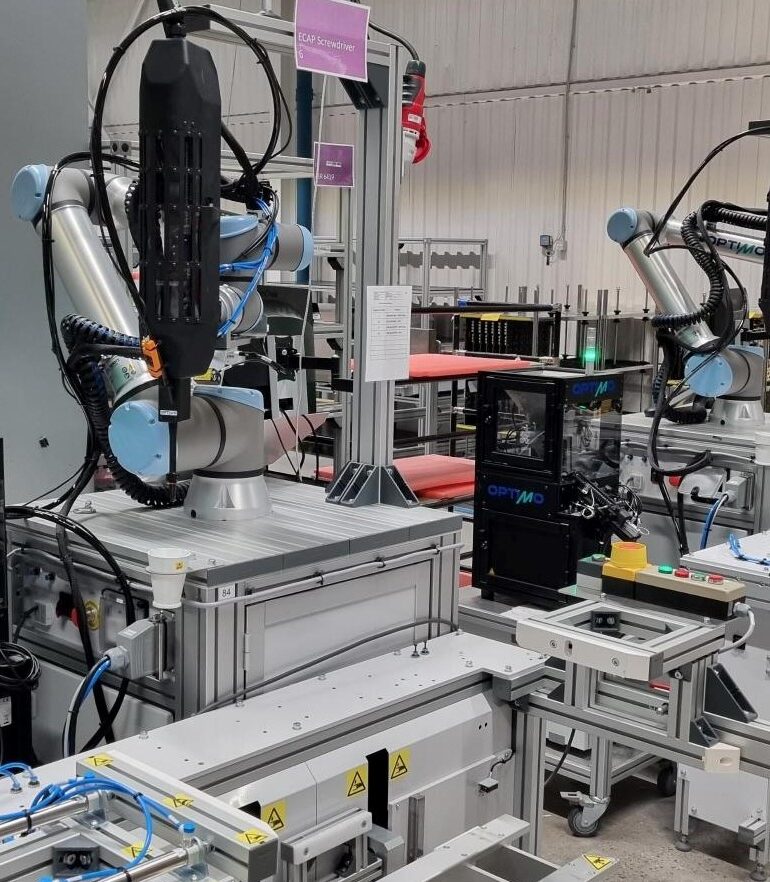

Cobot Screwdriving System

Robotic Screwdriver System

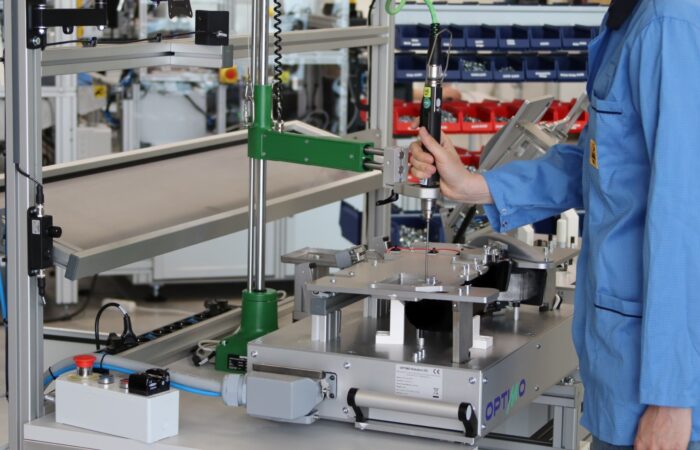

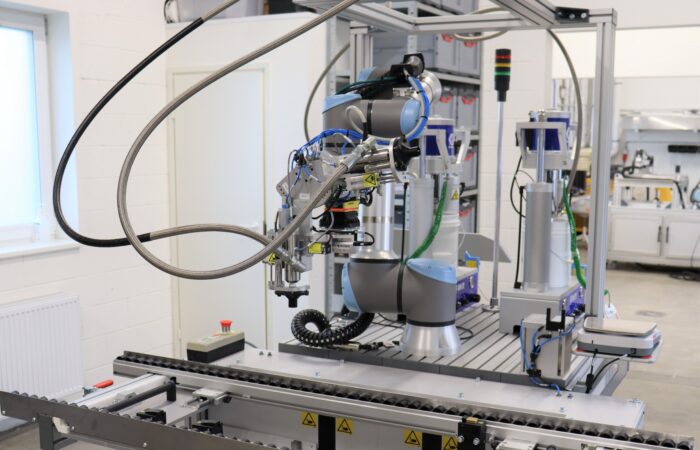

The project involves the development, programming, and production of specialized robotic assembly equipment, specifically designed for inserting, tightening, and re-tightening screws in large telecommunication products. This includes precise attachment of PCBs, antennas, and covers.

Solution

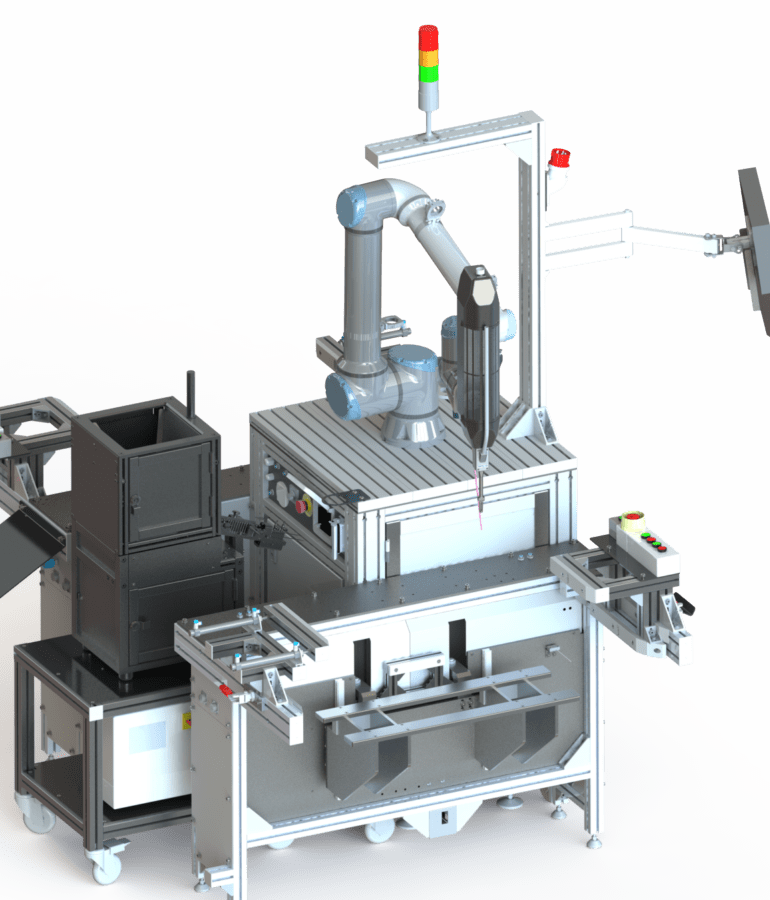

- Advanced Cobot Screwdriver Platform

- Product full positioning with laser distance sensor

- End-effector quick change system

- Trolley lifter with product locking

Industry

-Telecomminucation

Products used

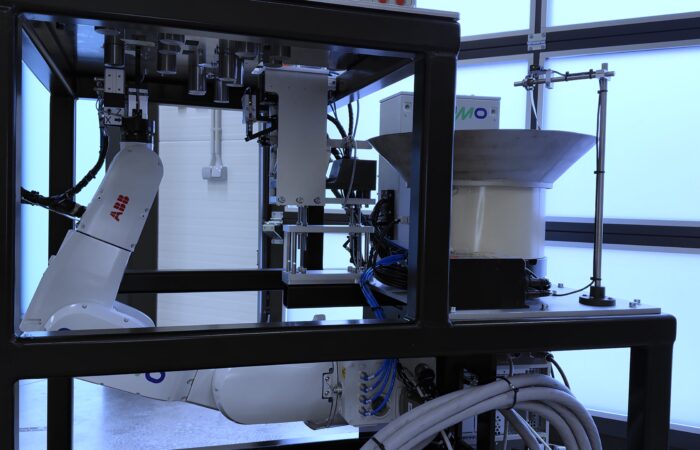

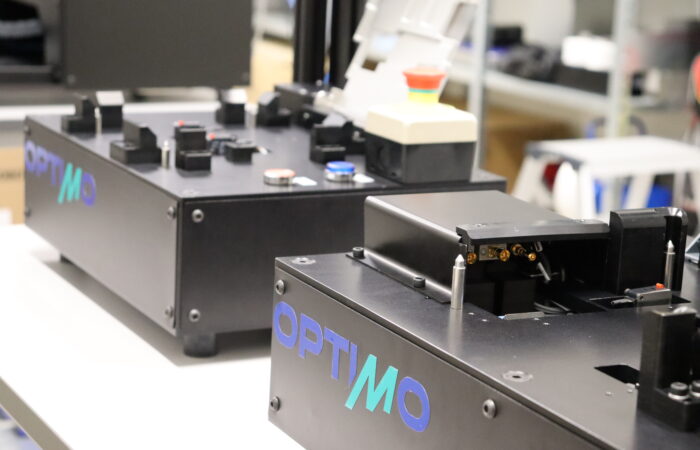

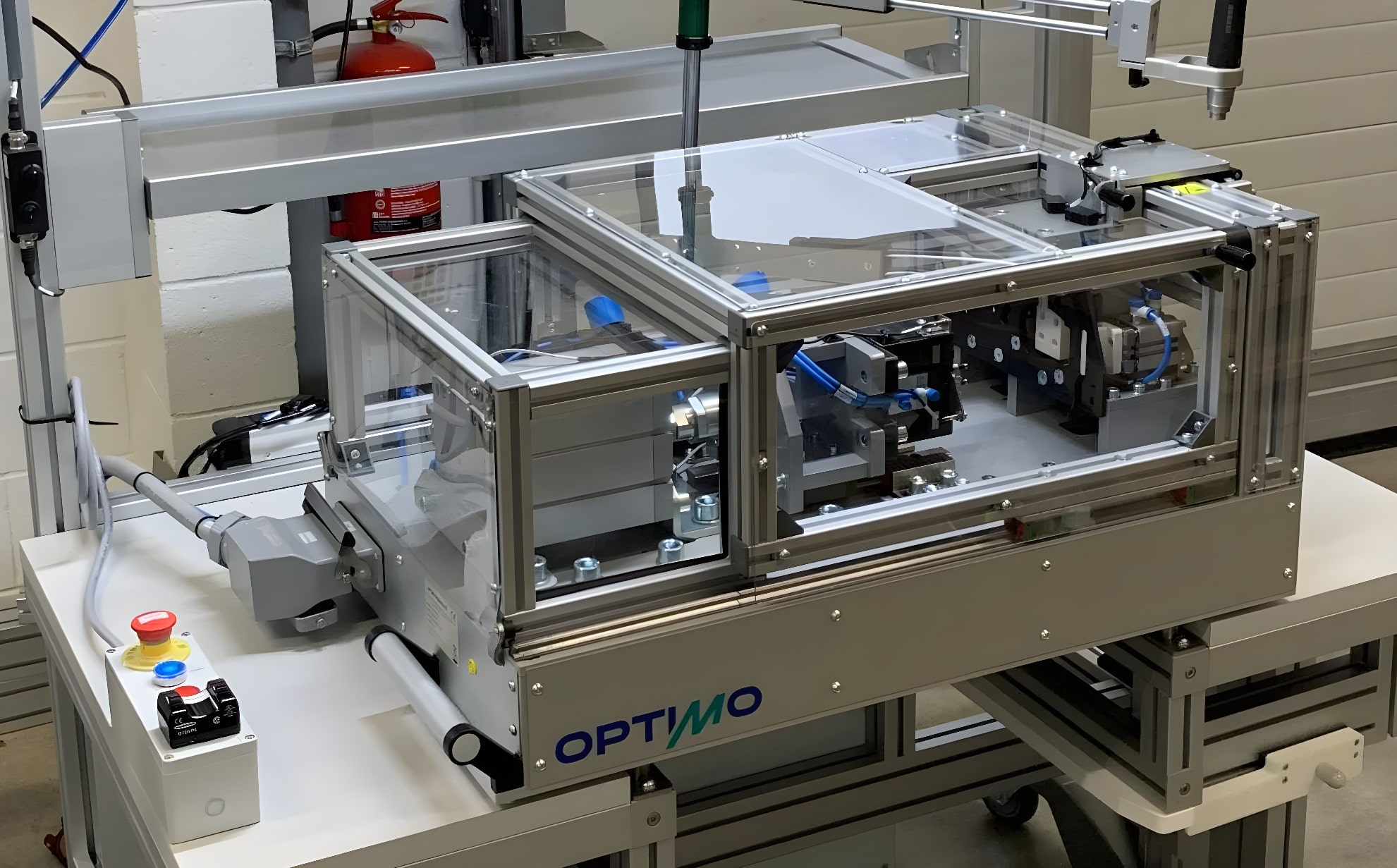

- OPTIMO Screwdriving System

- OPTIMO Screw Feeder

- OPTIMO URCAP Integration Module

- Universal Robots UR10e for Collaborative Operations

Services

- Engineering (mechanical, electrical, pneumatics)

- Programming

- Machine building

- Installation

The challenge

The solution

A CoBot-Integrated Screwdriving System with Universal Robots

Optimo Robotics responded by developing the OPTIMO Screwdriving System, which integrates a screwdriver, a screw feeder, a URCAP module, and a controller. Central to this system is the integration of Universal Robots, designed to operate in harmony with human workers using the CoBot concept, eliminating the need for security fences. To ensure precision and adaptability, the screwdriving system includes features such as a trolley lifting mechanism, a product fixing solution, and a laser distance sensor. These components work together to streamline the robot's positioning and task execution.

The summary

Robotic Screwdriving for Electronic Manufacturers

Optimo Robotics has engineered and produced an advanced, 'turnkey' robotic screwdriving platform, specifically designed to meet the demands of electronic manufacturers. By harnessing the capabilities of Universal Robots and the versatility of the OPTIMO Screwdriving System, we provide a solution that perfectly combines efficiency, safety, and adaptability. From detailed specifications to final implementation, our holistic approach ensures that each project is executed with precision, tailored to the unique needs of the telecommunications and electronics sectors.Contact us!

Don't let your business fall behind, stay ahead of the curve with automation! We aim to respond within 24 hours!