations in the assembly of metal clips to plastic covers, our system guarantees precise part positioning and secure fixation during the process. This approach, all within a single assembly fixture, provides consistent quality assurance and efficiency.

View use case

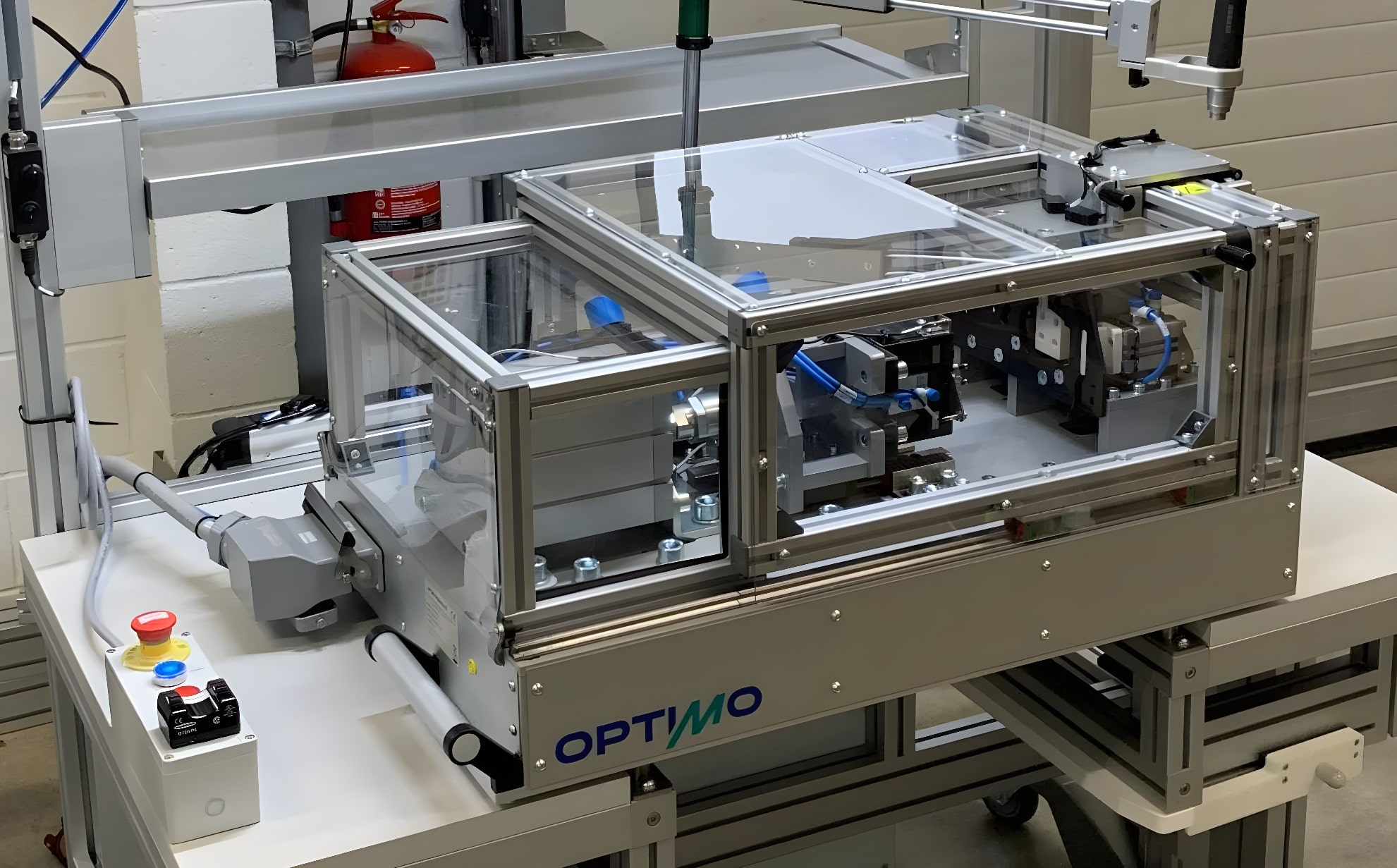

Pressing and Screwing Fixtures with Workstation

This project involves the development and production of specialized production assembly equipment, specifically designed to enable accurate press-fitting and screwing. After the press-fitting process, parts will be securely joined using screws. The equipment features an electrically height-adjustable workstation and an electrical cabinet outfitted with a Siemens S1200 programmable logic controller. Additionally, it includes custom assembly […]

View use case

Streamlined automation, personalized touch

Optimo Robotics brings a personal touch to the world of automation with tailored approach to your factory's heartbeat. Each system, a blend of robots, feeders, machine vision, and precision, is like a handcrafted puzzle piece designed to fit perfectly into your production story.

Solutions for your need

Dive into a future where precision and innovation converge.

Mobile Industrial Robots and accessories

Specializing in standard mobile industrial robots, we assist manufacturers in programming and integration into their workflow. Additionally, we offer an array of accessories for mobile industrial robots, including conveyors, lifters, and more to optimize your automation processes.

Book a free consultation

Dive into a future where precision and innovation converge.

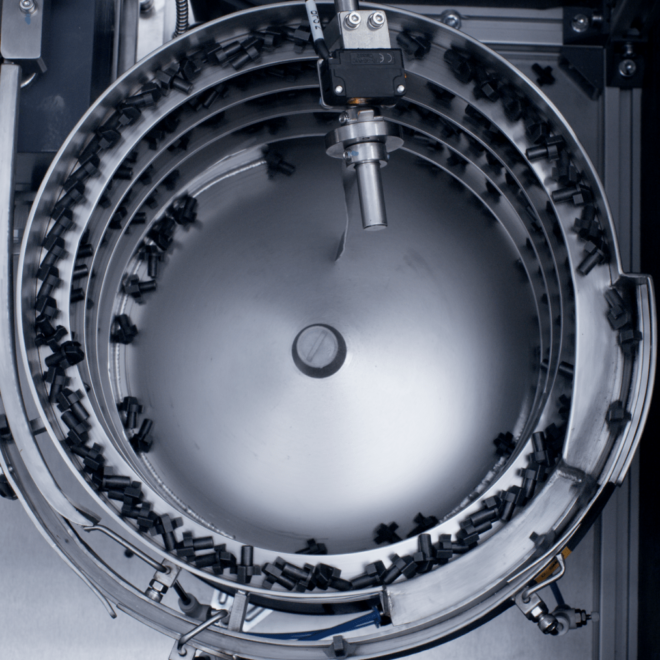

Component feeding solutions

Optimize your robotic operations with our component feeding solutions. Our range of devices, including bowl feeders, step feeders, flexible feeders and tray feeders, expertly organizes and aligns parts for seamless robot interaction. These systems consistently supply components to robotic and automation systems.

Book a free consultation

Roller conveyors, Belt conveyors, Chain conveyors, etc.

Conveyor systems

Our advanced conveyor systems are engineered to enhance the efficiency and flow of your manufacturing processes. We offer a wide range of conveyors, including roller, belt, and chain options, each designed to meet the specific material handling needs of various industries.

Book a free consultation

Dive into a future where precision and innovation converge.

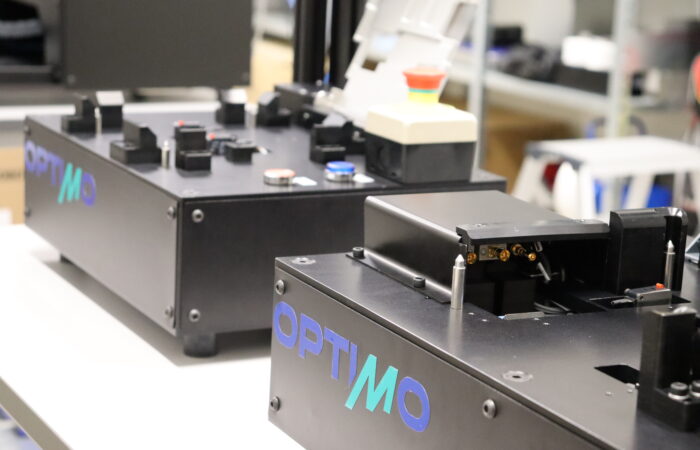

Assembly & test fixtures

Improve your manufacturing efficiency with our assembly and test fixtures, custom-designed for your specific production requirements. Our skilled team develops each fixture with precision, focusing on accurate assembly and comprehensive testing to streamline your processes and achieve superior results.

Book a free consultation

Dive into a future where precision and innovation converge.

ESD Workstations

Upgrade your workspace with our ESD (Electrostatic Discharge) compliant manual and semi-manual workstations, ensuring safety and precision in electronics handling. Our workstations provide optimal protection against static-induced damages while streamlining your assembly and testing processes.

Book a free consultation

Dive into a future where precision and innovation converge.

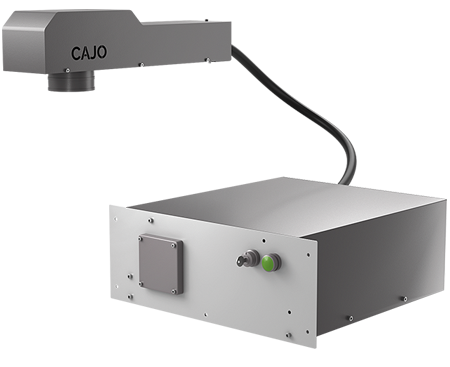

Laser marking

Increase your product identification and traceability with our laser marking solutions. We provide precise, durable, and high-quality marking services to meet the most rigorous standards and branding requirements.

Book a free consultation

Dive into a future where precision and innovation converge.

Machine vision

At Optimo Robotics, we specialize in developing Machine Vision applications to enhance manufacturing processes. Our services include color recognition, reading and verifying text and numbers through optical character recognition and optical character verification , as well as detecting various types of barcodes and matrix codes. These capabilities are essential in inspecting assembly components, confirming the presence and correct placement of parts, assessing product geometry, and conducting quality control with precise dimensional measurements.

Book a free consultation

Contact us!

Don't let your business fall behind, stay ahead of the curve with automation! We aim to respond within 24 hours!