Screw-driving Workstation with Assembly Fixtures

Project description

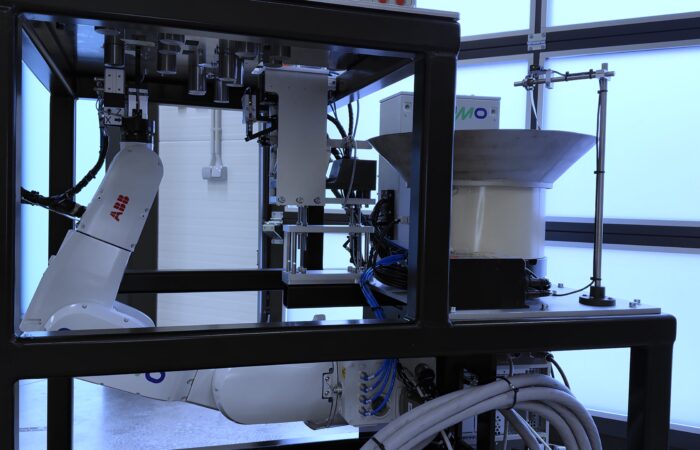

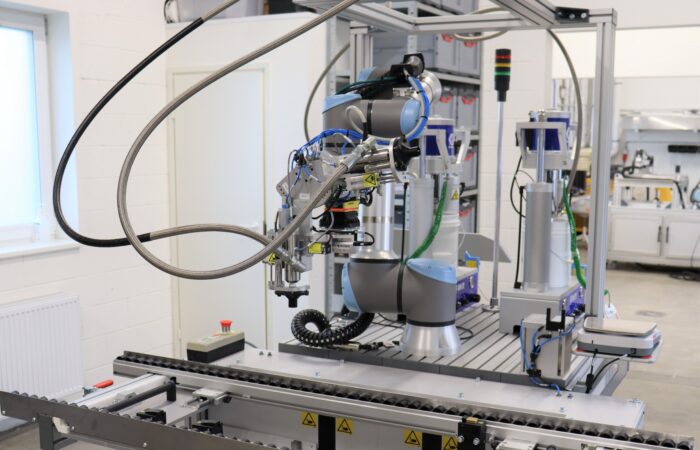

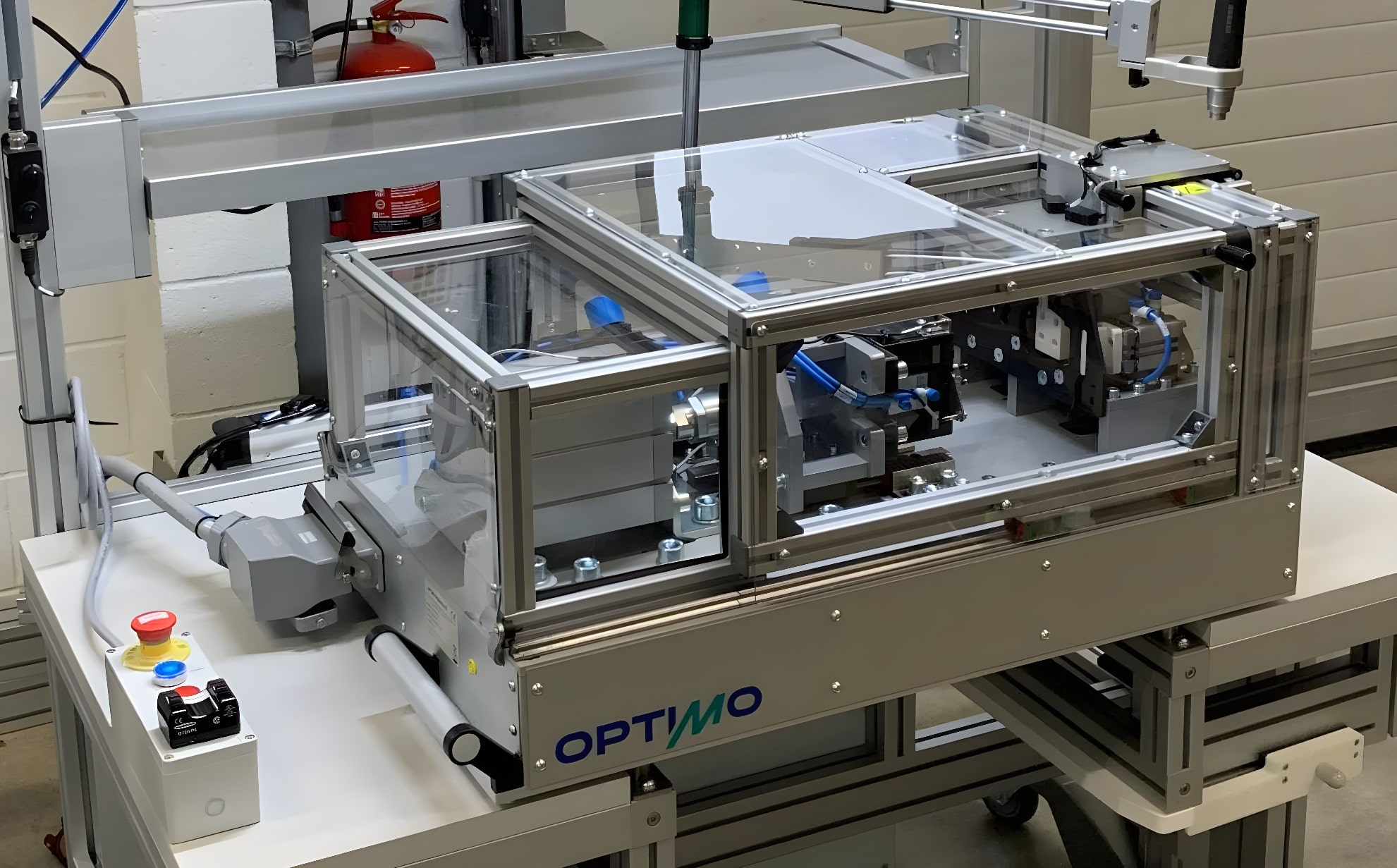

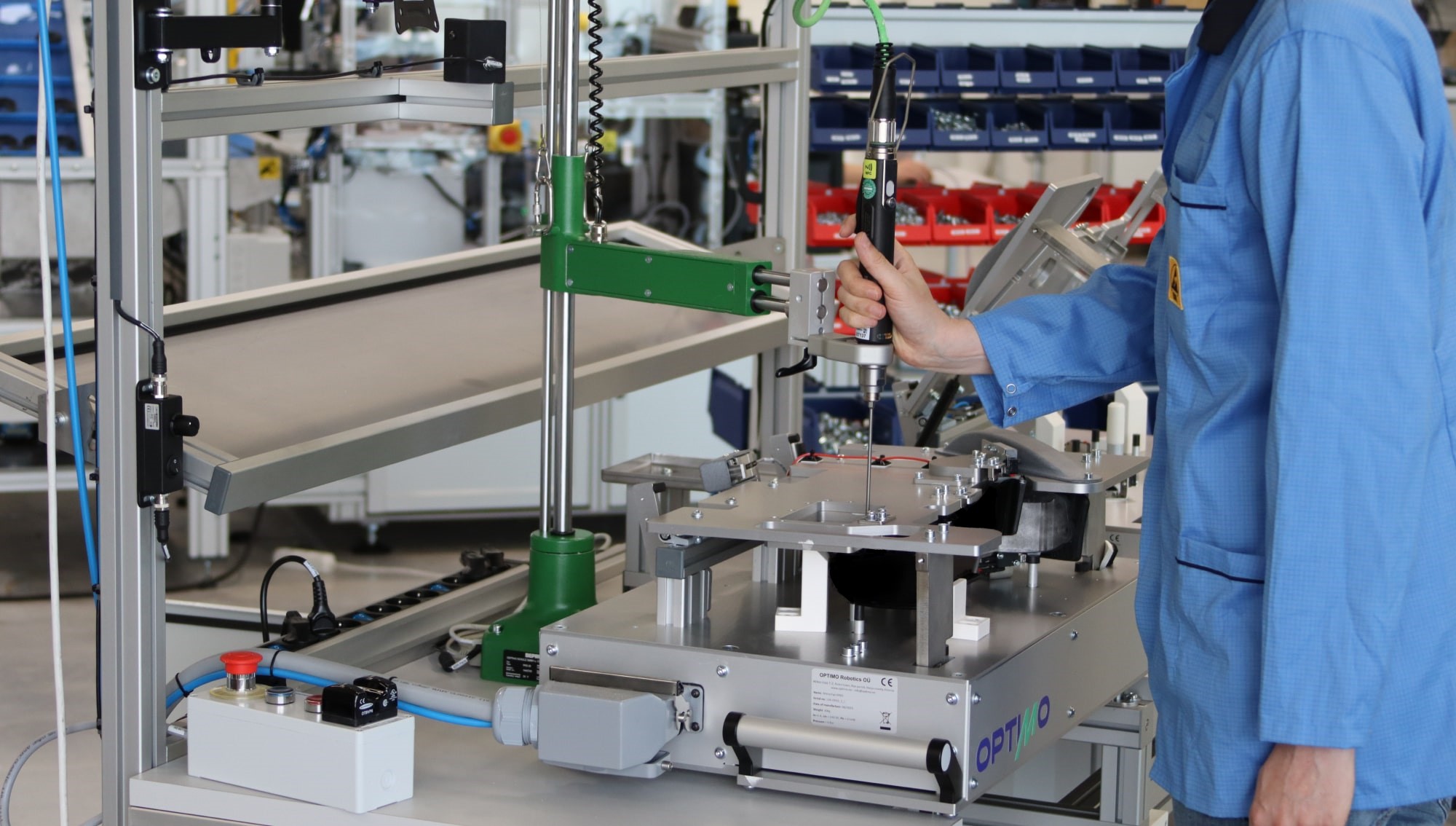

The project involves the development and production of specialized screwdriving and production assembly equipment, designed to facilitate the efficient assembly of plastic covers onto aluminum bodies. Following the assembly process, the parts will be securely fastened together using screws. The equipment includes an electrically height-adjustable workstation, an electrical cabinet equipped with a PLC, custom assembly fixtures, and integration with a screwdriver system.

Solution

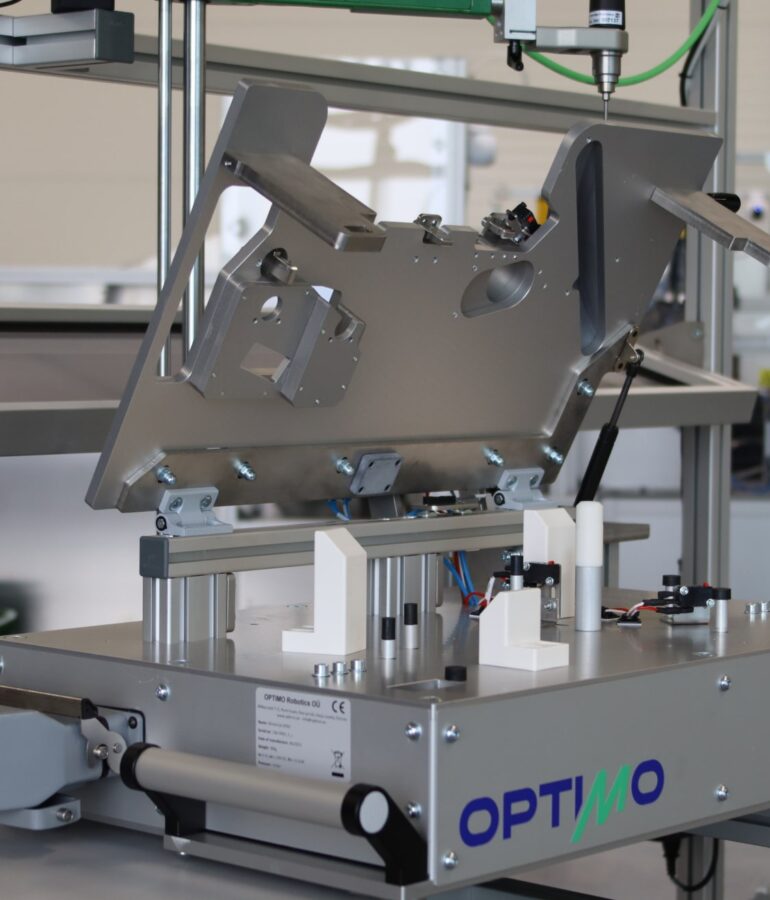

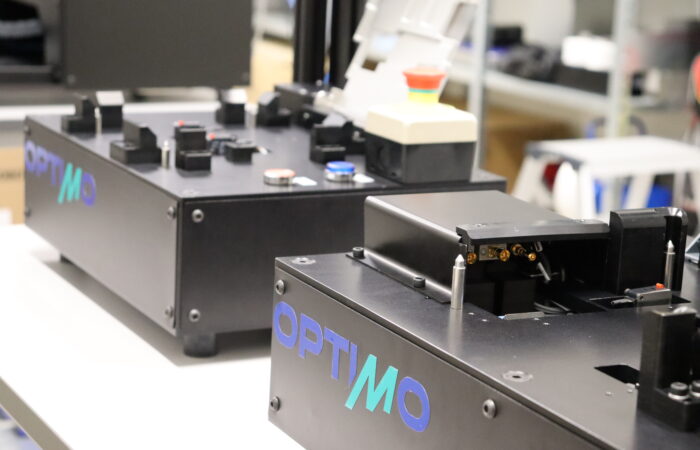

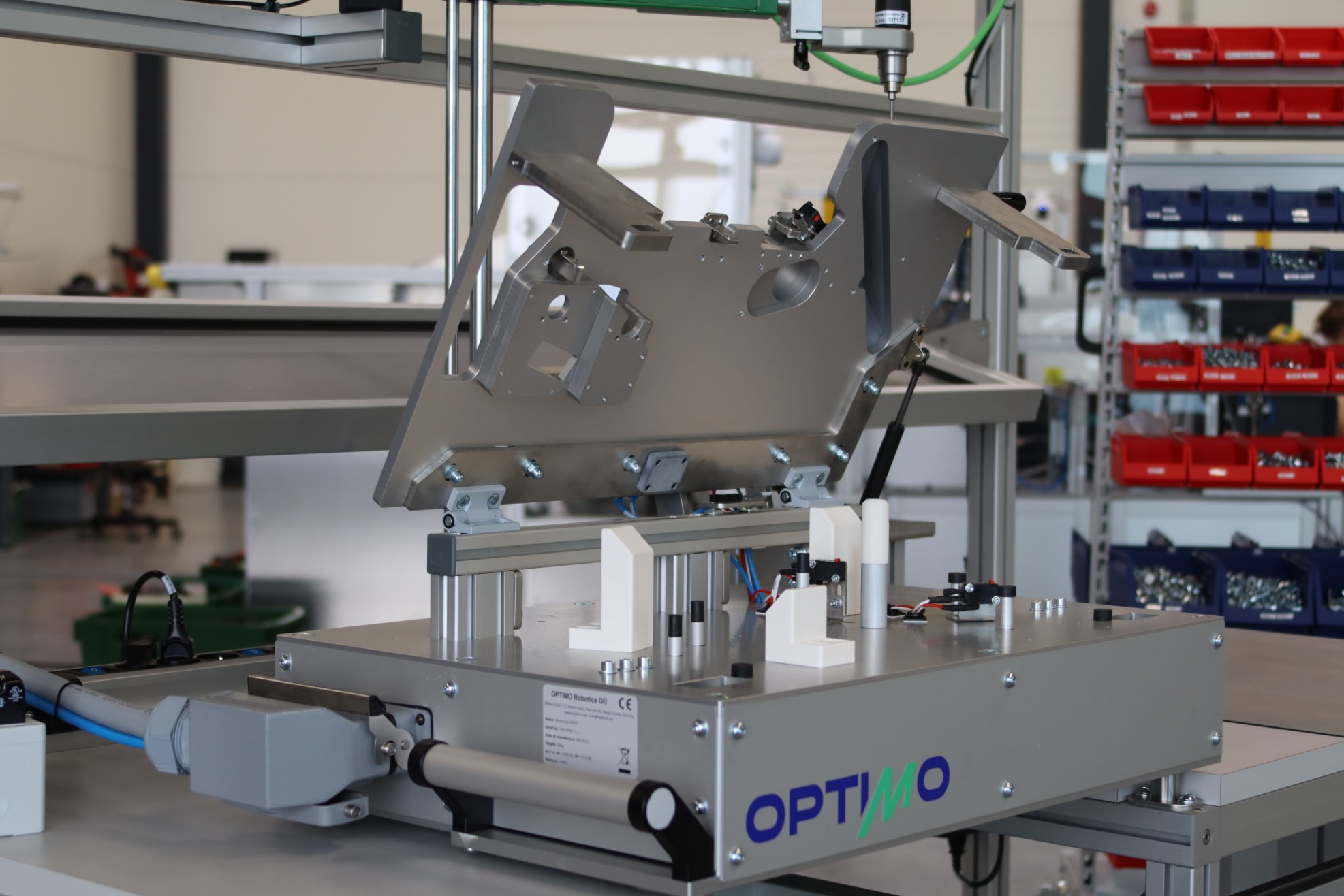

- Custom Screwdriving Fixtures with Integrated Screw Masks

- Controlled assembly sequence

- Trolleys for fixture changeover

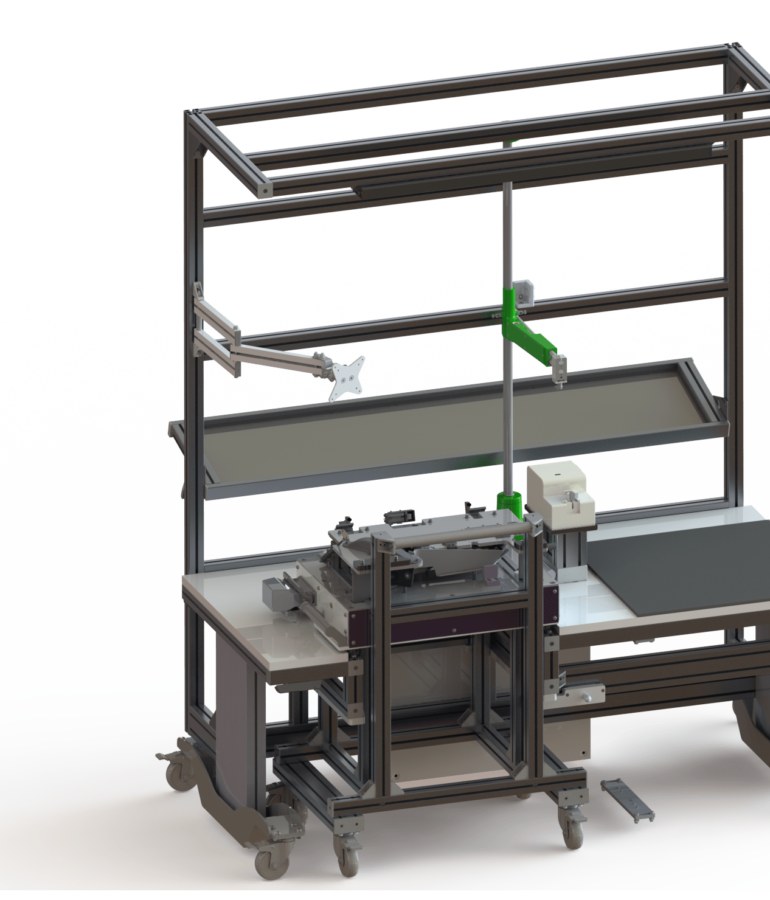

- Height-Adjustable ESD Workstation for Ergonomic Screwdriving

Industry

- Automotive and Electronics

Products used

- ESD Workstation for Screwdriving Tasks

- Screwing solution

Services

- Engineering (mechanical, electrical, pneumatics)

- Programming

- Machine building

- Installation

The challenge

The solution

Smart ESD Workstation with screwdriving and assembly process control

To address this challenge, a flexible solution was developed, consisting of a smart workstation tailored for precise screwdriving and assembly process control. This solution incorporated specialized assembly fixtures designed for both the left and right sides of the product, facilitating efficient assembly and screwing operations. The integration of mobile trolleys enhanced the flexibility and ergonomics of the workspace, allowing for easy transportation and accessibility of fixtures. The smart workstation featured height adjustment capabilities, ensuring ergonomic comfort and adaptability for operators of different statures.

The summary

Contact us!

Don't let your business fall behind, stay ahead of the curve with automation! We aim to respond within 24 hours!