Assembly and Test Fixtures with machine vision

Project description

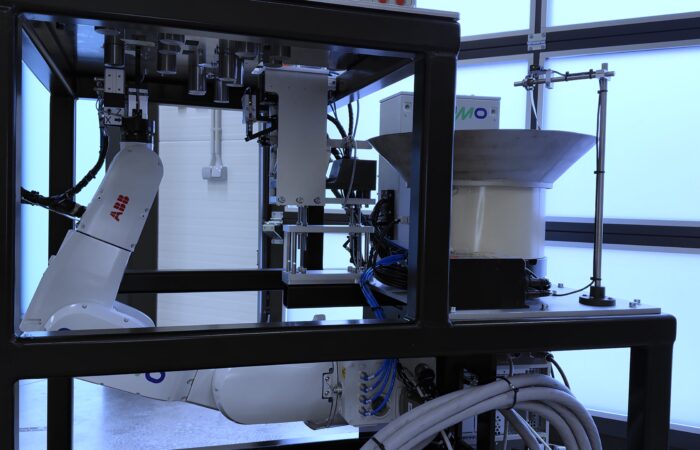

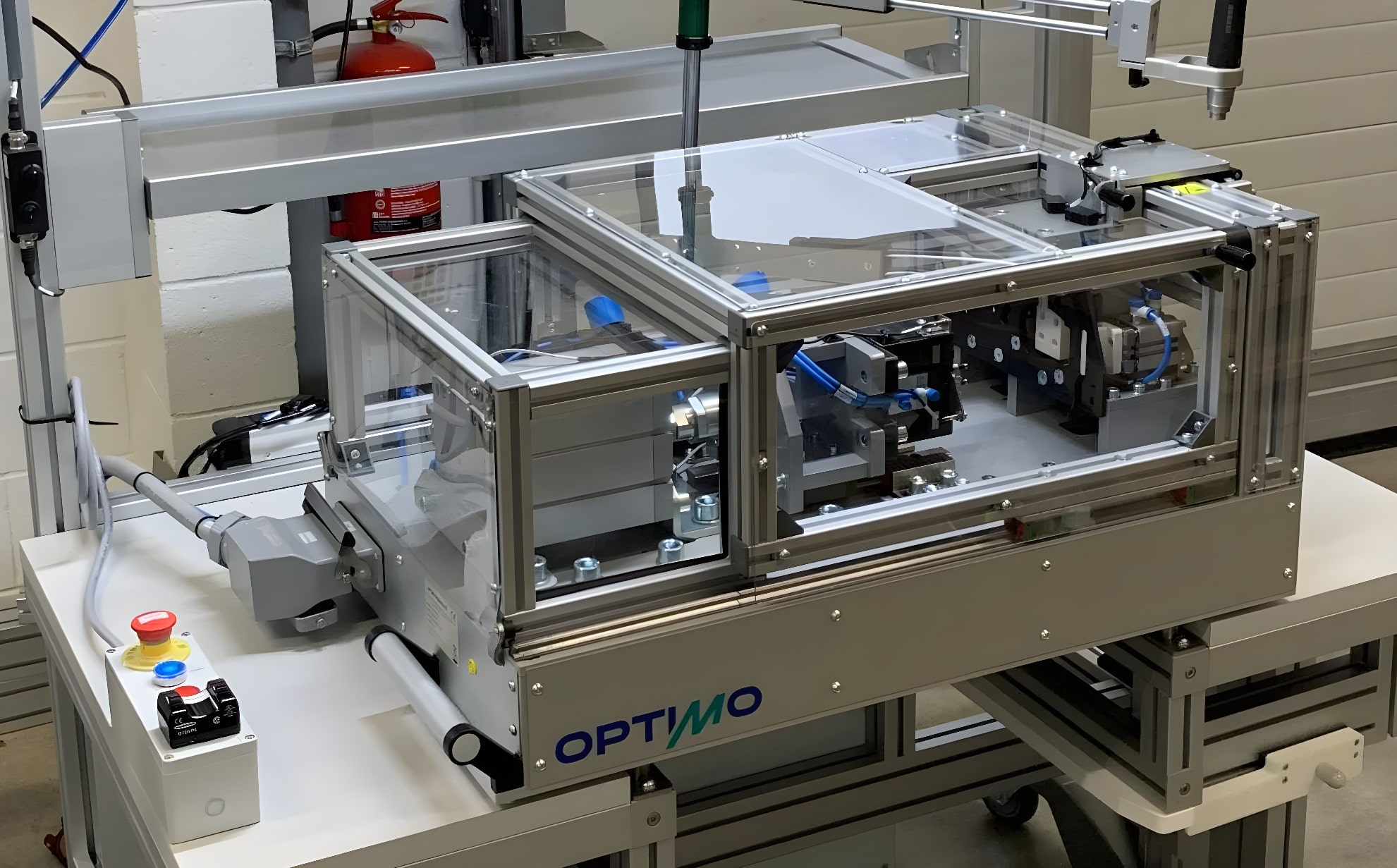

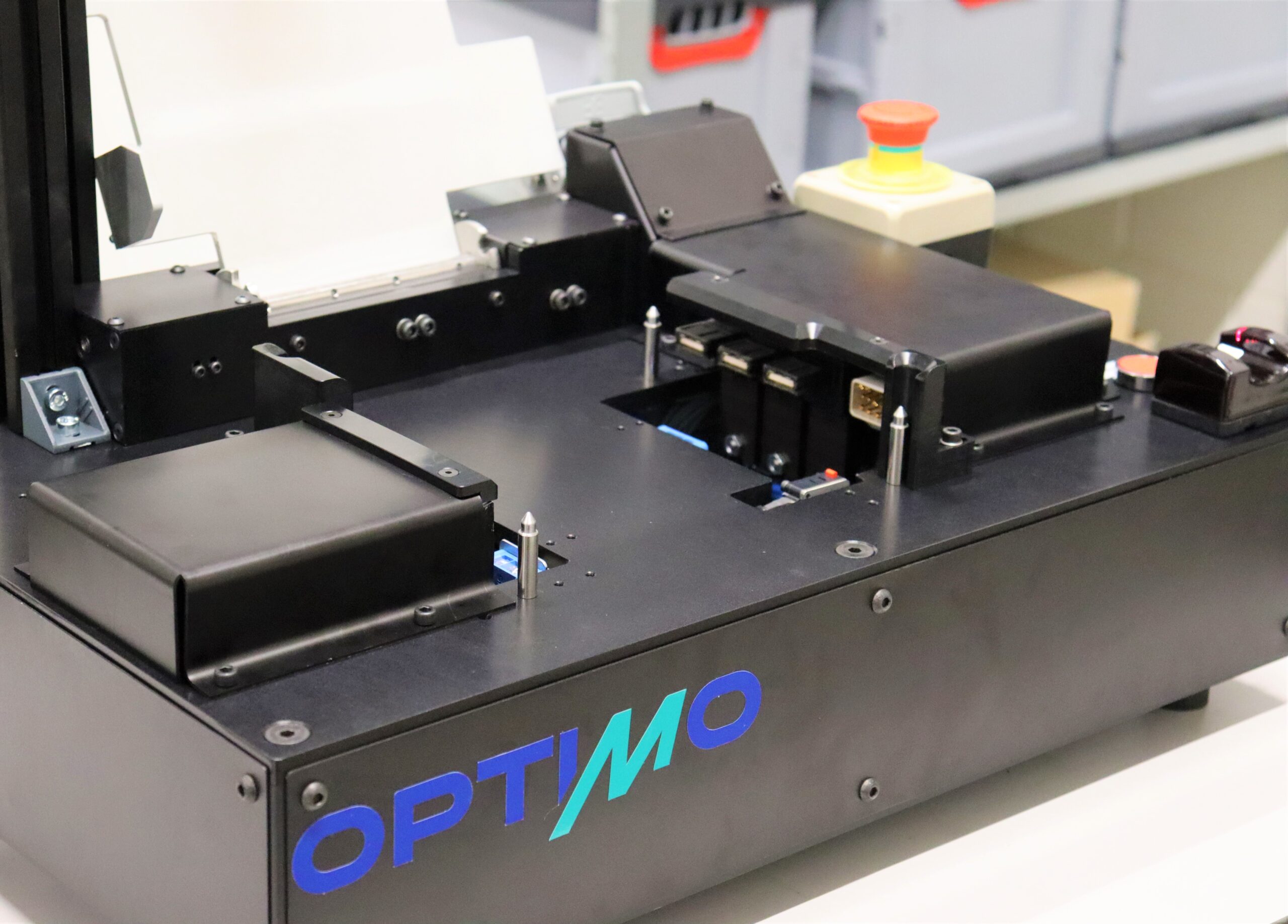

The project involves the development and production of specialized production assembly equipment, designed to facilitate the assembly of SD cards, thermal pads, and fixing screws. The equipment includes an electrical cabinet equipped with a Siemens S1200 programmable logic controller, Cognex camera systems, custom assembly fixtures, and integration with test equipment.

Solution

- Assembly fixture

- Screwing fixture

- Machine vision fixture

- Test fixture

Industry

Automotive, electronics

Products used

- Screwing solution

- Cognex camera systems

- Cognex scanners

Services

- Engineering (mechanical, electrical, pneumatics)

- Programming

- Machine building

- Installation

Machine building

The challenge

The solution

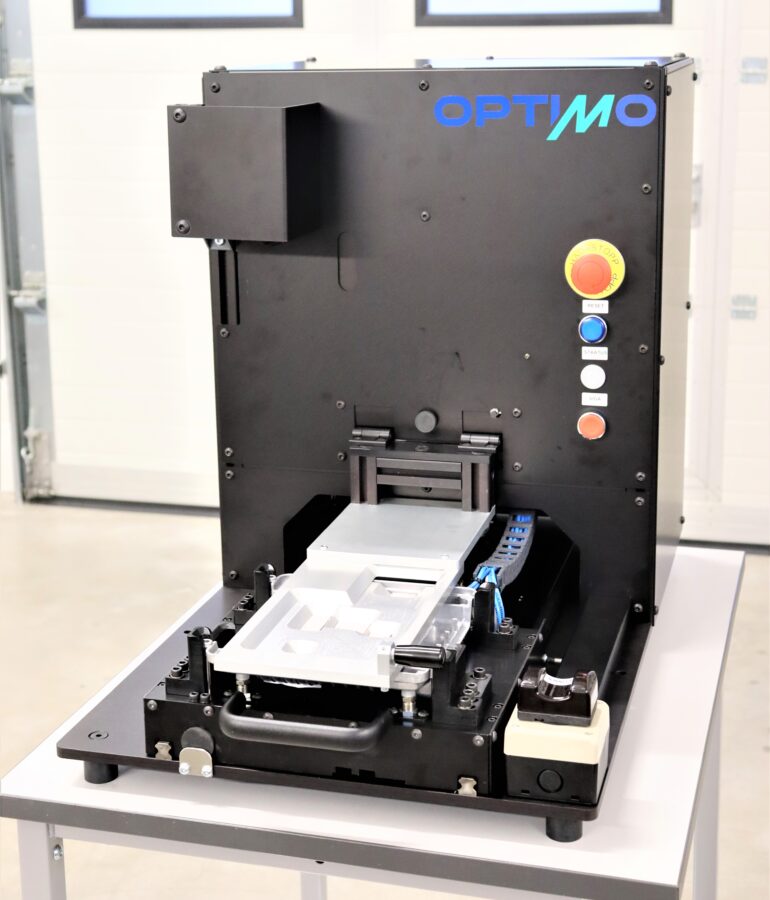

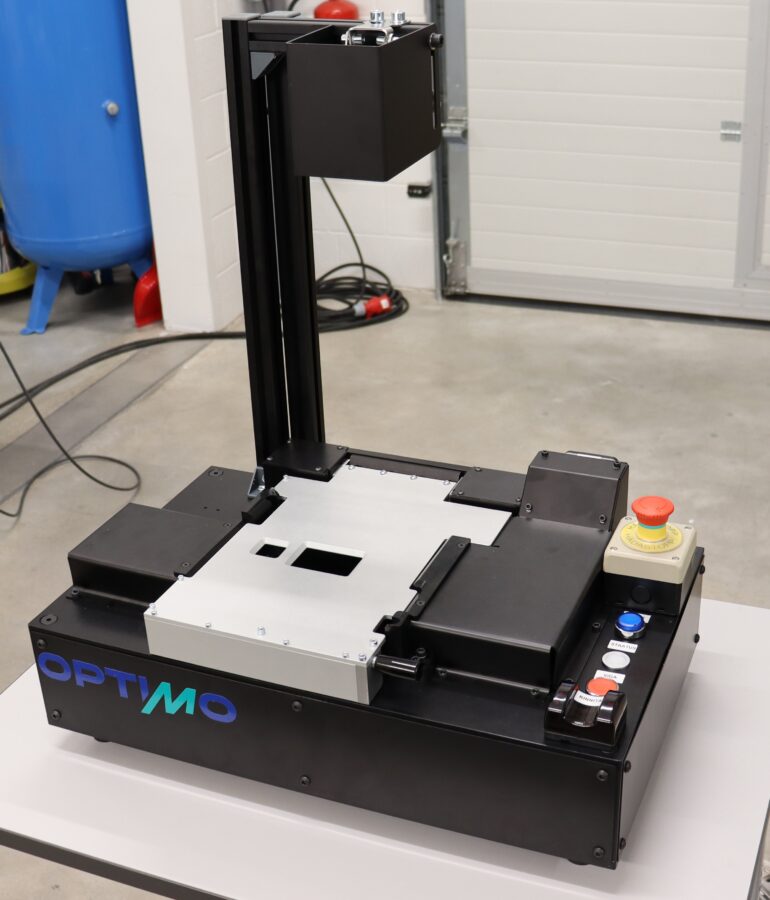

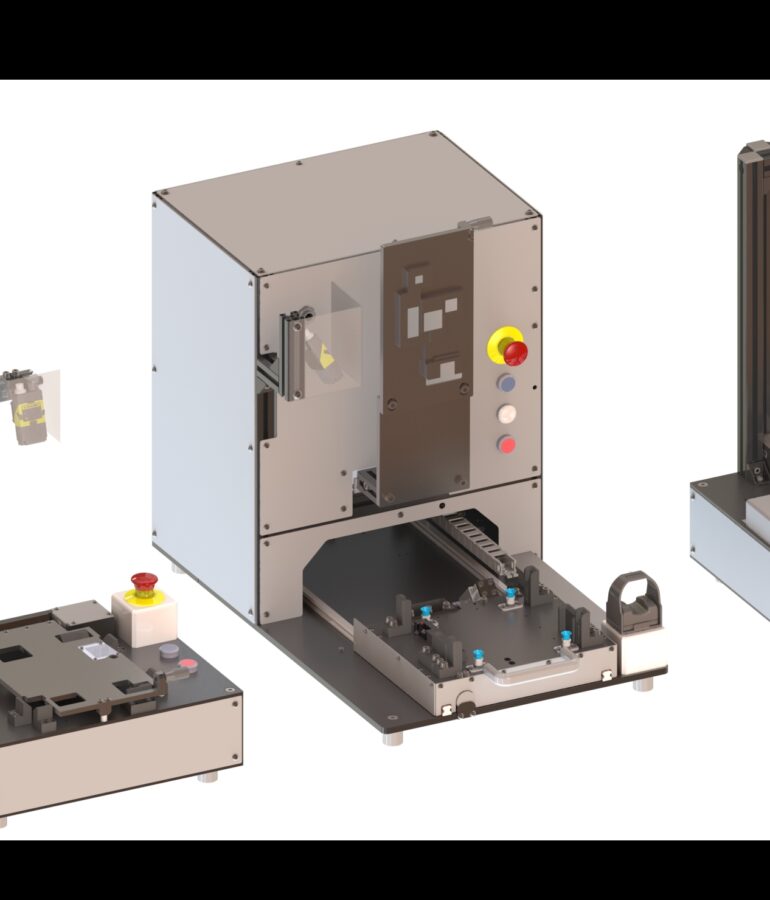

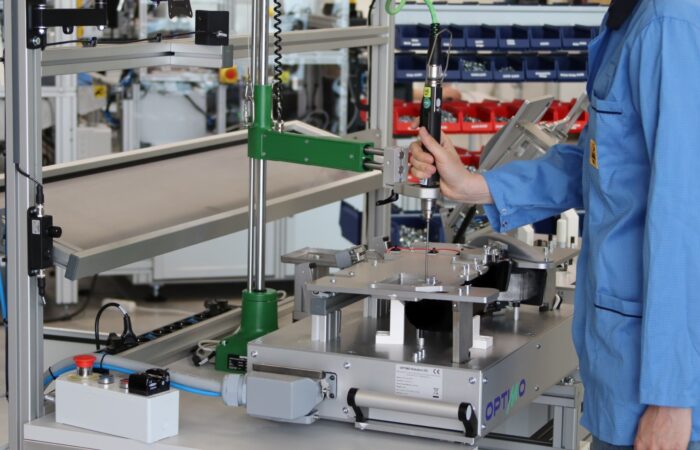

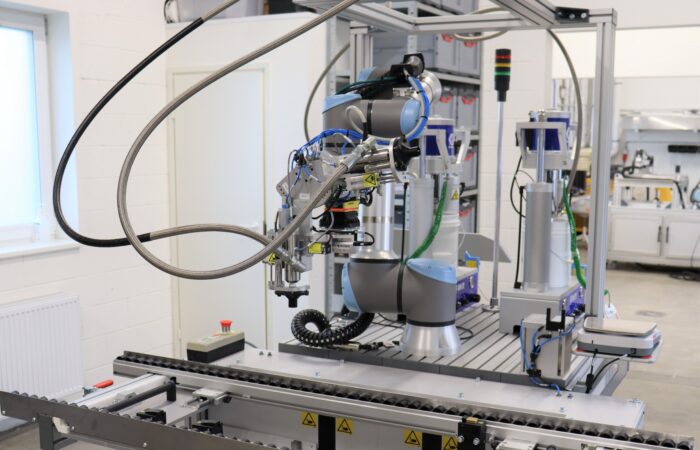

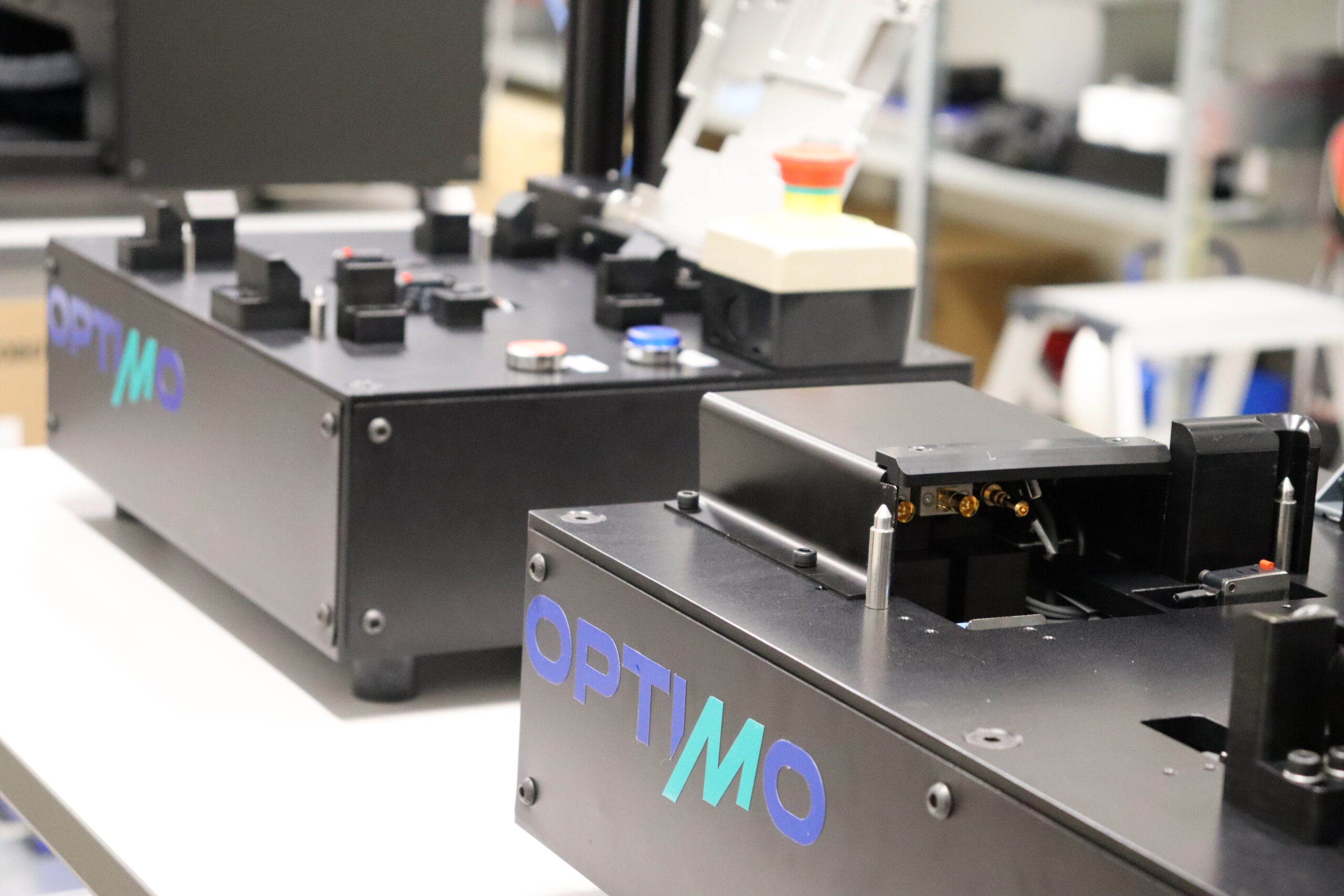

Fixtures for Electronics Product Assembly

Three specialized assembly fixtures were designed to constant workflows tailored to each stage of the product assembly. Each fixture has integrated electrical screwdrivers, vision systems, and 2D code scanning, along with mask locking, signal lights, and step-by-step assembly commands, to reduce operator errors.

The summary

Contact us!

Don't let your business fall behind, stay ahead of the curve with automation! We aim to respond within 24 hours!